Study on the rock-breaking process based on a high-voltage electropulse boring damage model

-

摘要:

高压电脉冲破岩钻进是目前比较具有潜力和接近工业化的一种新型破岩钻进方式。已有的基于PFC2D的高压电脉冲破岩损伤模型未对破岩试验所用的岩石进行参数标定, 无法保证模拟的模型与实际破岩试验的岩石力学性质一致。基于室内单轴压缩和巴西劈裂试验的数据结果对天然岩石进行了参数标定, 通过标定所得的微观参数建立了与高压电脉冲破岩试验尺寸一致的几何模型, 并对高压电脉冲破岩过程进行了仿真研究。仿真结果表明高压电脉冲破岩过程中, 以产生剪切破坏为主, 同时伴随着一定数量的拉张破坏。之后, 利用高压电脉冲破岩试验系统进行了电脉冲破岩试验, 得到了直径60 mm、深度22.5 mm的不规则破碎孔, 并通过点云软件将破碎效果可视化, 放电破岩试验的结果验证了标定所得参数的有效性。最后, 通过标定参数建立的几何模型研究了裂隙对高压电脉冲破岩效果的影响, 结果表明裂隙的存在会降低破岩过程中的能量消耗, 且破碎过程中的破碎区域有向裂隙方向发展的趋势。

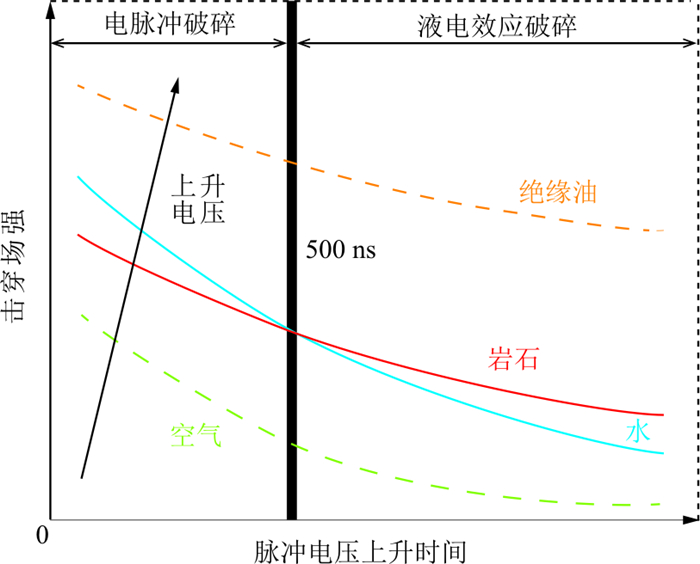

Abstract:High-voltage electropulse boring (EPB) is a new drilling method with great potential for drilling and industrialization. The existing high-voltage electropulse boring damage model based on PFC2D does not calibrate the parameters of the rock used in the rock-breaking test, so it is impossible to ensure that the simulated model is consistent with the mechanical properties of the rock in the actual rock-breaking test. The parameters of natural rock were calibrated based on the data results of indoor uniaxial compression and Brazilian splitting tests. Based on the calibrated micro parameters, a geometric model consistent with the size of the high-voltage EPB test was established, and the EPB process was simulated. The simulation results indicated that the shear failure mainly occurred in the process of high-voltage EPB, accompanied by a certain amount of tensile failure. Then, the EPB test was carried out with the high-voltage EPB test system, and an irregular broken hole with a diameter of 60 mm and a depth of 22.5 mm was obtained. The breaking effect was visualized by point cloud software. The results of the EPB rock-breaking test verified the effectiveness of the calibrated parameters. Finally, the influence of the fractures on the rock-breaking effect of high-voltage EPB was studied through the geometric model established with the calibrated parameters. The results showed that the existence of fractures would reduce the energy consumption in the rock-breaking process, and the crushing area tended to develop in the direction of fractures.

-

表 1 标定所得微观参数组合

Table 1. Combination of microparameters obtained from calibration

颗粒刚度比kn 颗粒接触模量En/GPa 法向黏结强度σc*/MPa 摩擦系数μ 接触刚度比k* 2.4 2.8 15.9 0.5 2.4 平衡黏结模量E*/GPa 黏聚应力c*/MPa 摩擦角φ/(°) 半径乘子λ 2.8 15.9 68 1 表 2 室内试验及模拟所得宏观参数大小

Table 2. Macro parameters obtained from laboratory test and simulations

室内试验实测参数 ν E/GPa UCS/MPa TS/MPa 大小 0.253 3.668 15.584 1.167 模拟所得宏观参数 泊松比ν* E*/GPa UCS*/MPa TS*/MPa 大小 0.258 3.533 15.847 1.126 二者误差/% 1.976 3.821 1.688 3.641 注:ν为泊松比;E为弹性模量;UCS为单轴抗压强度;TS为抗拉强度 -

[1] 张辉, 蔡志翔, 姜敞, 等. 深部岩石高效破碎方法研究[J]. 西部探矿工程, 2018, 30(9): 75-79. doi: 10.3969/j.issn.1004-5716.2018.09.027Zhang H, Cai Z X, Jiang C, et al. Study on efficient crushing method of deep rock[J]. West-China Exploration Engineering, 2018, 30(9): 75-79(in Chinese with English abstract). doi: 10.3969/j.issn.1004-5716.2018.09.027 [2] 闫铁, 杜婕妤, 李玮, 等. 高效破岩前沿钻井技术综述[J]. 石油矿场机械, 2012, 41(1): 50-55. https://www.cnki.com.cn/Article/CJFDTOTAL-SKJX201201013.htmYan T, Du J Y, Li W, et al. Synthesizing comment on efficient rock fragmentation method in frontier drilling technology[J]. Oil Field Equipment, 2012, 41(1): 50-55(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SKJX201201013.htm [3] Hu W, Bao J, Hu B. Trend and progress in global oil and gas exploration[J]. Petroleum Exploration and Development, 2013, 40(4): 439-443. doi: 10.1016/S1876-3804(13)60055-5 [4] 李昌平, 契霍特金V F, 段隆臣. 电脉冲破岩钻进技术研究进展[J]. 地质科技情报, 2018, 37(6): 298-304. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201806038.htmLi C P, Chikhotkin V F, Duan L C. Research progress of electro pulse boring rock breaking technology[J]. Geological Science and Technology Information, 2018, 37(6): 298-304(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201806038.htm [5] Zhu X, Luo Y, Liu W, et al. On the mechanism of high-voltage pulsed fragmentation from electrical breakdown process[J]. Rock Mechanics and Rock Engineering, 2021, 54(9): 4593-4616. doi: 10.1007/s00603-021-02537-5 [6] Kusaiynov K, Nussupbekov B R, Shuyushbayeva N N, et al. On electric-pulse well drilling and breaking of solids[J]. Technical Physics, 2017, 62(6): 867-870. doi: 10.1134/S1063784217060184 [7] Schiegg H O, Rødland A, Zhu G, et al. Electro-pulse-boring (EPB): Novel super-deep drilling technology for low cost electricity[J]. Journal of Earth Science, 2015, 26(1): 37-46. doi: 10.1007/s12583-015-0519-x [8] Li C, Duan L, Wu L, et al. Experimental and numerical analyses of electro-pulse rock-breaking drilling[J]. Journal of Natural Gas Science and Engineering, 2020, 77: 103263. doi: 10.1016/j.jngse.2020.103263 [9] Li C, Duan L, Tan S, et al. Influences on high-voltage electro pulse boring in granite[J]. Energies, 2018, 11(9): 2461. doi: 10.3390/en11092461 [10] 陈鹏宇, 孔莹, 余宏明. 岩石单轴压缩PFC2D模型细观参数标定研究[J]. 地下空间与工程学报, 2018, 14(5): 1240-1249. https://www.cnki.com.cn/Article/CJFDTOTAL-BASE201805013.htmChen P Y, Kong Y, Yu H M. Research on the calibration method of microparameters of a uniaxial compression PFC2D model for rock[J]. Chinese Journal of Underground Space and Engineering, 2018, 14(5): 1240-1249(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-BASE201805013.htm [11] 赵国彦, 戴兵, 马驰. 平行黏结模型中细观参数对宏观特性影响研究[J]. 岩石力学与工程学报, 2012, 31(7): 1491-1498. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201207024.htmZhao G Y, Dai B, Ma C. Study of effects of microparameters on macroproperties for parallel bonded model[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(7): 1491-1498(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201207024.htm [12] 陈鹏宇, 余宏明. 平直节理黏结颗粒材料宏细观参数关系及细观参数的标定[J]. 土木建筑与环境工程, 2016, 38(5): 74-84. https://www.cnki.com.cn/Article/CJFDTOTAL-JIAN201605010.htmChen P Y, Yu H M. Relationship between macroparameters and microparameters of flat-jointed bonded-particle material and calibration of microparameters[J]. Journal of Civil and Environmental Engineering, 2016, 38(5): 74-84(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-JIAN201605010.htm [13] 武鑫星, 黄兴, 王俊杰, 等. 考虑岩石细观结构的PFC模型及一种新的标定流程[J]. 河南科学, 2021, 39(2): 266-275. https://www.cnki.com.cn/Article/CJFDTOTAL-HNKX202102014.htmWu X X, Huang X, Wang J J, et al. PFC model considering rock microstructure and a new calibration process[J]. Henan Science, 2021, 39(2): 266-275(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-HNKX202102014.htm [14] Cho N, Martin C D, Sego D C. A clumped particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(7): 997-1010. http://www.sciencedirect.com/science/article/pii/S1365160907000172 [15] Castro-Filgueira U, Alejano L R, Arzúa J, et al. Sensitivity analysis of the micro-parameters used in a PFC analysis towards the mechanical properties of rocks[J]. Procedia Engineering, 2017, 191: 488-495. http://www.sciencedirect.com/science/article/pii/S1877705817323482/pdf?md5=f503e639aa7eacbddf1e9bb2504a6536&pid=1-s2.0-S1877705817323482-main.pdf&_valck=1 [16] Li C, Duan L, Tan S, et al. Damage model and numerical experiment of high-voltage electro pulse boring in granite[J]. Energies, 2019, 12(4): 727. http://www.xueshufan.com/publication/2916163010 [17] Zhu X, Luo Y, Liu W. On the rock-breaking mechanism of plasma channel drilling technology[J]. Journal of Petroleum Science and Engineering, 2020, 194: 107356. [18] Cho S H, Cheong S S, Yokota M, et al. The dynamic fracture process in rocks under high-voltage pulse fragmentation[J]. Rock Mechanics & Rock Engineering, 2016, 49(10): 1-13. http://www.onacademic.com/detail/journal_1000039526902110_c4a3.html [19] 孙婧, 何佩珊, 齐梦菊. 关于颗粒流软件PFC的离散元数值模拟参数标定[J]. 山东工业技术, 2016(10): 42. https://www.cnki.com.cn/Article/CJFDTOTAL-SDGJ201610040.htmSun J, He P S, Qi M J. On the calibration of discrete element numerical simulation parameters of particle flow software PFC[J]. Shandong Industrial Technology, 2016(10): 42(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-SDGJ201610040.htm [20] 刘畅, 陈晓雪, 张文, 等. PFC数值模拟中平行黏结细观参数标定过程研究[J]. 价值工程, 2017, 36(26): 204-207. https://www.cnki.com.cn/Article/CJFDTOTAL-JZGC201726086.htmLiu C, Chen X X, Zhang W, et al. Study on the calibration process of parallel bonding meso-structure parameter in PFC numerical simulation[J]. Value Engineering, 2017, 36(26): 204-207(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-JZGC201726086.htm [21] Potyondy D O, Cundall P A. A bonded-particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1329-1364. http://www.nstl.gov.cn/paper_detail.html?id=b8cf93b3df102aa14c559af2499d44c2 [22] 何理, 谢先启, 韩传伟, 等. 基于地震波频谱分析与线性叠加的电子雷管延时优选[J]. 金属矿山, 2021(11): 41-48. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202111007.htmHe L, Xie X Q, Han C W, et al. Delay time interval optimization of electronic detonator based on spectrum analysis and linear superposition of seismic wave[J]. Metal Mine, 2021(11): 41-48(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202111007.htm [23] He M, Jiang J, Huang G, et al. Disintegration of rocks based on magnetically isolated high voltage discharge[J]. Review of Scientific Instruments, 2013, 84(2): 61-70. http://www.onacademic.com/detail/journal_1000035857317810_068b.html [24] 官东林, 文国军, 王玉丹, 等. 基于线激光扫描的岩石激光钻孔的三维重建和可视化[J]. 地质科技通报, 2021, 40(3): 173-183. doi: 10.19509/j.cnki.dzkq.2021.0310Guan D L, Wen G J, Wang Y D, et al. 3D reconstruction and visualization for laser drilling hole on rock based on line laser scanning[J]. Bulletin of Geological Science and Technology, 2021, 40(3): 173-183(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2021.0310 -

下载:

下载: