Numerical simulation of influence of reservoir characteristics on heating process of enhanced geothermal system of horizontal well multi fractures

-

摘要:

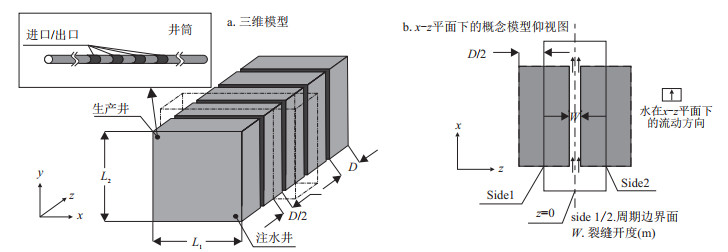

将石油天然气行业发展很成熟的水平井多裂隙开发技术用于增强型地热系统(EGS)可显著提高EGS的经济效益。本研究建立了三维EGS水平井多裂隙物理模型, 采用CFX模拟分析了在井间距以及裂隙间距等不同储层特征条件下EGS的运行性能, 揭示了不同储层特征对于EGS储层采热过程的影响机理。研究结果表明: ①裂隙间距是影响EGS工程运行寿命和开采率的关键因素, 在相同注水流量下, 较大的裂隙间距不易形成热穿透, 系统运行寿命更长, 但降低了储层开采率; 过小的裂隙间距易形成热穿透, 系统运行寿命短, 但开采率高。②井间距对裂隙中的流体流速影响显著, 随着井间距增加, 在相同开采时间下, 产流流体的温度不断升高, 系统的寿命也会随着井间距的增加而增加, 井间距的增大也意味着储层的体积也就更大, 从而有更多的热量可供开采, 因而提高了系统的运行寿命。研究结果可以为EGS储层的建造提供理论指导, 为实现商业化开采地热能做好理论准备。

Abstract:The horizontal well multi-fracture development technology, which is well-developed in the oil and gas industry, can significantly improve the economics of enhanced geothermal systems (EGS). In this paper, a three-dimensional horizontal-well multi-fracture physical model is established for EGS. The performances of EGS under different reservoir characteristics of well spacing and fracture spacing are analyzed by CFX simulation, and the influence mechanism of different reservoir characteristics on the heat recovery process of the EGS reservoir is revealed. The results show that: ①The fracture spacing is the key factor affecting the operating life and mining rate of EGS engineering. Under the same water injection flow, the larger the fracture spacing, the smaller the possibility of forming thermal permeability, the longer the system operation life, but the lower the reservoir recovery rate. The smaller the fracture spacing, the higher the thermal permeability, the shorter the system life, and the higher the reservoir recovery.②The well spacing has a significant effect on the fluid velocity in the fracture. As the well spacing increases, the temperature of the flow-producing fluid increases continuously during the same mining time, and the life of the system also increases. The increase in well spacing also means that the reservoir volume becomes large, so there is more geothermal energy for exploitation and longer life for the system for operating. The research can provide theoretical guidance for the construction of EGS reservoirs and provide theoretical preparation for the commercial exploitation of geothermal energy.

-

表 1 流体与岩石的物理参数

Table 1. Physical properties of fluid and rock

参数 名称 数值 ρs 岩石密度/(kg·m-3) 2 650 λs 岩石热导率/(W·m-1·K-1) 3.49 Cs 岩石比热容/(J·kg-1·K-1) 920 ρf 水的密度/(kg·m-3) 900 λf 水的热导率/(W·m-1·K-1) 0.606 9 Cf 水的比热容/(J·kg-1·K-1) 4 181.7 μ 高温下水的动力黏度/(mPa·s) 0.3 k 裂隙渗透率/m2 3×10-9 γ 裂隙孔隙度 1 W 裂隙开度/m 0.002 a 代表性的粗糙高度/m 0.014 L1 裂隙高度/m 400 L2 裂隙长度/m 400 Tinj 注水温度/K 333.15 D 岩体单元厚度/m 100 表 2 算例设置

Table 2. Design of cases

算例 储层温度分布:平均温度473.15 K 流量q/(kg·s-1) 裂隙间距/m 井间距/m 上表面温度/K 下表面温度/K 温度梯度/(K·100 m-1) 1 461.15 485.15 6 8 100 495.0 2 473.15 473.15 无 8 100 495.0 3 461.15 485.15 6 8 80 495.0 4 461.15 485.15 6 8 50 495.0 5 461.15 485.15 6 8 50 636.4 6 461.15 485.15 6 8 50 777.8 -

[1] 王贵玲, 张薇, 梁继运. 中国地热资源潜力评价[J]. 地球学报, 2017, 38(4): 449-450, 134, 451-459. https://www.cnki.com.cn/Article/CJFDTOTAL-DQXB201704002.htmWang G L, Zhang W, Liang J Y. Evaluation of geothermal resources potential in China[J]. Acta Geoscientica Sinica, 2017, 38(4): 449-450, 134, 451-459 (in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DQXB201704002.htm [2] 高红梅, 兰永伟, 赵延林. 花岗岩在围压和温度作用下渗透率变化规律研究[J]. 佳木斯大学学报: 自然科学版, 2017, 35(6): 955-958. doi: 10.3969/j.issn.1008-1402.2017.06.019Gao H M, Lan Y W, Zhao Y L. Study on permeability of granite under conditions of stress and temperature[J]. Journal of Jiamusi University: Natural Science Edition, 2017, 35(6): 955-958(in Chinese with English abstract). doi: 10.3969/j.issn.1008-1402.2017.06.019 [3] 许天福, 胡子旭, 李胜涛. 增强型地热系统: 国际研究进展与我国研究现状[J]. 地质学报, 2018, 92(9): 1936-1947. doi: 10.3969/j.issn.0001-5717.2018.09.012Xu T F, Hu Z X, Li S T. Enhanced geothermal system: International progresses and research status of China[J]. Acta Geologica Sinica, 2018, 92(9): 1936-1947(in Chinese with English abstract). doi: 10.3969/j.issn.0001-5717.2018.09.012 [4] 王贵玲, 张薇, 蔺文静. 全国地热资源调查评价与勘查示范工程进展[J]. 中国地质调查, 2018, 5(2): 1-7. https://www.cnki.com.cn/Article/CJFDTOTAL-DZDC201802001.htmWang G L, Zhang W, Lin W J. Project progress of survey, evaluation and exploration demonstration of national geothermal resource[J]. Geological Survey of China, 2018, 5(2): 1-7(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZDC201802001.htm [5] 王亚超, 窦斌, 喻勇, 等. 不同冷却方式下高温花岗岩巴西劈裂及声发射特性试验研究[J/OL]. 地质科技通报: 1-8[2022-05-11]. https:doi.org/10.19509/j.cnki.dzkq.2021.0028.Wang Y C, Dou B, Yu Y, et al. Experimental study on brazilian splitting and acoustic emission characteristics of high temperature granite under different cooling methods[J/OL]. Bulletin of Geological Science and Technology, 2021, doi: 10.19509/j.cnki.dzkq:[2022-05-11].2021.0028(in Chinese with English abstract). [6] 陈金龙, 罗文行, 窦斌, 等. 涿鹿盆地三维多裂隙地质模型地温场数值模拟[J]. 地质科技通报, 2021, 40(3): 22-33. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ202103003.htmChen J L, Luo W X, Dou B, et al. Numericalsimulation of geothermal field in a three-dimensional multi-fractured geological model of Zhuolu Basin[J]. Bulletin of Geological Science and Technology, 2021, 40(3): 22-33(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ202103003.htm [7] 汪集旸, 胡圣标, 庞忠和. 中国大陆干热岩地热资源潜力评估[J]. 科技导报, 2012, 30(32): 25-31 doi: 10.3981/j.issn.1000-7857.2012.32.002Wang J Y, Hu S B, Pang Z H. Estimate of geothermal resources potential for Hot dry rock in the continental area of china[J]. Science & Technology Review, 2012, 30(32): 25-31(in Chinese with English abstract). doi: 10.3981/j.issn.1000-7857.2012.32.002 [8] 张驰. 干热岩单裂隙渗流—传热实验与数值模拟研究[D]. 长春: 吉林大学, 2017.Zhang C. Experiment and numerical study of seepage heat transfer in a single fracture of hot dry rock[D]. Changchun: Jilin University, 2017(in Chinese with English abstract). [9] Jiang F, Luo L, Chen J. A novel three-dimensional transient model for subsurface heat exchange in enhanced geothermal systems[J]. International Communications in Heat and Mass Transfer, 2013, 41: 57-62. doi: 10.1016/j.icheatmasstransfer.2012.11.003 [10] 薛卉, 舒彪, 陈科平, 等. CO2基增强型地热系统中流体-花岗岩相互作用研究进展及展望[J]. 地质科技通报, 2021, 40(3): 45-53. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ202103005.htmXue H, Shu B, Chen K P, et al. Research progress of luid-granite interation CO2 basenhanced geothermal system[J]. Bulletin of Geological Science and Technology, 2021, 40(3): 45-53 (in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ202103005.htm [11] Huang W, Cao W, Jiang F. Heat extraction performance of EGS with heterogeneous reservoir: A numerical evaluation[J]. International Journal of Heat and Mass Transfer, 2017, 108: 645-657. doi: 10.1016/j.ijheatmasstransfer.2016.12.037 [12] 白兰兰, 陈建生, 王新建. 裂隙岩体热流模型研究[J]. 人民黄河, 2007, 29(5): 61-63. https://www.cnki.com.cn/Article/CJFDTOTAL-RMHH200705029.htmBai L L, Chen J S, Wang X J. Study on thermal flow model of fractured rock mass[J]. Yellow River, 2007, 29(5): 61-63(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-RMHH200705029.htm [13] Zeng Y C, Wu N Y, Su Z, et al. Numerical simulation of heat production potential from hot dry rock by water circulating through a novel single vertical fracture at Desert Peak geothermal field[J]. Energy, 2013, 63: 268-282. doi: 10.1016/j.energy.2013.10.036 [14] Guo B, Fu P, Hao Y. Thermal drawdown-induced flow channeling in a single fracture in EGS[J]. Geothermics, 2016, 61: 46-62. doi: 10.1016/j.geothermics.2016.01.004 [15] Kohl T, Evansi K F, Hopkirk R J. Coupled hydraulic, thermal and mechanical considerations for the simulation of hot dry rock reservoirs[J]. Geothermics, 1995, 24(3): 345-359. doi: 10.1016/0375-6505(95)00013-G [16] Rutqvist J, Wu Y S, Tsang C F. A modeling approach for analysis of coupled multiphase fluid flow, heat transfer, and deformation in fractured porous rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2002, 39(4): 429-442. doi: 10.1016/S1365-1609(02)00022-9 [17] Asai P, Panja P, McLennan J. Effect of different flow schemes on heat recovery from enhanced geothermal systems (EGS)[J]. Energy, 2019, 175: 667-676. doi: 10.1016/j.energy.2019.03.124 [18] Chen Y, Ma G, Wang H. Heat extraction mechanism in a geothermal reservoir with rough-walled fracture networks[J]. International Journal of Heat and Mass Transfer, 2018, 126: 1083-1093. doi: 10.1016/j.ijheatmasstransfer.2018.05.103 [19] Zeng Y C, Wu N Y, Su Z. Numerical simulation of electricity generation potential from fractured granite reservoir through a single horizontal well at Yangbajing geothermal field[J]. Energy, 2014, 65: 472-487. doi: 10.1016/j.energy.2013.10.084 [20] Zeng Y, Zhan J, Wu N. Numerical investigation of electricity generation potential from fractured granite reservoir by water circulating through three horizontal wells at Yangbajing geothermal field[J]. Applied Thermal Engineering, 2016, 104: 1-15. doi: 10.1016/j.applthermaleng.2016.03.148 [21] Zeng Y C, Zhan J M, Wu N Y. Numerical investigation of electricity generation potential from fractured granite reservoir through a single vertical well at Yangbajing geothermal field[J]. Energy, 2016, 114: 24-39. doi: 10.1016/j.energy.2016.07.153 [22] Zeng Y C, Zhan J M, Wu N Y. Numerical simulation of electricity generation potential from fractured granite reservoir through vertical wells at Yangbajing geothermal field[J]. Energy, 2016, 103: 290-304. doi: 10.1016/j.energy.2016.02.123 [23] Cheng H D, Ghassemi A, Detournay E. Integral equation solution of heat extraction from a fracture in hot dry rock[J]. International Journal for Numerical & Analytical Methods in Geomechanics, 2001, 25(13): 1327-1338. [24] 田鲁鲁. 裂隙岩体渗流—传热耦合模型试验及数值模拟研究[D]. 北京: 北京交通大学, 2010.Tian L L. Experimental and numerical study on the thermo-hydrological coupling of fractured rocks[D]. Beijing: Beijing Jiaotong University, 2010(in Chinese with English abstract). [25] Fox D B, Sutter D, Beckers K F, et al. Sustainable heat farming: Modeling extraction and recovery in discretely fractured geothermal reservoirs[J]. Geothermics, 2013, 46(4): 42-54. [26] Tenma N, Yamaguchi T, Zyvoloski G. The Hijiori Hot Dry Rock test site, Japan: Evaluation and optimization of heat extraction from a two-layered reservoir[J]. Geothermics, 2008, 37(1): 19-52. doi: 10.1016/j.geothermics.2007.11.002 [27] Yamashita M, Yamaguchi T, Kuriyagawa M. An estimation of fracture width of an artificial fracture made by laboratory hydraulic fracturing test[J]. Journal of the Mining & Materials Processing Institute of Japan, 1996, 112(9): 631-637. [28] Yamashita M, Yamaguchi T, Kuriyagawa M. Estimation of the fracture aperture and shape created by massive hydraulic fracturing test[J]. Shigen-to-Sozai, 1997, 113(4): 247-253. doi: 10.2473/shigentosozai.113.247 [29] Li M, Gou Y, Hou Z. Investigation of a new HDR system with horizontal wells and multiple fractures using the coupled wellbore-reservoir simulator TOUGH2MP-WELL/EOS3[J]. Environmental Earth Sciences, 2015, 73(10): 6047-6058. doi: 10.1007/s12665-015-4242-9 [30] 胡剑, 苏正, 吴能友. 增强型地热系统垂直裂隙热储热开采过程数值模拟[J]. 可再生能源, 2014, 32(6): 829-835. https://www.cnki.com.cn/Article/CJFDTOTAL-NCNY201406019.htmHu J, Su Z, Wu N Y. Numerical simulation of vertical fractures heat mining process ofthe enhanced geothermal system[J]. Renewable Energy Resources, 2014, 32(6): 829-835(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-NCNY201406019.htm [31] 袁益龙, 侯兆云, 雷宏武. 增强型地热系统井筒-储层耦合数值模拟分析[J]. 可再生能源, 2015, 33(3): 421-428. https://www.cnki.com.cn/Article/CJFDTOTAL-NCNY201503015.htmYuan Y L, Hou Z Y, Lei H W. Numerical simulation analysis of wellbore-reservoir coupling of EGS[J]. Renewable Energy Resources, 2015, 33(3): 421-428(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-NCNY201503015.htm -

下载:

下载: