Experiment research of the influence of different cooling times on the drillability of high-temperature granite

-

摘要:

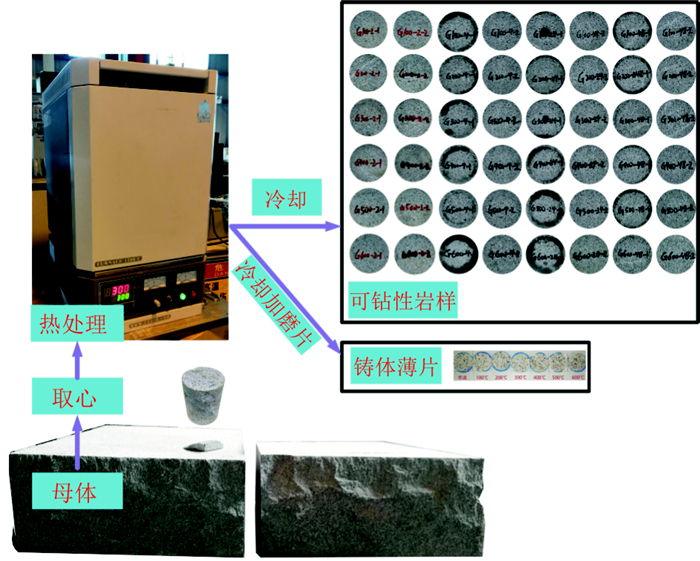

为了研究高温后花岗岩的可钻性和微观损伤变化, 同时也为了研究高温后不同冷却时间对可钻性的影响, 对高温热处理后的花岗岩冷却不同时间(2, 4, 24, 48 h), 通过可钻性实验和铸体薄片鉴定, 得到高温对花岗岩可钻性的影响规律和影响机理, 同时也得到不同冷却时间对花岗岩可钻性的影响。研究结果表明, 花岗岩在热处理不超过500℃和自然冷却2 h的约束下始终保持一个较高的可钻性级值, 在冷却4, 24, 48 h后, 高温对可钻性的影响表现为3个阶段(第一次劣化阶段、强化阶段、第二次劣化阶段)。微裂纹产生的位置及数量影响着岩石抵抗破碎的难易程度, 400℃热处理后花岗岩内部微裂纹开始显著增加, 当石英颗粒内部产生大量微裂纹时, 花岗岩的可钻性显著降低。100℃热处理后同时冷却不超过4 h会显著影响花岗岩的可钻性, 200~400℃热处理后, 花岗岩的可钻性级值会随着冷却时间(4~48 h)的继续增加显著增加, 500℃对花岗岩产生的损伤是不可恢复的, 600℃已经完全使花岗岩劣化。弄清高温和冷却时间对花岗岩可钻性的影响, 可以为干热岩资源的高效开采提供基础的理论支撑。

Abstract:To study the drillability and microscopic damage changes of granite after high temperature exposure and to study the influence of different cooling times on drillability after high temperature exposure, granite for high-temperature heat treatment was cooled by different times (2 h, 4 h, 24 h, and 48 h). Through the drillability experiment and the cast thin identification of the processed rock samples, the influence law and mechanism of high temperature on the drillability of granite were obtained, and the influence of different cooling times on the granite drillability was also investigated. The research results show that granite always maintains a high drillability index under the constraints of heat treatment not exceeding 500℃ and natural cooling for 2 h. After cooling 4 h, 24 h, and 48 h, the impact of high temperature on drillability shows three stages (First degradation stage, strengthening stage, second degradation stage). The location and number of microcracks affect the difficulty of rock resistance to crushing. After 400℃ heat treatment, the internal microcracks of the granite begin to increase significantly. When the microcracks generate a large number of microcracks inside the quartz particles, the drillability of the granite is significantly reduced. After heat treatment at 100℃, cooling for no more than 4 h at the same time will significantly affect the drillability of granite. After heat treatment at 200-400℃, the drillability index of granite will increase significantly as the cooling time (4-48 h) continues to increase. The damage caused by 500℃ to granite is irreversible, and 600℃ has completely degraded the granite. Understanding the influence of high temperature and cooling time on the drillability of granite can provide basic theoretical support for the efficient exploitation of hot dry rock resources.

-

Key words:

- cooling time /

- high temperature /

- granite /

- drillability

-

表 1 不同冷却时间和不同热处理温度下花岗岩可钻性级值

Table 1. Drillability index of granite under different cooling times and different heat treatment temperatures

温度/

℃冷却时间/h 2 4 24 48 100 5.66,5.91 4.33,4.25 4.10,3.37 4.08,4.16 200 5.73,5.14 5.68,5.80 6.11,6.19 6.49,6.53 300 5.65,6.38 6.73,6.76 7.45,7.89 7.21,7.64 400 6.58,6.26 4.93,4.96 5.28,5.15 6.13,6.13 500 6.03,6.18 4.79,4.62 3.57,3.98 3.70,3.38 600 2.08,4.62 岩石破坏 1.01,2.60 2.16,2.09 注:2次测试结果 -

[1] 刘德民, 张昌生, 孙明行, 等. 干热岩勘查评价指标与形成条件[J]. 地质科技通报, 2021, 40(3): 1-11 doi: 10.19509/j.cnki.dzkq.2021.0316Liu D M, Zhang C S, Sun M X, et al. Evaluation indexes and formation conditions of hot dry rock exploration[J]. Bulletin of Geological Science and Technology, 2021, 40(3): 1-11(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2021.0316 [2] 王贵玲, 张薇, 梁继运, 等. 中国地热资源潜力评价[J]. 地球学报, 2017, 38(4): 449-450. https://www.cnki.com.cn/Article/CJFDTOTAL-DQXB201704002.htmWang G L, Zhang W, Liang J Y, et al. Evaluation of geothermal resources potential in China[J]. Acta Geoscientica Sinica, 2017, 38(4): 449-450(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DQXB201704002.htm [3] 朱喜, 张庆莲, 刘彦广. 基于热储法的鲁西平原地热资源评价[J]. 地质科技情报, 2016, 35(4): 172-177. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201604027.htmZhu X, Zhang Q L, Liu Y G. Evaluation of the geothermal resources in the plain of West Shandong Province[J]. Geological Science and Technology Information, 2016, 35(4): 172-177(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201604027.htm [4] 窦斌, 高辉, 周刚, 等. 我国发展增强型地热开采技术所面临的机遇与挑战[J]. 地质科技情报, 2014, 33(5): 208-210. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201405032.htmDou B, Gao H, Zhou G, et al. Opportunities and challenges of developing enhance geothermal system technology in China[J]. Geological Science and Technology Information, 2014, 33(5): 208-210(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201405032.htm [5] 王贵玲, 张发旺, 刘志明. 国内外地热能开发利用现状及前景分析[J]. 地球学报, 2000, 21(2): 134-139. doi: 10.3321/j.issn:1006-3021.2000.02.004Wang G L, Zhang F W, Liu Z M. An analysis of present situation and prospects of geothermal energy development and utilization in the world[J]. Acta Geoscientica Sinica, 2000, 21(2): 134-139(in Chinese with English abstract). doi: 10.3321/j.issn:1006-3021.2000.02.004 [6] 赵静, 王旭升, 万力. 深层地热资源评价中的回收率问题[J]. 地质科技情报, 2008, 27(6): 89-92. doi: 10.3969/j.issn.1000-7849.2008.06.017Zhao J, Wang X S, Wang L. The recovery rate in assessment of deep geothermal resources[J]. Geological Science and Technology Information, 2008, 27(6): 89-92(in Chinese with English abstract). doi: 10.3969/j.issn.1000-7849.2008.06.017 [7] 王贵玲. 我国地热资源勘查评价战略研究[J]. 地热能, 2010(6): 15-20. https://cpfd.cnki.com.cn/Article/CPFDTOTAL-IGNH201010001010.htmWang G L. Study on exploration and evaluation strategy of geothermal resources in China[J]. Geothermal Energy, 2010(6): 15-20(in Chinese with English abstract). https://cpfd.cnki.com.cn/Article/CPFDTOTAL-IGNH201010001010.htm [8] 王贵玲, 刘彦广, 朱喜, 等. 中国地热资源现状及发展趋势[J]. 地学前缘, 2020, 27(1): 1-9. https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY202001002.htmWang G L, Liu Y G, Zhu X, et al. The status and development trend of geothermal resources in China[J]. Earth Science Frontiers, 2020, 27(1): 1-9(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY202001002.htm [9] 方新宇, 许金余, 刘石, 等. 高温后花岗岩的劈裂试验及热损伤特性研究[J]. 岩石力学与工程学报, 2016, 35(增刊1): 2687-2694. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2016S1012.htmFang X Y, Xu J Y, Liu S, et al. Research on splitting-tensile tests and thermal damage of granite under post-high temperature[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(S1): 2687-2694(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2016S1012.htm [10] Qin Y, Jing H W, Liu R C, et al. Pore characteristics and nonlinear flow behaviors of granite exposed to high temperature[J]. Bulletin of Engineering Geology and the Environment, 2020, 79(3): 1239-1257. doi: 10.1007/s10064-019-01628-6 [11] Qin Y, Tian H, Xu N X, et al. Physical and mechanical properties of granite after high-temperature treatment[J]. Rock Mechanics and Rock Engineering, 2020, 53(1): 305-322. doi: 10.1007/s00603-019-01919-0 [12] 阴伟涛, 赵阳升, 冯子军. 高温三轴应力下粗、细粒花岗岩力学特性研究[J]. 太原理工大学学报, 2020, 51(5): 627-633. https://www.cnki.com.cn/Article/CJFDTOTAL-TYGY202005002.htmYin W T, Zhan Y S, Feng Z J. Study on the mechanical properties of coarse-grained and fine-grained granite under high temperature triaxial stress[J]. Journal of Taiyuan University of Technology, 2020, 51(5): 627-633(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-TYGY202005002.htm [13] 苏国韶, 陈智勇, 尹宏雪, 等. 高温后花岗岩岩爆的真三轴试验研究[J]. 岩土工程学报, 2016, 38(9): 1586-1594. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201609006.htmSu G S, Chen Z Y, Yin H X, et al. True triaxial tests on rockburst of granite after high temperatures[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(9): 1586-1594(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201609006.htm [14] 马兵, 陈虹宇. 高温后花岗岩声发射特征与损伤演化规律[J]. 矿业研究与开发, 2020, 40(1): 22-27. https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK202001005.htmMa B, Chen H Y. Acoustic emission characteristics and damage evolution of granite after elevated temperature[J]. Mining Research and Development, 2020, 40(1): 22-27(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK202001005.htm [15] 周波, 汪海阁, 张富成, 等. 温度压力对岩石可钻性和破岩效率影响实验[J]. 石油钻采工艺, 2020, 42(5): 547-552. https://www.cnki.com.cn/Article/CJFDTOTAL-SYZC202005003.htmZhou B, Wang H G, Zhang F C, et al. Experiments on the influences of temperature and pressure on rock drillability and rock breaking efficiency[J]. Oil Drilling & Production Technology, 2020, 42(5): 547-552(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SYZC202005003.htm [16] 赵金昌, 万志军, 李义, 等. 高温高压条件下花岗岩切削破碎试验研究[J]. 岩石力学与工程学报, 2009, 28(7): 1432-1438. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200907019.htmZhao J C, Wan Z J, Li Y, et al. Research on granite cutting and breaking test under conditions of high temperature and high pressure[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(7): 1432-1438(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200907019.htm [17] 刘石, 许金余. 高温作用对花岗岩动态压缩力学性能的影响研究[J]. 振动与冲击, 2014, 33(4): 195-198. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201404035.htmLiu S, Xu J Y. Effect of high temperature on dynamic compressive mechanical properties of granite[J]. Journal of Vibration and Shock, 2014, 33(4): 195-198(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201404035.htm [18] 吴阳春, 郤保平, 王磊, 等. 高温后花岗岩的物理力学特性试验研究[J]. 中南大学学报: 自然科学版, 2020, 51(1): 193-203. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD202001022.htmWu Y C, Xi B P, Wang L, et al. Experimental study on physico-mechanical properties of granite after high temperature[J]. Journal of Central South University: Science and Technology Edition, 2020, 51(1): 193-203(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD202001022.htm [19] 喻勇, 徐达, 窦斌, 等. 高温花岗岩遇水冷却后可钻性试验研究[J]. 地质科技情报, 2019, 38(4): 287-292. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201904031.htmYu Y, Xu D, Dou B, et al. Experimental study on drillability of high temperature granite after water cooling[J]. Geological Science and Technology Information, 2019, 38(4): 287-292(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201904031.htm [20] 张帆, 操旺进, 胡大伟, 等. 高温水冷后循环加卸载条件下花岗岩的渗透性[J]. 沈阳工业大学学报, 2021, 43(1): 82-90. https://www.cnki.com.cn/Article/CJFDTOTAL-SYGY202101015.htmZhang F, Cao W J, Hu D W, et al. Permeability of granite under cyclic loading and unloading conditions after high temperature water cooling[J]. Journal of Shenyang University of Technology, 2021, 43(1): 82-90(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SYGY202101015.htm [21] 余莉, 彭海旺, 李国伟, 等. 花岗岩高温-水冷循环作用下的试验研究[J]. 岩土力学, 2021, 42(4): 1-11. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202104015.htmYu L, Peng H W, Li G W, et al. Experimental study on granite under the action of high temperature and water cooling[J]. Rock and Soil Mechanics, 2021, 42(4): 1-11(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202104015.htm [22] 张宇皓, 段志波, 张帆. 高温水冷后花岗岩微观孔径及渗透性分析[J]. 科学技术与工程, 2021, 21(1): 297-302. https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS202101042.htmZhang Y H, Duan Z B, Zhang F. Analysis of micro-pore structure and permeability of granite after heating and water quenching[J]. Science Technology and Engineering, 2021, 21(1): 297-302(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS202101042.htm [23] 杨凯, 杨志瑞, 申梓岐. 高温对花岗岩物理及力学性质的影响[J]. 南方农机, 2020, 51(21): 196-198. https://www.cnki.com.cn/Article/CJFDTOTAL-NFLJ202021090.htmYang K, Yang Z R, Shen Z Q. Effects of high temperature on physical and mechanical properties of granites[J]. South Agricultural Machinery, 2020, 51(21): 196-198(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-NFLJ202021090.htm [24] 罗生银, 窦斌, 田红. 自然冷却后与实时高温下花岗岩物理力学性质对比试验研究[J]. 地学前缘, 2020, 27(1): 178-184. https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY202001022.htmLuo S Y, Dou B, Tian H. Comparative experimental study on physical and mechanical properties of granite after natural cooling and under real-time high temperature[J]. Earth Science Frontiers, 2020, 27(1): 178-184(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY202001022.htm [25] 梅冬, 曾石友, 梁丽, 等. 基于微钻试验金刚石钻头钻进速度的研究[J]. 地质科技情报, 2015, 34(2): 221-224. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201502033.htmMei D, Zeng S Y, Liang L, et al. Research on impregnated diamond bit drilling speed based on micro drilling experiment[J]. Geological Science and Technology Information, 2015, 34(2): 221-224(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201502033.htm [26] 田敏, 蔡记华, 谷天本, 等. 高寒地区岩石可钻性分析及金刚石钻头选型[J]. 地质科技情报, 2014, 33(2): 171-174. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201402029.htmTian M, Cai J H, Gu T B, et al. Rock drillability analysis and diamond bit model selection in Alpine regions[J]. Geological Science and Technology Information, 2014, 33(2): 171-174(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201402029.htm [27] 石祥超, 陶祖文, 孟英峰, 等. 牙轮钻头牙齿破岩机理研究进展[J]. 地质科技情报, 2014, 33(4): 225-230. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201404035.htmShi X C, Tao Z W, Meng Y F, et al. The mechanism of rock breakage during bit-tooth penetration: A review[J]. Geological Science and Technology Information, 2014, 33(4): 225-230(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201404035.htm [28] 中石化胜利石油工程有限公司钻井工艺研究院. 石油天然气钻井工程岩石可钻性测定与分级: SY/T 5426-2016[S]. 国家能源局: 2016.Drilling Technology Research Institute of Shengli Petroleum Engineering Corporation Limited, SINOPEC. Drilling engineering for the petroleum and natural gas-rock drillability measurement and its grading: SY/T 5426-2016[S]. National Energy Administration: 2016(in Chinese with English abstract). [29] Kumari W G P, Ranjith P G, Perera M S A, et al. Temperature-dependent mechanical behaviour of Australian Strathbogie granite with different cooling treatments[J]. Engineering Geology, 2017, 229: 31-44. [30] Griffiths L, Heap M J, Baud P, et al. Quantification of microcrack characteristics and implications for stiffness and strength of granite[J]. International Journal of Rock Mechanics and Mining Sciences, 2017, 100: 138-150. [31] 梁铭, 张绍和, 舒彪. 不同冷却方式对高温花岗岩巴西劈裂特性的影响[J]. 水资源与水工程学报, 2018, 29(2): 186-193. https://www.cnki.com.cn/Article/CJFDTOTAL-XBSZ201802031.htmLiang M, Zhang S H, Shu B. Effect of different cooling ways on Brazilian tension characteristics of heat-treated granite[J]. Journal of Water Resources and Water Engineering, 2018, 29(2): 186-193(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-XBSZ201802031.htm [32] 李利峰, 邓慧琳, 张晓虎, 等. 加载速率对实时高温花岗岩三轴力学特性影响的实验研究[J]. 科学技术与工程, 2020, 20(16): 6397-6403. https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS202016013.htmLi L F, Deng H L, Zhang X H, et al. Experimental study on the effect of loading rate on triaxial mechanical properties of real-time high temperature granite[J]. Science Technology and Engineering, 2020, 20(16): 6397-6403(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS202016013.htm [33] 闵明, 张强, 蒋斌松, 等. 实时高温下北山花岗岩劈裂试验及声发射特性[J]. 长江科学院院报, 2020, 37(3): 108-113. https://www.cnki.com.cn/Article/CJFDTOTAL-CJKB202003019.htmMin M, Zhang Q, Jiang B S, et al. Splitting tests and acoustic emission characteristics of Beishan granite under real-time high temperature[J]. Journal of Yangtze River Scientific Research Institute, 2020, 37(3): 108-113(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-CJKB202003019.htm [34] 闫炎, 管志川, 玄令超, 等. 复合冲击条件下PDC钻头破岩效率试验研究[J]. 石油钻探技术, 2017, 45(6): 24-30. https://www.cnki.com.cn/Article/CJFDTOTAL-SYZT201706005.htmYan Y, Guan Z C, Xuan L C, et al. Experimental study on rock breaking efficiency with a PDC bit under conditions of composite percussion[J]. Petroleum Drilling Techniques, 2017, 45(6): 24-30(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SYZT201706005.htm [35] 潘德元, 何计彬. 钻井岩屑分形分析的现场应用研究[J]. 探矿工程: 岩土钻掘工程, 2016, 43(11): 11-14. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC201611003.htmPan D Y, He J B. Research on the field application of analysis on cutting particle size[J]. Exploration Engineering: Rock & Soil Drilling and Tunneling, 2016, 43(11): 11-14(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC201611003.htm [36] 高元宏, 梁俭, 刘鹏, 等. 青海东昆仑重点成矿带岩石钻进特性及金刚石钻头使用效果分析[J]. 地质科技情报, 2017, 36(5): 228-231. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201705031.htmGao Y H, Liang J, Liu P, et al. Characteristics of rock drilling and the effect of diamond bits used in the key metallogenic belt in East Kunlun, Qinghai[J]. Geological Science and Technology Information, 2017, 36(5): 228-231(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201705031.htm [37] Shi X C, Gao L Y, Wu J, et al. Effects of cyclic heating and water cooling on the physical characteristics of granite[J]. Energies, 2020, 13(9): 1-18. [38] Glover P W J, Band P, Darot M, et al. α/β phase transition in quartz monitored using acoustic emissions[J]. Geophysical Journal International, 1995, 120(3): 775-782. -

下载:

下载: