Application of drag reduction technology of large section rectangular pipe jacking:A case study of rectangular jacking of Suzhou comprehensive pipe rack

-

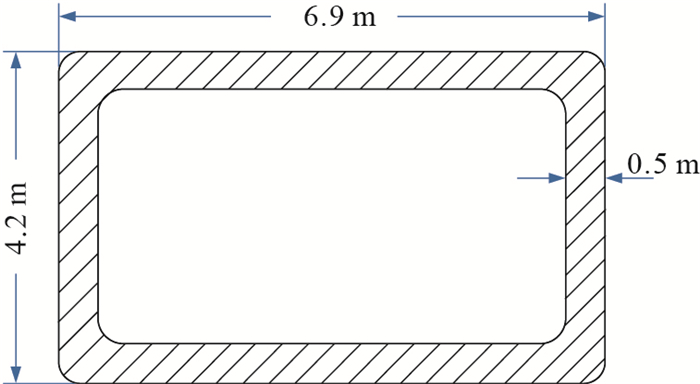

摘要: 以苏州城北路人民路段综合管廊矩形顶管工程为例,分析了影响矩形顶管顶进力的关键因素,提出了管节配重、管节涂蜡和管节注浆等综合减阻方法以降低管壁摩阻力。在管节内放置重物平衡管节所受周围泥浆的浮力;通过涂蜡和喷蜡使管壁光滑,降低管壁与周围介质的摩擦系数;选择合适的材料和配比配制适合地层的泥浆,调整注浆量和注浆压力,使管节周围形成完好的泥浆套。基于实测顶进力与理论计算值的对比分析表明,管壁单位面积摩阻力降低了40%左右,证实该综合减阻方法解决了人民路段矩形顶管顶进力过大的问题。Abstract: Based on the rectangular pipe jacking project of people′s section of Chengbei Road in Suzhou, we analyzed the key factors affecting the jacking force of rectangular pipe jacking, and proposed comprehensive drag reduction methods about pipe weight, wax and grouting to reduce the wall friction resistance. Weights were placed inside the pipe to balance the buoyancy of the mud around the pipe. The surface of the pipe was painted with much wax, thus reducing the friction coefficient between the wall and surrounding medium. Also, we chose suitable materials and proportion to prepare the mud appropriate for the ground, and adjusted the grouting amount and pressure so as to form a good "mud jacket" around the pipe. Finally, by comparing the measured jacking force with the theoretical calculation value, we found that the friction resistance per unit area of the pipe wall was reduced by about 40%, solving the problem of excessive jacking force of rectangular pipe jacking in people′s section.

-

表 1 顶管管道与其周围土层的摩擦系数

Table 1. Coefficient of friction between the jacking pipe and the surrounding soil

土层类型 湿土层摩擦系数 干土层摩擦系数 黏土、亚黏土 0.2~0.3 0.4~0.5 砂土、亚砂土 0.3~0.4 0.5~0.6 表 2 各种土质的部分计算参数

Table 2. Calculation parameters of soil property

土质 fk/(kN·m-2) fw 软弱土 4~10 0.2 普通土 8~14 0.3 硬质土 12~25 0.4 表 3 采用触变泥浆时管壁单位面积平均摩阻力

Table 3. Average friction resistance per unit area of pipe wall when thixotropic mud is used

摩阻力/(kN·m-2) 黏性土 粉土 粉、细砂土 中、粗砂土 钢筋混凝土管 3.0~5.0 5.0~8.0 8.0~11.0 11.0~16.0 钢管 3.0~4.0 4.0~7.0 7.0~10.0 10.0~13.0 注:当触变泥浆技术成熟可靠,管外壁能形成和保持稳定、连续的泥浆套时,摩阻力可直接取3.0~5.0 kN/m2 表 4 粉砂、粉土地层对触变泥浆性能的要求

Table 4. Requirements on the properties of thixotropic mud for silty sand and silty soil layers

地层 工程特点描述 泥浆性能要求 泥浆黏度/s API滤失量/(mL·30min-1) 粉砂、粉土 地层空隙、孔隙大,地层胶结弱 泥浆宜具有较好的抗滤失性能 >45 < 15 表 5 泥浆配比正交实验

Table 5. Orthogonal experiment of mud ratio

实验序号 膨润土φB/% CMC φB/% 烧碱φB/% PHP φB/% 黏度/s 失水量/(mL·30-1min-1) 1 5 0.5 0.5 0.3 36 17 2 5 1.0 1.0 0.6 48 12 3 5 1.5 1.5 0.9 49 13 4 7.5 0.5 1.0 0.9 37 14 5 7.5 1.0 1.5 0.3 50 13 6 7.5 1.5 0.5 0.6 62 10 7 10 0.5 1.5 0.6 68 12 8 10 1.0 0.5 0.9 72 10 9 10 1.5 1.0 0.3 78 8 表 6 现场采用优质触变泥浆配比及性能

Table 6. High quality thixotropic mud ratio and properties adopted on site

采用触变泥浆 膨润土φB/% CMC φB/% 烧碱φB/% PHP φB/% 黏度/s 失水量/(mL·30-1min-1) 一般地段泥浆 5 1.0 1.0 0.6 48 12 特殊地段泥浆 7.5 1.5 1.0 0.6 62 10 -

[1] 马保松.非开挖工程学[M].北京:人民交通出版社, 2008. [2] 王福芝, 曾聪, 孔耀祖.大直径长距离顶管润滑泥浆方案研究[J].地质科技情报, 2016, 35(2):54-57. http://www.cnki.com.cn/Article/CJFDTotal-DZKQ201602012.htm [3] 李超, 钟祖良, 刘新荣, 等.复杂接触条件下超长距离混凝土顶管-围岩摩擦特性及现场卡管处置验证研究[J].岩石力学与工程学报, 2019, 38(6):1197-1208. http://www.cnki.com.cn/Article/CJFDTotal-YSLX201906011.htm [4] 黄建华, 陈月香, 王蕴晨, 等.大断面顶管工程减摩泥浆配合比实验研究[J].福建工程学院学报, 2019, 17(3):212-218. http://www.cnki.com.cn/Article/CJFDTotal-JZGZ201903002.htm [5] 杨红军, 荣亮, 徐虎城.超大断面矩形顶管减阻技术在郑州市下穿中州大道隧道工程中的应用[J].隧道建设, 2016, 36(4):458-464. http://www.cnki.com.cn/Article/CJFDTotal-JSSD201604015.htm [6] 谢尚兵.富水砂砾层长距离大直径顶管减阻施工技术[J].工业技术创新, 2016, 3(5):969-972. http://www.cnki.com.cn/Article/CJFDTotal-GYJS201605038.htm [7] 王明胜, 刘大刚.顶管隧道工程触变泥浆性能试验及减阻技术研究[J].现代隧道技术, 2016, 53(6):182-189. http://www.cnki.com.cn/Article/CJFDTOTAL-XDSD201606024.htm [8] Reilly C C, Orr T L L.Physical modelling of the effect of lubricants in pipe jacking[J].Tunnelling and Underground Space Technology, 2017, 63:44-53. http://cn.bing.com/academic/profile?id=e25b8de1e407318f339a0d1ee9fcfeea&encoded=0&v=paper_preview&mkt=zh-cn [9] 张鹏, 谈力昕, 马保松.考虑泥浆触变性和管土接触特性的顶管摩阻力公式[J].岩土工程学报, 2016, 39(11):2043-2049. http://www.cnki.com.cn/Article/CJFDTotal-YTGC201711014.htm [10] 李剑, 张鹏, 李志宏.顶管施工润滑泥浆压力引起的土体附加应力计算[J].地质科技情报, 2016, 35(2):23-27. http://www.cnki.com.cn/Article/CJFDTotal-DZKQ201602006.htm [11] 中国地质大学.顶管施工技术及验收规范(试行)[S].北京: 人民交通出版社, 2007. [12] 陈永龙.大截面矩形顶管掘进技术在地铁工程中的应用[J].中国市政工程, 2008, 2(2):68-70. http://www.cnki.com.cn/Article/CJFDTotal-ZGSZ200802031.htm [13] 熊翦.矩形顶管关键受力分析[D].北京: 中国地质大学(北京), 2013. [14] 荣亮, 杨红军.郑州市下穿中州大道超大断面矩形隧道顶管姿态控制技术[J].隧道建设, 2015, 35(10):1338-1344. http://www.cnki.com.cn/Article/CJFDTotal-JSSD201510028.htm -

下载:

下载: