Numerical simulation of working characteristics of energy pile group under thermo-mechanical coupling

-

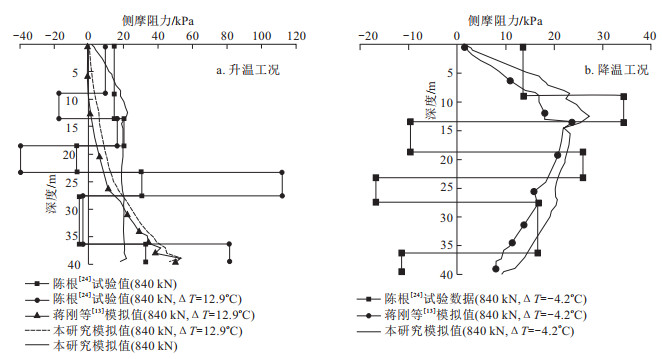

摘要: 为研究能源群桩工作特性,基于Abaqus有限元模拟,将换热稳定阶段的平均温度赋予桩体进行稳态热-力耦合计算,提出了能源群桩承载特性的简化分析方法,并通过与现场数据的对比分析,验证了该研究方法的可行性。结合算例,进一步利用该方法对纯力学荷载和热-力耦合作用下的能源群桩的承载特性进行了分析。结果表明:①群桩基础中能源桩分散对称分布的不均匀沉降要明显小于集中分布,而且分布形式对桩基结构响应特征影响较大;②桩基等刚度下,增大桩径和减小桩间距,群桩倾斜控制效果较好。研究成果可以为能源群桩的工程应用提供一定的参考。Abstract: In order to study the working characteristics of energy pile groups, based on the Abaqus finite element simulation, assigns the average temperature of the heat transfer stable stage to the pile body for steady-state thermo-mechanical coupling calculation, and proposes a simplified analysis method for the bearing characteristics of energy pile groups.The reliability of this research method is verified through the comparative analysis with field data.Combined with an example, this method is used to analyze the bearing characteristics of energy group piles under the action of pure mechanical load and thermal coupling.The results show that the non-uniform settlement of the distributed symmetrical arrangement of energy piles in the pile group foundation is significantly less than that of the centralized arrangement, and the layout has a great influence on the response characteristics of the pile foundation structure.Under the condition of equal stiffness of pile foundation, the control effect of pile group tilt is better by increasing pile diameter and decreasing pile spacing.The research results of this paper can provide some reference value for the engineering application of energy pile group.

-

Key words:

- energy pile group /

- numerical simulation /

- thermo-mechanical coupling /

- differential settlement /

- Abaqus

-

表 1 桩-土力学及热物性参数

Table 1. Pile-soil mechanics and thermal property parameters

桩身密度/

(kg·m-3)桩体弹性模量/GPa 桩体泊松比 桩体热膨胀系数/

(m· ℃-1)桩体导热系数/(W·

m-1·℃-1)桩体比热容/

(J·kg-1·

℃-1)土体综合导热系数/(W·

m-1·℃-1)土体综合比热容/(J·kg-1·

℃-1)土体综合热膨胀系数/

(m·℃-1)2 500 30 0.2 1.0×10-5 2.3 960 1.8 1 500 5.0×10-6 表 2 土层分布及物理力学参数

Table 2. Soil layer distribution and physical and mechanical parameters

土层编号 土层 厚度/m 密度/(kg·m-3) 黏聚力/kPa 内摩擦角/(°) 泊松比 弹性模量 桩土摩擦系数 ①-1 素填土 3.0 1 800 9 11.6 0.35 28 0.2 ① 表土 2.0 1 800 9 11.6 0.35 28 0.2 ② 粉质黏土 1.5 1 830 22 12.8 0.35 25 0.2 ③ 淤泥质粉质黏土 2.0 1 830 13 10.0 0.40 15 0.2 ④ 粉质黏土 5.0 1 940 42 15.0 0.35 80 0.2 ⑤-1 粉土夹粉砂 6.0 1 840 8 25.1 0.30 100 0.3 ⑤-2 粉砂夹粉土 6.0 1 860 6 27.1 0.30 140 0.3 ⑥ 粉土 2.5 1 810 9 22.1 0.30 120 0.3 ⑦ 粉土 12.0 1 840 8 25.2 0.30 200 0.3 表 3 不同能源桩布设形式的倾斜

Table 3. Tilt of different energy pile layout forms

换热工况 单桩 临近双桩 对角双桩 加热 倾斜/% 1.20 0.823 0.872 降温 0.81 0.984 0.876 表 4 不同桩间距和承台厚度情况下的倾斜

Table 4. Tilting under different pile spacing and pile cap thickness

编号 桩长/m 桩径/m 桩间距/m 承台厚度/m 倾斜/‰ 1 30 0.3 2.4 0.5 0.44 2 30 0.3 3.0 0.5 0.93 3 30 0.4 3.0 0.5 0.95 4 30 0.4 3.0 0.6 0.67 5 30 0.4 3.0 0.8 0.55 6 30 0.4 3.0 1.0 0.53 7 30 0.4 3.0 1.5 0.51 -

[1] Laloui L, Nuth M, Vulliet L. Experimental and numerical investigations of the behaviour of a heat exchanger pile[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2005, 30(8): 763-781. doi: 10.1002/nag.499/pdf [2] Mc Cartney J S, Murphy K D. Strain distributions in full-scale energy foundations[J]. The Journal of the Deep Foundations Institute, 2012, 6(2): 26-38. doi: 10.1179/dfi.2012.008 [3] 桂树强, 程晓辉. 能源桩换热过程中结构响应原位试验研究[J]. 岩土工程学报, 2014, 36(6): 1087-1094. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201406018.htmGui S Q, Cheng X H. In-situ tests on structural responses of energy piles during heat exchanging process[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(6): 1087-1094(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201406018.htm [4] Stewart M A, Mccartney J S. Centrifuge modeling of soil-structure interaction in energy foundations[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2014, 140(4): 04013044. doi: 10.1061/(ASCE)GT.1943-5606.0001061 [5] Ng C W W, Shi C, Gunawan A, et al. Centrifuge modelling of heating effects on energy pile performance in[J]. Canadian Geotechnical Journal, 2015, 52(8): 1045-1057. doi: 10.1139/cgj-2014-0301 [6] 刘汉龙, 王成龙, 孔纲强, 等. 不同压实度下能量桩的热力学效应[J]. 中国科技论文, 2016, 11(13): 1511-1515. doi: 10.3969/j.issn.2095-2783.2016.13.016Liu H L, Wang C L, Kong G Q, et al. Thermal-mechanical characteristics of energy pile under different degree of compaction[J]. China Science Paper, 2016, 11(13): 1511-1515(in Chinese with English abstract). doi: 10.3969/j.issn.2095-2783.2016.13.016 [7] 刘汉龙, 吴迪, 孔纲强, 等. 预埋与绑扎埋管形式能量桩传热特性研究[J]. 岩土力学, 2017, 38(2): 333-340. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201702005.htmLiu H L, Wu D, Kong G Q, et al. Thermal response of energy piles with embedded tube and tied tube[J]. Rock and Soil Mechanics, 2017, 38(2): 333-340(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201702005.htm [8] 孔纲强, 王成龙, 刘汉龙, 等. 多次温度循环对能量桩桩顶位移影响分析[J]. 岩土力学, 2017, 38(4): 1-7. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201704006.htmKong G Q, Liu H L, Wang C L, et al. Analysis of pile head displacement of energy pile under repeated temperature cycling[J]. Rock and Soil Mechanics, 2017, 38(4): 1-7(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201704006.htm [9] Knellwolf C, Péron H, Laloui L. Geotechnical analysis of heat exchanger piles[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2011, 137(10): 890-902. doi: 10.1061/(ASCE)GT.1943-5606.0000513 [10] 费康, 戴迪, 洪伟. 能量桩单桩工作特性简化分析方法[J]. 岩土力学, 2019, 40(1): 70-80, 90. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201901004.htmFei K, Dai D, Hong W. A simplified method for working performance analysis of single energy piles[J]. Rock and Soil Mechanics, 2019, 40(1): 70-80, 90(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201901004.htm [11] 罗喆, 胡彪. 基于热力荷载传递原理的能量桩长期响应研究[J]. 防灾减灾工程学报, 2019, 39(4): 549-555, 563. https://www.cnki.com.cn/Article/CJFDTOTAL-DZXK201904002.htmLuo Z, Hu B. Study on long-term response of energy pile based on thermal load transfer principle[J]. Journal of Disaster Prevention and Mitigation Engineering, 2019, 39(4): 549-555, 563(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZXK201904002.htm [12] 董龙龙, 吴文兵, 梁荣柱, 等. 基于指数模型的能源桩长期响应研究[J]. 岩石力学与工程学报, 2021, 40(3): 629-639. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202103017.htmDong L L, Wu W B, Liang R Z, et al. Study on long-term response of energy pile based on exponential model[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(3): 629-639(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX202103017.htm [13] 蒋刚, 李仁飞, 王昊, 等. 摩擦型能源桩热-力耦合全过程承载性能分析[J]. 岩石力学与工程学报, 2019, 38(12): 2525-2534. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201912012.htmJiang G, Li R F, Wang H, et al. Numerical analysis of the bearing capacity of floating energy piles during the full process of thermal-mechanical coupling[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(12): 2525-2534(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201912012.htm [14] Fang J, Kong G, Meng Y, et al. Thermomechanical behavior of energy piles and interactions within energy pile-raft foundations[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2020, 146(9): 04020079. doi: 10.1061/(ASCE)GT.1943-5606.0002333 [15] Ng C, Ma Q J. Energy pile group subjected to non-symmetrical cyclic thermal loading in centrifuge[J]. Géotechnique Letters, 2019, 9(2): 1-17. http://www.researchgate.net/publication/334272138_Energy_pile_group_subjected_to_non-symmetrical_cyclic_thermal_loading_in_centrifuge [16] Jeong S, Lim H, Lee J K, et al. Thermally induced mechanical response of energy piles in axially loaded pile groups[J]. Applied Thermal Engineering, 2014, 71(1): 608-615. doi: 10.1016/j.applthermaleng.2014.07.007 [17] Dupray F, Laloui L, Kazangba A. Numerical analysis of seasonal heat storage in an energy pile foundation[J]. Computers and Geotechnics, 2014, 55: 67-77. doi: 10.1016/j.compgeo.2013.08.004 [18] Saggu R, Chakraborty T. Thermomechanical response of geothermal energy pile groups in sand[J]. International Journal of Geomechanics, ASCE, 2016, 16(4): 04015100. doi: 10.1061/(ASCE)GM.1943-5622.0000567 [19] Salciarini D, Ronchi F, Cattoni E, et al. Thermo mechanical effects induced by energy piles operation in a small piled raft[J]. International Journal of Geomechanics, ASCE, 2015, 15(2): 04014042. doi: 10.1061/(ASCE)GM.1943-5622.0000375 [20] Suryatriyastuti M E, Burlon S, Mroueh H. On the understanding of cyclic interaction mechanisms in an energy pile group[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2016, 40(1): 3-24. doi: 10.1002/nag.2382 [21] Peng H, Kong G, Liu H, et al. Thermo mechanical behaviour of floating energy pile groups in sand[J]. Journal of Zhejiang University: Science A, 2018, 19(8): 638-649. doi: 10.1631/jzus.A1700460 [22] Murphy K D, Mccartney J S, Henry K S. Evaluation of thermo-mechanical and thermal behavior of full-scale energy foundations[J]. Acta Geotechnica, 2013, 10(2): 179-195. doi: 10.1007/s11440-013-0298-4 [23] 费康, 朱志慧, 石雨恒, 等. 能量桩群桩工作特性简化分析方法研究[J]. 岩土力学, 2020, 41(12): 3889-3898. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202012008.htmFei K, Zhu Z H, Shi Y H, et al. A simplified method for geotechnical analysis of energy pile groups[J]. Rock and Soil Mechanics, 2020, 41(12): 3889-3898(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202012008.htm [24] 陈根. 长桩型能源桩热-力耦合承载性能的现场测试与数值分析[D]. 南京: 南京工业大学, 2017.Chen G. Field test and numerical analysis of thermal-mechanical coupling bearing capacity of long pile type energy pile[D]. Nanjing: Nanjing Tech University, 2017(in Chinese with English abstract). [25] Batinia N, Alessandro F R L, Conti P, et al. Energy and geotechnical behaviour of energy piles for different design solutions[J]. Applied Thermal Engineering, 2015, 86: 199-213. doi: 10.1002/nag.2341 [26] 龚晓南, 陈明中. 桩筏基础设计方案优化若干问题[J]. 土木工程学报, 2001, 34(4): 107-110. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC200104017.htmGong X N, Chen M Z. Some issues on the optimum design for a piled raft foundation[J]. Chinese Journal of Civil Engineering, 2001, 34(4): 107-110(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC200104017.htm [27] 王忠凯, 徐光黎. 盾构施工对既有建(构)筑地基承载力影响及加固土体稳定性分析[J]. 地质科技通报, 2020, 39(4): 109-116. doi: 10.19509/j.cnki.dzkq.2020.0414Wang Z K, Xu G L. Effect of shield tunneling construction on bearing capacity of existing buildings and stability analysis of reinforced soil[J]. Bulletin of Geological Science and Technology, 2020, 39(4): 109-116(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2020.0414 [28] 江强强, 焦玉勇, 骆进, 等. 能源桩传热与承载特性研究现状及展望[J]. 岩土力学, 2019, 40(9): 3351-3362, 3372. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201909008.htmJiang Q Q, Jiao Y Y, Luo J, et al. Review and prospect on heat transfer and bearing performance of energy piles[J]. Rock and Soil Mechanics, 2019, 40(9): 3351-3362, 3372(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201909008.htm [29] 陈鑫, 向先超, 刘凯, 等. 小桩距下的抗滑桩后滑坡推力分布规律分析[J]. 地质科技情报, 2019, 38(6): 157-164. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201906019.htmChen X, Xiang X C, Liu K, et al. Thrust distribution law of anti-slide pile under small pile spacing[J]. Geological Science and Technology Information, 2019, 38(6): 157-164(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201906019.htm -

下载:

下载: