Study on permeability law of water-based polymer drilling fluid containing CaCl2 in wellbore formation

-

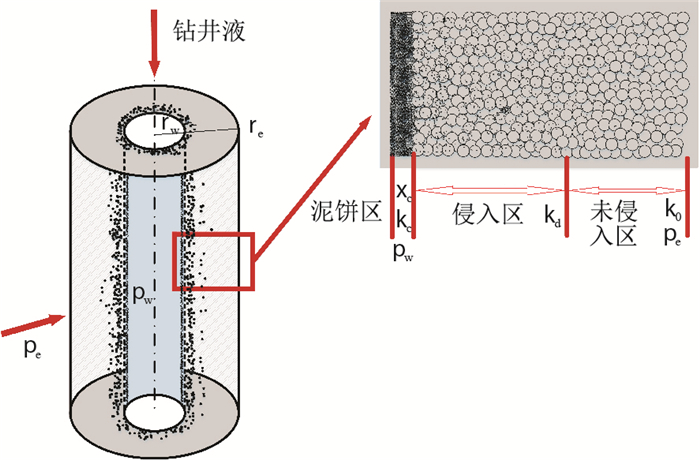

摘要: 利用微生物诱导碳酸钙沉积(MICP)技术来提高油气井固井二界面胶结质量近年来受到了越来越多的重视。当前,针对3 000 m以浅油气井已实现了含成矿微生物的固井水泥浆技术。为了使固井水泥浆滤液中的成矿微生物在二界面处高效发挥MICP作用以提高二界面胶结质量,还需在钻井过程中利用钻井液携带CaCl2的渗透向井周地层中预先注入一定量的钙源。因此,有必要研究含CaCl2钻井液在井周地层的渗透规律,从而合理控制CaCl2的注入量和钻井成本。基于此,以当前常用的环保水基聚合物钻井液为基本载体,综合考虑钻井液渗透时在井壁处泥饼动态形成机理、井周地层物性参数变化规律以及含CaCl2水基聚合物钻井液流变性等因素,利用理论计算与模拟实验相结合的方法,建立了含CaCl2水基聚合物钻井液滤液沿井周地层渗透量及渗透距离的定量预测模型。该预测模型的计算结果与模拟实验测试结果吻合程度较高,证实该预测模型具有较好的可靠性,有助于为钻井生产企业合理优化钻井液和固井水泥浆施工工艺提供理论支持。Abstract: The use of microbially induced carbonate precipitation (MICP) technology to improve the cementation quality of oil and gas well cementing has attracted more and more attention in recent years. At present, cementing slurry technology containing ore-forming microorganisms has been realized for shallow oil and gas wells of 3, 000 meters. In order to make the ore-forming microorganisms in the cement slurry filtrate effectively play the role of MICP at the two interfaces to improve the quality of the two-interface cementation, it is necessary to use the drilling fluid to carry the CaCl2 in the drilling process to pre-inject a certain amount of CaCl2 into the wellbore formation. Therefore, it is necessary to study the penetration law of CaCl2-containing drilling fluid in the wellbore formation, so as to reasonably control the CaCl2 injection volume and drilling cost. Based on this, this paper takes the commonly used environmentally friendly water-based polymer drilling fluid as the basic carrier, comprehensively considers the dynamic formation mechanism of mud cake at the well wall, the variation law of physical properties of the surrounding formation and the water-based polymer drilling with CaCl2. The factors such as liquid rheology and the combination of theoretical calculation and simulation experiment were used to establish a quantitative prediction model for the permeation and permeation distance of the drilling fluid containing CaCl2 water-based polymer in the wellbore formation. The calculation results of the prediction model are consistent with the simulation test results, and have good reliability, which helps to provide the oretical support for drilling production enterprises to rationally optimize drilling fluid and cement slurry construction technology.

-

表 1 CaCl2加量对水基聚合物钻井液塑性黏度的影响

Table 1. Effect of CaCl2 dosage on rheology of water-based polymer drilling fluid

钻井液编号 CaCl2加量wB/% 塑性黏度/(mPa·s) 1 0 15.28 2 5 12.87 3 10 12.72 4 15 17.15 5 20 22.15 6 25 24.81 7 30 27.00 8 40 32.27 9 50 42.53 表 2 含钻屑钻井液的基本性质

Table 2. Basic properties of drilling fluids containing drill cuttings

钻井液 w(CaCl2)/% 密度ρ/(g·cm-3) 塑性黏度μf/(mPa·s) 固相密度Cs/(g·cm-3) 泥饼孔隙度φc/% 泥饼密度ρc/(g·cm-3) 泥饼渗透率kc/m2 A 0 1.31 15.28 0.36 10.59 2.51 2.2×10-17 B 20 1.31 22.15 0.36 10.51 2.52 1.5×10-17 表 3 砂岩岩心物性参数及实验条件

Table 3. Physical parameters and experimental conditions of sandstone cores

岩心 岩心尺寸/mm 岩心孔隙度φ/% 岩心渗透率k0/m2 岩心密度ρ/(g·cm-3) 驱动压力pw/MPa 围压pd/MPa 地层压力pe/MPa ① Φ25.01×99.95 15.61 1.13×10-14 2.36 3 ② Φ24.94×99.97 15.56 1.15×10-14 2.35 2 4.5 1 ③ Φ25.02×99.98 19.34 5.91×10-14 2.32 3 -

[1] 宁伏龙, 方翔宇, 李彦龙, 等. 天然气水合物开采储层出砂研究进展与思考[J]. 地质科技通报, 2020, 39(1): 137-148. https://dzkjqb.cug.edu.cn/CN/abstract/abstract9934.shtmlNing F L, Fang X Y, Li Y L, et al. Research status and perspective on wellbore sand production from hydrate reservoirs[J]. Bulletin of Geological Science and Technology, 2020, 39(1): 137-148(in Chinese with English abstract). https://dzkjqb.cug.edu.cn/CN/abstract/abstract9934.shtml [2] 张翼, 方俊伟, 于培志, 等. 塔里木盆地顺北-区柯吐尔组失稳特征及钻井液技术研究[J]. 地质科技情报, 2019, 38(4): 281-286. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201904030.htmZhang Y, Fang J W, Yu P Z, et al. Instability characteristics and drilling fluid technology of the Ketur Formation in Shunbei District 1, Tarim Basin[J]. Geological Science and Technology Information, 2019, 38(4): 281-286(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201904030.htm [3] 刘天乐, 郑少军, 王韧, 等. 固井水泥浆侵入对近井壁水合物稳定的不利影响[J]. 石油学报, 2018, 39(8): 937-946. https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB201808009.htmLiu T L, Zheng S J, Wang R, et al. The adverse effect of cement slurry invasion on the stability of hydrates near the borehole wall[J]. Acta Petrolei Sinica, 2018, 39(8): 937-946(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB201808009.htm [4] Ramézani H, Akkal R, Cohaut N, et al. On the filtrate drilling fluid formation and near well-bore damage along the petroleum well[J]. Journal of Petroleum Science & Engineering, 2015, 135(6): 299-313. http://search.ebscohost.com/login.aspx?direct=true&db=aph&AN=111142537&site=ehost-live [5] Xu C, Kang Y, You Z, et al. Review on formation damage mechanisms and processes in shale gas reservoir: Known and to be known[J]. Journal of Natural Gas Science & Engineering, 2016, 49(36): 1208-1219. http://www.researchgate.net/profile/Chengyuan_Xu2/publication/301599043_Review_on_formation_damage_mechanisms_and_processes_in_shale_gas_reservoir_Known_and_to_be_known/links/58098d3908ae993dc050a4cc.pdf [6] Yuan H, Sarica C, Miska S. An experimental and analytical study of single-phase liquid flow in a horizontal well[J]. Journal of Energy Resources Technology, 1997, 119(1): 20-25. doi: 10.1115/1.2794217 [7] 王建华, 鄢捷年, 郑曼, 等. 钻井液固相和滤液侵入储层深度的预测模型[J]. 石油学报, 2009, 30(6): 923-926. doi: 10.3321/j.issn:0253-2697.2009.06.022Wang J H, Yan J N, Zheng M, et al. Drilling fluid solid phase and filtrate invade the reservoir depth prediction model[J]. Acta Petrolei Sinica, 2009, 30(6): 923-926(in Chinese with English abstract). doi: 10.3321/j.issn:0253-2697.2009.06.022 [8] 周福建, 宋广顺. 用现场资料预测钻井液损害储层深度[J]. 钻井液与完井液, 2000, 17(4): 8-10. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJYW200004002.htmZhou F J, Song G S. Using field data to predict the depth of reservoir damage by drilling fluid[J]. Drilling Fluids and Completion Fluids, 2000, 17(4): 8-10(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-ZJYW200004002.htm [9] Civan F. Practical model for compressive cake filtration including fine particle invasion[J]. AIChE Journal, 1998, 44(11): 2388-2398. doi: 10.1002/aic.690441107 [10] Parn-Anurak S, Engler T W. Modeling of fluid filtration and near wellbore damiage along a horizontal well[J]. Journal of Petroleum Science & Engineering, 2005, 46(3): 149-160. http://www.onacademic.com/detail/journal_1000034030418710_069e.html [11] Liu X H, Civan F. Formation damage and filter cake buildup in laboratory core tests: Modeling and model-assisted analysis[J]. SPE, 2006: 25215. http://www.onacademic.com/detail/journal_1000039068883410_3408.html [12] Martins A L, Waldmann A T A, Aragao A F L, et al. Predicting and monitoring fluid invasion in exploratory drilling[J]. SPE, 2004: 86497. http://www.zhangqiaokeyan.com/academic-journal-foreign_other_thesis/020416846598.html [13] Waldmann A T A, Leal R A F, Pires I J, et al. Minimizing drilling-fluid invasion in coring operations[C]//Anon. EuropeanFormation Damage Conference. [S. l. ]: [s. n. ], 2007. [14] Pang S, Sharma M. A model for predictin injectivity decline in water-injection wells[C]//Anon. SPE formation evaluation. [S. l. ]: SPE, 1997, 28489: 194-201. [15] Hussain F, Zeinijahromi A, Bedrikovetsky P, et al. An experimental study of improved oil recovery through fines-assisted waterflooding[J]. Journal of Petroleum Science & Engineering, 2013, 109: 187-197. http://www.onacademic.com/detail/journal_1000035969702710_d6da.html [16] Windarto W, Gunawan A Y, Sukarno P, et al. Modelling of formation damage due to mud filtrate invasion in a radial flow system[J]. Journal of Petroleum Science & Engineering, 2012, 100(6): 99-105. http://www.onacademic.com/detail/journal_1000036499966410_96d9.html [17] 鄢捷年. 钻井液工艺学[M]. 山东东营: 石油大学出版社, 2013.Yan J N. Drilling fluid technology[M]. Dongying Shandong: University of Petroleum Press, 2013(in Chinese). [18] 乌效鸣, 蔡记华, 胡郁乐. 钻井液与岩土工程浆材[M]. 武汉: 中国地质大学出版社, 2014.Wu X M, Cai J H, Hu Y L. Drilling fluid and geotechnical engineering grout[M]. Wuhan: China University of Geosciences Press, 2014(in Chinese). [19] Bharat B P. Drilling fluid additive and process therewith: US, 6124245[P]. 1998-10-07. [20] James E, Michael A. Shale stabilizing drilling fluids comprising calcium chloride and low molecular weight low charge cationicpolycrylamide copolymers: US, 6355600[P]. 1999-10-01. [21] 方俊伟, 苏晓明, 熊汉桥, 等. 塔中区块成膜封缝堵气钻井液体系[J]. 地质科技情报, 2019, 38(2): 297-302. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201902036.htmFang J W, Su X M, Xiong H Q, et al. Film-forming, seam-sealing and gas-blocking drilling fluid system in Tazhong block[J]. Geological Science and Technology Information, 2019, 38(2): 297-302(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201902036.htm -

下载:

下载: