Effect of stimulation in hot dry rock reservoirs from carbon dioxide blasting-induced cracking

-

摘要:

采用二氧化碳爆破致裂为激发干热岩储层提供了一种新的技术思路和途径。为了探究二氧化碳爆破致裂激发干热岩储层的作用效果, 开展了二氧化碳爆破致裂干热岩储层作用范围的数值模拟研究。考虑实际开采过程中钻井液对井壁附近干热岩储层的降温影响, 采用以温差为变量的拟合函数设置损伤区储层材料参数, 用洗井后井壁附近储层温度分布函数设置损伤区储层温度场, 并借助炸药爆破的相关理论、公式设置爆破荷载, 结合COMSOL软件模拟了二氧化碳爆破致裂激发干热岩储层的过程。结果表明, 二氧化碳爆破致裂干热岩过程中存在多次应力集中作用, 且在炮孔附近压应力集中造成压碎区, 压碎区外拉应力作用形成裂隙区; 储层的初始温度以及定压片厚度都会影响二氧化碳爆破致裂激发干热岩储层的作用效果, 其中初始温度对爆破压碎区范围影响较大, 对裂隙区范围影响较小, 定压片厚度改变对压碎区范围影响较小, 主要影响爆破裂隙区的分布。本研究成果可为干热岩地热能后续的开采利用提供理论支持和参考。

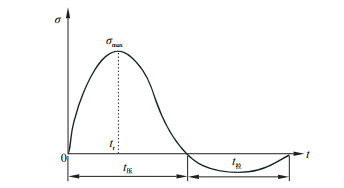

Abstract:Carbon dioxide blasting provides a new technical idea and way to stimulate hot dry rock reservoirs. To explore the effect of carbon dioxide blasting-induced cracking on dry-hot rock reservoirs, a numerical simulation for the action range of carbon dioxide blasting-induced cracking of hot dry rock was carried out. Considering the cooling effect of drilling fluid on the hot dry rock reservoir near the wellbore in the actual mining process, the fitting functions with temperature difference as a variable were adopted to set the material parameters of the reservoir in the damaged area, and the temperature distribution functions of the reservoir near the wellbore after well washing were adopted to set the temperature field of the reservoir in the damaged area. The blasting load was set by the relevant theories and formulas of explosive blasting. Combined with COMSOL software, the process of carbon dioxide blasting to stimulate hot dry rock reservoirs was simulated. The results showed that there were multiple stress concentrations in the process of the dry hot rock cracking caused by carbon dioxide blasting, the compressive stress concentration near the blast hole produced the crushing zone, and the tensile stress outside the crushing zone formed the fracture zone. In addition, the initial temperature of the reservoir and the thickness of the pressure plate would affect the effect of carbon dioxide blasting fracturing to stimulate dry and hot rock reservoirs. The initial temperature had a great influence on the scope of the blasting crushing zone and had little influence on the scope of the fracture zone. The thickness of the pressure plate had little influence on the scope of the crushing zone, which mainly affected the distribution of the blasting fracture zone. The research results could provide a theoretical support and a reference for the subsequent exploitation and utilization of dry-hot rock geothermal energy.

-

Key words:

- hot dry rock /

- reservoir stimulation /

- carbon dioxide blasting /

- geothermal energy /

- numerical model

-

表 1 不同型号致裂器爆破参数

Table 1. Blasting parameters of different types of crackers

致裂器型号 致裂器外径/mm 定压片厚度/mm 等效装药密度/(kg·m-3) 峰值荷载P/MPa(n=8~11) 38型 38 3.5 102.040 8 0.73~1.00 4.0 117.346 9 0.83~1.14 4.5 132.653 1 0.95~1.30 57型 57 4.0 117.476 4 9.56~13.15 4.5 132.704 9 10.80~14.85 5.0 147.933 3 12.04~16.56 95型 95 4.5 132.649 6 231.40~318.16 5.0 148.034 2 258.23~355.07 5.5 163.760 7 285.67~392.80 表 2 不同温度储层应力衰减系数(α)取值

Table 2. Values of the stress attenuation coefficients(α) of reservoir with different temperatures

储层温度 室温(20℃) 300℃ 400℃ 500℃ 600℃ α 2.047 1.960 1.923 1.893 1.825 表 3 未损伤区储层参数

Table 3. Reservoir parameters in damaged area

参数名称 密度ρ0/(g·cm-3) 弹性模量E0/GPa 泊松比μ0 抗拉强度RTS0/MPa 抗压强度UCS0/MPa 取值 2.614 13.22 0.188 12.02 123.44 表 4 损伤区储层参数

Table 4. Reservoir parameters in damaged area

参数名称 拟合方程 密度/(g·cm-3) ρ1=2 600-2 600[ρ%(ΔT)%]

ρ%(ΔT)=0.006 706-0.001 51ΔT+7.748 04×10-6ΔT2弹性模量/GPa E1(ΔT)=2.773 04×10-5ΔT2-0.029 8ΔT+13.223 08 泊松比 μ1(ΔT)=0.188 15+4.333 26×10-5ΔT+2.734 58×10-7ΔT2 抗拉强度/MPa RTS1(ΔT)=12.019 47-0.015 32ΔT-1.989 64×10-7ΔT2 抗压强度/MPa UCS1(ΔT)=-9.589 93×10-5ΔT2-0.086 61ΔT+123.439 94 表 5 不同工况下致裂器参数

Table 5. Parameters of crackers under different working conditions

组别 致裂器型号 定压片厚度/mm 爆破当量/TNT 压力增大系数(n) 工况1 95 5.5 0.479 8 工况2 95 5.0 0.433 11 工况3 95 5.0 0.433 8 工况4 95 4.5 0.388 11 工况5 95 4.5 0.388 8 工况6 57 5.0 0.204 11 表 6 不同工况致裂器爆破激发范围

Table 6. Blasting excitation range of crackers under different working conditions

组别 压碎区长度模拟值/m 裂隙区长度模拟值/m 压碎区长度解析值/m 裂隙区长度解析值/m 工况1 0.1~0.12 0.88~0.98 0.133 1 0.853 7 工况2 0.12~0.14 0.98~1.08 0.140 4 0.900 5 工况3 0.1~0.12 0.88~0.98 0.129 7 0.831 9 工况4 0.1~0.12 0.88~0.98 0.136 6 0.876 1 工况5 0.08~0.1 0.68~0.78 0.126 2 0.809 4 工况6 <0.02 <0.02 0.066 0 0.423 3 -

[1] 周总瑛, 刘世良, 刘金侠. 中国地热资源特点与发展对策[J]. 自然资源学报, 2015, 30(7): 1210-1221.Zhou Z Y, Liu S L, Liu J X. Study on the characteristics and development strategies of geothermal resources in China[J]. Journal of Natural Resources, 2015, 30(7): 1210-1221(in Chinese with English abstract). [2] Hammons T J, Gunnarsson A. Geothermal sustainability in Europe and worldwide[C]//2008 43rd International Universities Power Engineering Conference. IEEE, 2008. [3] 李德威, 王焰新. 干热岩地热能研究与开发的若干重大问题[J]. 地球科学: 中国地质大学学报, 2015, 40(11): 1858-1869.Li D W, Wang Y X. Major issues of research and development of hot dry rock geothermal energy[J]. Earth Science: Journal of China University of Geosciences, 2015, 40(11): 1858-1869(in Chinese with English abstract). [4] Duchane D V. Geothermal energy from hot dry rock: A renew able energy technology moving towards practical implementation[J]. Renewable Energy, 1996, 9(1/4): 1246-1249. [5] 汪集旸, 胡圣标, 庞忠和, 等. 中国大陆干热岩地热资源潜力评估[J]. 科技导报, 2012, 30(32): 25-31. doi: 10.3981/j.issn.1000-7857.2012.32.002Wang J Y, Hu S B, Pang Z H, et al. Estimate of geothermal resources potential for hot dry rock in the continental area of China[J]. Science and Technology Review, 2012, 30(32): 25-31(in Chinese with English abstract). doi: 10.3981/j.issn.1000-7857.2012.32.002 [6] Feng Y, Chen X, Xu X F. Current status and potentials of enhanced geothermal system in China: A review[J]. Renewable and Sustainable Energy Reviews, 2014, 33: 214-223. doi: 10.1016/j.rser.2014.01.074 [7] Huang W, Cao W, Jiang F. A novel single-well geothermal system for hot dry rock geothermal energy exploitation[J]. Energy, 2018, 162: 630-644. doi: 10.1016/j.energy.2018.08.055 [8] 窦斌, 高辉, 周刚, 等. 我国发展增强型地热开采技术所面临的机遇与挑战[J]. 地质科技情报, 2014, 33(5): 208-210. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201405032.htmDou B, Gao H, Zhou G, et al. Opportunities and challenges of developing enhance geothermal system technology in China[J]. Geological Science and Technology Information, 2014, 33(5): 208-210(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201405032.htm [9] 马峰, 蔺文静, 郎旭娟, 等. 我国干热岩资源潜力区深部热结构[J]. 地质科技情报, 2015, 34(6): 176-181.Ma F, Lin W J, Lang X J, at al. Deep geothermal structures of potential hot dry rock resources area in China[J]. Geological Science and Technology Information, 2015, 34(6): 176-181(in Chinese with English abstract). [10] 陆川, 王贵玲. 干热岩研究现状与展望[J]. 科技导报, 2015, 33(19): 13-21.Lu C, Wang G L. Current status and prospect of hot dry rock research[J]. Science and Technology Review, 2015, 33(19): 13-21(in Chinese with English abstract). [11] Cheng Y, Zhang Y, Yu Z, et al. Investigation on reservoir stimulation characteristics in hot dry rock geothermal formations of China during hydraulic fracturing[J]. Rock Mechanics and Rock Engineering, 2021, 54(8): 3817-3845. doi: 10.1007/s00603-021-02506-y [12] Zhang W, Wang C, Guo T, et al. Study on the cracking mechanism of hydraulic and supercritical CO2 fracturing in hot dry rock under thermal stress[J]. Energy, 2021, 221: 119886. doi: 10.1016/j.energy.2021.119886 [13] 徐超, 窦斌, 田红, 等. 二氧化碳爆破致裂建造增强型地热系统热储层工艺探讨[J]. 地质科技情报, 2019, 38(5): 247-252. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201905027.htmXu C, Dou B, Tian H, et al. Process of carbon dioxide blasting to build EGS thermal reservoir[J]. Geological Science and Technology Information, 2019, 38(5): 247-252(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201905027.htm [14] Singh S P. Non-explosive applications of the PCF concept for underground excavation[J]. Tunnelling and Underground Space Technology, 1998, 13(3): 305-311. [15] Vidanovic N, Ognjanovic S, Ilincic N, et al. Application of unconventional methods of underground premises construction in coal mines[J]. Technics Technologies Education Management-Ttem, 2011, 6(4): 861-865. [16] Caldwell T. A comparison of non-explosive rock breaking techniques[C]//Proceedings of the 12th Australian Tunnelling Conference. [S. l. ]: [s. n. ], 2005. [17] 董庆祥, 王兆丰, 韩亚北, 等. 液态CO2相变致裂的TNT当量研究[J]. 中国安全科学学报, 2014, 24(11): 84-88.Dong Q X, Wang Z F, Han Y B, at al. Research on TNT equivalent of liquid CO2 phase-transition fracturing[J]. China Safety Science Journal, 2014, 24(11): 84-88(in Chinese with English abstract). [18] 孙小明. 液态二氧化碳相变致裂穿层钻孔强化预抽瓦斯效果研究[D]. 河南焦作: 河南理工大学, 2014.Sun X M. Research on strengthening gas pre-drainage effect with the fracturing technique by liquid CO2 phase transition in layer through boring[D]. Jiaozuo Henan: Henan Polytechnic University, 2014(in Chinese with English abstract). [19] 秦江涛, 陈玉涛, 黄文祥. 高压水力压裂和二氧化碳相变致裂联合增透技术[J]. 煤炭科学技术, 2017, 45(7): 80-84.Qin J T, Chen Y T, Huang W X. Combined permeability improved technology with high pressure hydraulic fracturing and carbon dioxide phase change cracking[J]. Coal Science and Technology, 2017, 45(7): 80-84(in Chinese with English abstract). [20] 成诗冰, 洪志先. 液态CO2致裂技术在管廊基坑台阶开挖中的应用[J]. 工程爆破, 2021, 27(5): 80-89. https://www.cnki.com.cn/Article/CJFDTOTAL-GCBP202105013.htmCheng S B, Hong Z X. Application of liquid CO2 fracturing technology in bench excavation of utility tunnel foundation pit[J]. Engineering Blasting, 2021, 27(5): 80-89(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-GCBP202105013.htm [21] 周盛涛, 罗学东, 蒋楠, 等. 二氧化碳相变致裂技术研究进展与展望[J]. 工程科学学报, 2021, 43(7): 883-893. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202107002.htmZhou S T, Luo X D, Jiang N, et al. A review on fracturing technique with carbon dioxide phase transition[J]. Chinese Journal of Engineering, 2021, 43(7): 883-893(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202107002.htm [22] 张晋红. 柱状药包在岩石中爆炸应力波衰减规律的研究[D]. 太原: 中北大学, 2005.Zhang J H. Study on the attenuation law of explosion stress wave in rock of cylinder charge[D]. Taiyuan: North University of China, 2005(in Chinese with English abstract). [23] 东兆星, 邵鹏. 爆破工程[M]. 北京: 中国建筑工业出版社, 2004.Dong Z X, Shao P. Blasting engineering[M]. Beijing: China Architecture and Building Press, 2004(in Chinese). [24] 戴俊. 柱状装药爆破的岩石压碎圈与裂隙圈计算[J]. 辽宁工程技术大学学报: 自然科学版, 2001(2): 144-147. https://www.cnki.com.cn/Article/CJFDTOTAL-FXKY200102004.htmDai J. Calculation of rock crushing circle and fissure circle in cylindrical charge blasting[J]. Journal of Liaoning Technical University: Natural Science Edition, 2001(2): 144-147(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-FXKY200102004.htm [25] 史晓鹏, 张银平, 袁本胜. 爆炸荷载作用下应力波衰减规律研究[J]. 矿冶, 2010, 19(3): 15-17. https://www.cnki.com.cn/Article/CJFDTOTAL-KYZZ201003005.htmShi X P, Zhang Y P, Yuan B S. Research on weaken rules of stress wave by explosion loads[J]. Mining and Metallurgy, 2010, 19(3): 15-17(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-KYZZ201003005.htm [26] 朱振南, 田红, 董楠楠, 等. 高温花岗岩遇水冷却后物理力学特性试验研究[J]. 岩土力学, 2018, 39(增刊2): 169-176. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2018S2025.htmZhu Z N, Tian H, Dong N N, et al. Experimental study of physico-mechanical properties of heat-treated granite by water cooling[J]. Rock and Soil Mechanics, 2018, 39(S2): 169-176(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2018S2025.htm [27] 夏杰勤, 窦斌, 徐超, 等. 干热岩热储建造的二氧化碳爆破致裂器优化设计[J]. 钻探工程, 2021, 48(1): 75-80. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202101011.htmXia J Q, Dou B, Xu C, et al. Optimum design of CO2 fracture initiator for thermal reservoir construction in hot dry rock[J]. Drilling Engineering, 2021, 48(1): 75-80(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202101011.htm -

下载:

下载: