Granule structure influences on force chain development in the slag medium

-

摘要:

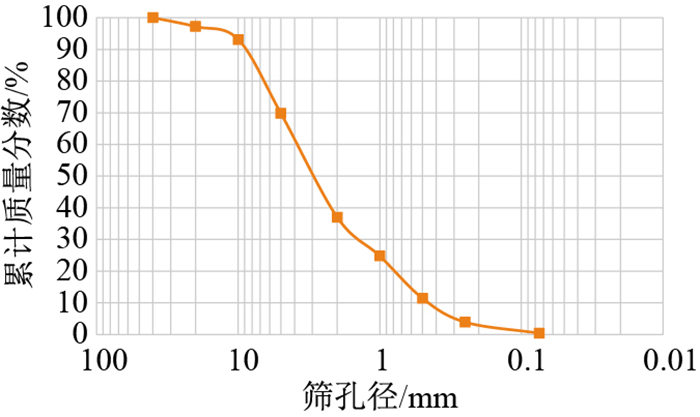

矿业活动产生的渣体是不规则颗粒介质, 具有级配复杂、结构不稳定的特征, 颗粒间通过力链传递应力。以典型铜矿渣为研究对象, 借助CT扫描技术获得矿渣的颗粒结构形态, 通过开展不同粗颗粒含量的平面压缩试验和数值模拟试验, 得到宏观力学变形曲线及力链发展过程和颗粒结构变化, 讨论颗粒结构和力链发展协同作用对宏观力学性质的影响机制, 以及颗粒介质材料压缩发展规律。结果表明: 矿渣类颗粒介质材料的力链发展方向与压力方向一致; 矿渣宏观抗压性能随>5 mm粗颗粒含量的增加先增后减, 在最优粗细颗粒配比50%处达到最大抗压强度; 颗粒结构和力链间软硬结构存在显著的协同演化; 压缩过程中内部存在快速压密、颗粒破碎和稳定压缩3个阶段。在矿渣堆填过程中, 除控制其粗颗粒在最优级配外, 保持均匀填筑和合理的压实使其进入稳定压缩阶段也非常重要。

Abstract:The slag dumps formed by mining activities are irregular granular media. Their particle size gradations are complex and granule structures are unstable.The stress between particles is transferred through the dependently unstable force chain. Taking the typical copper slag as the study object, its granule structure was investigated using CT scanning technology. According to plane compression and corresponding numerical simulation tests on coarse particles of different mass fraction contents, stress-straincurves, force chain evolutions and granule structure changes were obtained.Further, the synergistic effect between granule structure and force chain evolutionon macro-mechanics was discussed. Meanwhile, the compression law of granular material was revealed. The results show that the direction of force chain evolution direction inslag granular materialis consistent with the direction of pressure. The macro-compressive strength of slag increases first and then decreases with increasing coarse particle (>5 mm) mass fraction content and reaches the maximum compressive strength at the optimal coarse particle ratio of 50%. The granule structure and the soft-hard structure inforce chains have a significant synergistic effect. The granule structure change in slag granular material will experience three stages during compression process: the rapid compaction stage, particle crushing stage and stable compression stage. In the process of slag landfill, it is important to keep uniform filling and reasonable compaction to make it enter the stable compression stage, as well as controlling the optimal grading of coarse particles.

-

Key words:

- slag /

- granular material /

- granule structure /

- force chain /

- plane compression test

-

表 1 铜矿渣的级配参数表

Table 1. Gradation parameter of copper slag

名称 d10/mm d30/mm d60/mm Cu=d60/d10 Cc=d302/(d10d60) 平均粒径d50/mm 粗颗粒w5/% 铜矿渣颗粒级配 0.47 1.27 3.84 8.17 0.89 2.98 30.15 注:定义粒径>5 mm的颗粒为粗颗粒,粗颗粒质量分数用w5表示;d10为小于该粒径的土颗粒的质量占土颗粒总质量的10%,也称有效粒径;d30为小于该粒径的土颗粒的质量占土颗粒总质量的30%,也称连续粒径;d60为小于该粒径的土颗粒的质量占土颗粒总质量的60%,也称控制粒径 表 2 铜矿渣6组优势外形轮廓几何参数统计表

Table 2. Statistical table of geometric parameters of six groups of dominant profiles of copper slags

分类 1 2 3 4 5 6 优势外轮廓

球形度S 0.29 0.60 0.65 0.52 0.69 0.33 长宽比F 5.96 3.31 3.16 3.85 3.63 5.62 圆形度R 1.22 1.10 1.02 1.07 1.08 1.05 表 3 铜矿渣大型压缩试验参数反演标定

Table 3. Parameter inversion calibration table for the large-scale compression test of copper slag

参数类型 标定值 颗粒密度ρ/(kg·m-3) 2 608 接触颗粒间弹性模量Ec/Pa 2×107 法向切向刚度比k 1.05 接触摩擦系数μ 0.3 平行黏结弹性模量Ep/Pa 6.5×107 平行黏结刚度比kp 1.05 平行黏结抗拉强度σc/Pa 0.9×107 平行黏结内聚力c/Pa 4.5×107 -

[1] Nyssen J, Vermeersch D. Slope aspect affects geomorphic dynamics of coal mining spoil heaps in Belgium[J]. Geomorphology, 2010, 123(1/2): 109-121. [2] Song Y S, Cho Y C, Hong S. Analyses on variations in the unsaturated characteristics of a mine waste-dump slope during rainfall[J]. Environmental Earth Sciences, 2016, 75(14): 1106-1118. doi: 10.1007/s12665-016-5877-x [3] Yin Y P, Li B, Wang W P, et al. Mechanism of the December 2015 catastrophic landslide at the Shenzhen landfill and controlling geotechnical risks of urbanization[J]. Engineering, 2016, 2(2): 176-216. [4] 唐朝晖, 柴波, 刘忠臣, 等. 填土边坡稳定性的可靠度分析[J]. 地球科学: 中国地质大学学报, 2013, 38(3): 616-624.Tang Z H, Chai B, Liu Z C, et al. Reliability analysis of stability of fill slope[J]. Earth Sciences: Journal of China University of Geosciences, 2013, 38(3): 616-624(in Chinese with English abstract). [5] 李宏达, 简文彬, 蔡泽宏, 等. 福建某排土场边坡降雨作用下渗流稳定时变分析[J]. 路基工程, 2016, 49(4): 33-36. https://www.cnki.com.cn/Article/CJFDTOTAL-LJGC201604011.htmLi H D, Jian W B, Cai Z H, et al. Time-dependent analysis on seepage stability of a refuse-dump slope under in Fujian[J]. Subgrade Engineering, 2016, 49(4): 33-36(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-LJGC201604011.htm [6] Ebrahimian B, Noorzad A, Alsaleh M I. Modeling shear localization along granular soil-structure interfaces using elasto-plastic Cosserat continuum[J]. International Journal of Solids & Structures, 2012, 49(2): 257-278. [7] Marsal R J. Large scale testing of coarse grained materials[J]. Journal of the Soil Mechanics and Foundations Division, ASCE, 1967, 93(2): 27-43. doi: 10.1061/JSFEAQ.0000958 [8] 梁军, 刘汉龙, 高玉峰. 堆石蠕变机理分析与颗粒破碎特性研究[J]. 岩土力学, 2003, 24(3): 479-483. doi: 10.3969/j.issn.1000-7598.2003.03.032Liang J, Liu H L, Gao Y F. Creep mechanism and breakage of rockfill[J]. Rock and Soil Mechanics, 2003, 24(3): 479- 483(in Chinese with English abstract). doi: 10.3969/j.issn.1000-7598.2003.03.032 [9] Zhu H, Nicot F, Darve F. Meso-structure organization in two-dimensional granular materials along biaxial loadingpath[J]. International Journal of Solids & Structures, 2016, 96(1): 25-37. [10] Caicedo B, Ocampo M, Vallejo L. Modelling comminution of granular materials using a linear packing model and Markovian processes[J]. Computers and Geotechnics, 2016, 80(12): 383-396. [11] Salim W, Indrararna B. A new elasto-plastic constitutive model for granular aggregates incorporating particle breakage[J]. Canadian Geotechnical Journal, 2004, 41(4): 657-671. doi: 10.1139/t04-025 [12] 高政国, Shen H H. 基于颗粒组构特性的散体材料本构模型研究[J]. 岩土力学, 2009, 30(增刊1): 93-98. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2009S1019.htmGao Z G, Shen H H. A study of constitutive model for granular materials based on characters of discrete particles arranged[J]. Rock and Soil Mechanics 2009, 30(S1): 93-98 (in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2009S1019.htm [13] 杨光, 张丙印, 于玉贞, 等. 不同应力路径下粗粒料的颗粒破碎试验研究[J]. 水利学报, 2010, 41(3): 338-342. https://www.cnki.com.cn/Article/CJFDTOTAL-SLXB201003013.htmYang G, Zhang B Y, Yu Y Z, et al. An experimental study on particle breakage of coarse-grainedmaterials under various stress paths[J]. Journal of Water Conservancy, 2010, 41(3): 338-342 (in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SLXB201003013.htm [14] Estrada N, Taboada A. Yield surfaces and plastic potentials of cemented granular materials from discrete elementsimulations[J]. Computers and Geotechnics, 2013, 49(4): 62-69. [15] Kim B S, Park S W, Kato S. DEM simulation of collapse behaviours of unsaturated granular materials under general stress states[J]. Computers and Geotechnics, 2012, 42(5): 52-61. [16] Tang H, Dong Y, Chu X, et al. The influence of particle rolling and imperfections on the formation of shear bands in granular material[J]. Granular Matter, 2016, 18(1): 12. doi: 10.1007/s10035-016-0607-3 [17] 柴波, 陶阳阳, 杜娟, 等. 基于Hoek-Brown准则的节理岩体能量参数估算[J]. 地质科技通报, 2020, 39(1): 78-85. doi: 10.19509/j.cnki.dzkq.2020.0109Chai B, Tao Y Y, Du J, et al. Energetics parameter estimation of jointed rock mass based on Hoek-Brown failure criterion[J]. Bulletin of Geological Science and Technology, 2020, 39(1): 78-85 (in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2020.0109 [18] 林成远, 唐辉明, 汪丁建, 等. 块石定向性特征对土-石混合体强度影响的数值模拟[J]. 地质科技通报, 2020, 39(5): 38-46. doi: 10.19509/j.cnki.dzkq.2020.0519Li C Y, Tang H M, Wang D J, et al. Influence on the strength of soil-rock mixture made by the rock block orientation features based on numerical experiment[J]. Bulletin of Geological Science and Technology, 2020, 39(5): 38-46(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2020.0519 [19] 贾学明, 柴贺军, 郑颖人. 土石混合料大型直剪试验的颗粒离散元细观力学模拟研究[J]. 岩土力学, 2010, 31(9): 2695-2703. doi: 10.3969/j.issn.1000-7598.2010.09.002Jia X M, Chai H J, Zheng Y R. Mesomechanics research of large direct shear test of soil and aggregate mixture with particle flow code simulation[J]. Rock and Soil Mechanics, 2010, 31(9): 2695-2703(in Chinese with English abstract). doi: 10.3969/j.issn.1000-7598.2010.09.002 [20] 肖柏林, 杨志强, 陈得信, 等. 充填骨料颗粒形态参数定量评价方法[J]. 天津大学学报: 自然科学与工程技术版, 2019, 52(5): 545-553. https://www.cnki.com.cn/Article/CJFDTOTAL-TJDX201905013.htmXiao B L, Yang Z Q, Chen D X, et al. Evaluation of the quantifying methods for shape characteristics of filling aggregate[J]. Journal of Tianjin University: Natural Science and Engineering Technology Edition, 2019, 52(5): 545-553 (in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-TJDX201905013.htm -

下载:

下载: