Jacking force calculation method of circular curved pipe jacking with consideration of pipe-soil contact characteristics

-

摘要:

为探究不同管土接触状态下圆曲线顶管顶进力计算方法,结合港珠澳大桥拱北隧道曲线钢顶管工程的相关数据,利用国内外几种常用的曲线顶管顶进力计算公式,以及利用ABAQUS软件建立的考虑注浆作用和管土接触范围的顶进力有限元分析模型,分别进行了顶进力计算。与实测顶进力数据的对比分析表明:①顶进力计算值大小为:JMTA公式≫上海规范公式>Shimada公式,其中考虑1/3管土接触面的Shimada公式下限计算值与实测值较为接近。②通过数值模拟发现,1/3管土接触状态模拟顶进力,逐渐向1/2管土接触状态接近;在注浆状态下,前期实测顶进力接近1/2管土接触状态下的顶进力;后期顶进趋近平稳时,实测顶进力接近1/3管土接触状态下的顶进力。本数值模型能够对同类型工况下顶管顶进力进行较好预测,对实际施工具有一定的指导意义。

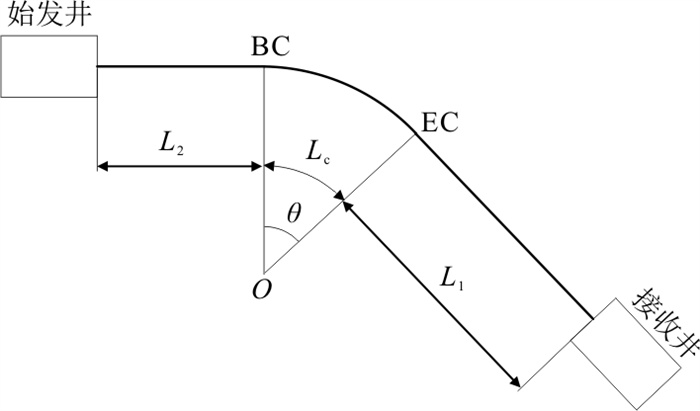

Abstract:To explore the accuracy of the calculation method of the jacking force of circular curved pipe jacking under different pipe-soil contact characteristics, in combination with the curved steel pipe jacking project of Gongbei Tunnel of Hong Kong-Zhuhai-Macao Bridge, this paper adopted several commonly used jacking force calculation formulas for the curved pipe jacking at home and abroad and jacking force finite element analysis model with consideration of grouting effect and the pipe-soil contact range established with ABAQUS to calculate the jacking force. It was found by contrast with the pipe jacking force data: ①The calculated value of jacking force: JMTA formula≫Shanghai normative formula>Shimada formula, where it was considered that the calculated value of the lower limit of Shimada formula of 1/3 pipe-soil contact was relatively close to the measured value. ②Through numerical simulation, it was found that the simulated jacking force of 1/3 pipe-soil contact characteristics was gradually close to the one of 1/2 pipe-soil contact characteristics; in the grouting state, the previously measured jacking force was close to the one of 1/2 pipe-soil contact characteristics. When the jacking force tended to be stable, the measured jacking force was close to the one of 1/3 pipe-soil contact characteristics. Therefore, the numerical model could predict the jacking force of the pipe jacking under the same working condition and had a certain guiding significance for actual construction.

-

Key words:

- curved pipe jacking /

- jacking force /

- numerical simulation /

- pipe-soil contact /

- grouting pressure

-

表 1 曲线顶管顶进力附加系数k值

Table 1. Value of additional coefficient k of jacking force of curved pipe jacking

R 300D 250D 200D 150D 100D k 1.10 1.15 1.20 1.25 1.30 注:R为曲率半径(m);D为管道外径(mm) 表 2 29号顶管相关参数表

Table 2. Related parameters of the No.29 pipe jacking

参数类别 名称 取值 管道几何参数 顶进方向 西→东 圆曲线顶进长度/m 169.7 圆曲线曲率半径/m 905.9 平均长度/m 257.917 平均埋深/m 15.16 刀盘外径/mm 1 676 管道外径/mm 1 620 壁厚/mm 20 开挖地层参数 顶进段Ⅰ岩性及长度/m 淤泥质土(0, 150] 顶进段Ⅱ岩性及长度/m 粗砂、砾砂+淤泥质土(150, 200] 顶进段Ⅲ岩性及长度/m 淤泥质土(200, 250] 表 3 西工作井附近地层参数

Table 3. Formation parameters near the west working well

地层 深度/m 密度/(g·cm-3) 孔隙度 黏聚力/kPa 内摩擦角/(°) 标准贯入度 天然密度 干密度 颗粒密度 人工填土 6.1 1.78 1.54 2.66 0.73 8.0 10.6 8 淤泥质粉质黏土 8.7 1.79 1.31 2.65 1.43 6.0 3.0 5 粉质黏土 13.0 1.96 1.59 2.71 0.62 17.9 10.8 11 淤泥质粉质黏土 18.8 1.79 1.23 2.67 1.11 11.4 4.5 5 粗/砾砂 25.6 2.01 1.83 2.63 0.44 — 30.0 23 砾质黏性土 28.2 1.79 1.36 2.71 1.00 18.2 22.0 14 表 4 上海市《顶管工程施工规程》公式计算参数

Table 4. Formula calculation parameters of "Specification for Construction of Pipe Jacking" in Shanghai

计算参数 取值 备注 顶管机外径Dp/m 1.676 管道外径D/m 1.61 管顶覆土深度Hc/m 13.55 管道埋深与管外径差值 顶进长度L′/m 0~150 淤泥质粉质黏土层 穿越土层黏聚力c/kPa 11.4 淤泥质粉质黏土层 穿越土层内摩擦角φ/(°) 4.5 淤泥质粉质黏土层 单位管周摩阻力f/(kN·m-2) 0.37 文献[6]提供的实测数值 顶进力附加系数k 1~1.1 R/D= 563>400,故取此范围 表 5 日本推進技術協会(JMTA)公式计算参数

Table 5. Calculation parametersof JMTA formula

计算参数 取值 备注 顶管机外径Dp/m 1.676 管道外径D/m 1.61 单位长度管重w/(kN·m-1) 7.89 管顶覆土深度Hc/m 13.55 管道埋深与管外径差值 曲线段长度Lc/m 0~150 不计算直线段 管土摩擦系数k1 0.039 k1=tan(φ/2) 相邻管节偏角a/(°) 0.26 现场实测 曲线段顶管节数n 38 顶进长度与管节长度比值 管土接触面黏聚力Cs/kPa 10 软弱土层 马斯顿土压力q[10] 重度γ/(kN·m-3) 17.9 淤泥质粉质黏土层 黏聚力C/kPa 11.4 淤泥质粉质黏土层 内摩擦角φ/(°) 4.5 淤泥质粉质黏土层 刀盘迎面阻力F0由式(9)与式(10)计算 标准贯入度N 5 淤泥质粉质黏土层 刀盘前泥浆压力pm/kPa 126.6 地下静水压力加上20 kPa 刀盘前切削阻力ps/kPa 150 N<15时取150 kPa 表 6 Shimada公式计算参数

Table 6. Calculation parameters of Shimada formula

表 7 各材料力学参数

Table 7. Mechanical parameters of various materials

土层/结构 深度/m 黏聚力/kPa 内摩擦角/(°) 弹性模量/MPa 密度/(g·cm-3) 泊松比 人工填土 6.1 8.0 10.6 8 1.78 0.30 淤泥质粉质黏土 8.7 6.0 3.0 12 1.79 0.35 粉质黏土 13.0 17.9 10.8 10 1.96 0.32 淤泥质粉质黏土 18.8 11.4 4.5 12 1.79 0.35 粗砂或砾砂 25.6 ─ 30.0 25 2.01 0.35 砾质黏性土 28.2 18.2 22.0 10 1.79 0.32 顶管机 ─ ─ ─ 200 000 1.30 0.30 钢管 ─ ─ ─ 210 000 7.85 0.30 表 8 各顶进段注浆压力

Table 8. Grouting pressure of each jacking section

顶进段/m 6~10 21~25 46~50 71~75 96~100 146~150 平均注浆压力/kPa 0 0 178.0 180.1 169.0 173.2 表 9 3种公式计算结果对比

Table 9. Comparison of the calculation results of three formulas

顶进距离/m 顶进力/kN 上海规范公式 JMTA公式 Shimada公式 实测值 上限 下限 上限 下限 上限 下限 30 863.9 785.4 2 633.8 2 896.9 702.7 439.6 874.2 60 925.6 841.5 4 923.4 5 186.8 795.3 531.9 736.4 90 987.4 897.6 7 216.1 7 479.9 888.0 624.2 609.5 120 1 049.2 953.8 9 512.1 9 776.3 980.8 716.7 735.0 150 1 110.9 1 009.9 11 811.3 12 075.8 1 073.7 809.3 792.2 与实测最小误差/% -1.2 -10.2 201.3 231.4 8.0 2.2 — 表 10 各顶进段模拟顶进力与实测误差

Table 10. Error between simulated jacking force and measured value of each jacking section

顶进距离/m 实测顶进力/kN 1/3接触 1/2接触 顶进力/kN 与实测误差/% 顶进力/kN 与实测误差/% 10 697.6 615.7 -11.7 821.5 17.8 25 781.2 925.3 32.6 1 189.3 70.5 50 706.0 424.6 -39.1 616.4 -11.6 75 676.6 598.8 -14.2 744.9 6.8 100 634.0 745.6 6.9 881.8 26.4 150 924.3 886.6 27.1 1 014.8 45.5 -

[1] 马保松. 非开挖工程学[M]. 北京: 人民交通出版社, 2008.Ma B S. Trenchless engineering[M]. Beijing: People's Communications Press, 2008(in Chinese). [2] 冯鑫, 张鹏, 马保松, 等. 拼装式顶管接头抗弯刚度及管节内力计算[J]. 地质科技通报, 2021, 40(2): 111-117. doi: 10.19509/j.cnki.dzkq.2021.0019Feng X, Zhang P. Ma B S, et al. Joint bending stiffness and internal force calculation of assembled pipe jacking[J]. Bulletin of Geological Science and Technology, 2021, 40(2): 111-117(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2021.0019 [3] 周浩, 周千淼, 谈力昕, 等. 考虑注浆作用的矩形顶管竖向土压力计算模型[J]. 地质科技通报, 2021, 40(2): 125-130. doi: 10.19509/j.cnki.dzkq.2021.0201Zhou H, Zhou Q M, Tan L X, et al. Vertical soil pressure calculation model of rectangular box jacking considering grouting effect[J]. Bulletin of Geological Science and Technology, 2021, 40(2): 125-130(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2021.0201 [4] 马保松, 张雅春. 曲线顶管技术及顶进力分析计算[J]. 岩土工程技术, 2006, 28(5): 229-232, 259. doi: 10.3969/j.issn.1007-2993.2006.05.004Ma B S, Zhang Y C. Curved pipe jacking technology and the calculation of jacking loads for curved section[J]. Geotechnical Engineering Technique, 2006, 28(5): 229-232, 259(in Chinese with English abstract). doi: 10.3969/j.issn.1007-2993.2006.05.004 [5] Shimada H, Khazaei S, Matsui K. Small diameter tunnel excavation method using slurry pipe-jacking[J]. Geotechnical and Geological Engineering, 2004, 22(2): 161-186. doi: 10.1023/B:GEGE.0000018365.84174.ea [6] Shou K J, Jiang J M. A study of jacking force for a curved pipejacking[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2010, 2(4): 298-304. http://www.rockgeotech.org/qikan/manage/wenzhang/2010-04-02.pdf [7] Shou K, Yen J, Liu M. On the frictional property of lubricants and its impact on jacking force and soil-pipe interaction of pipe-jacking[J]. Tunnelling and Underground Space Technology, 2010, 25(4): 469-477. doi: 10.1016/j.tust.2010.02.009 [8] Zhang P, Behbahani S, Ma B S. A jacking force study of curved steel pipe roof in Gongbei Tunnel: Calculation review and monitoring data analysis[J]. Tunnelling & Underground Space Technology, 2018, 72(6): 305-322. http://www.nstl.gov.cn/paper_detail.html?id=3cc9cf1e9d7a53df908f4422a887b60b [9] 张鹏, 谈力昕, 马保松. 考虑泥浆触变性和管土接触特性的顶管摩阻力公式[J]. 岩土工程学报, 2017, 39(11): 2043-2049. doi: 10.11779/CJGE201711012Zhang P, Tan L X, Ma B S. Formulae for frictional resistance considering mud thixotropy and pipe-soil contact characteristics[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(11): 2043-2049(in Chinese with English abstract). doi: 10.11779/CJGE201711012 [10] 张鹏. 拱北隧道超大型曲线顶管管幕施工关键技术及理论研究[D]. 武汉: 中国地质大学(武汉), 2018.Zhang P. Research on key construction techniques and theory of super large curved pipe jacking roof in Gongbei Tunnel[D]. Wuhan: China University of Geosciences(Wuhan), 2018(in Chinese with English abstract). [11] 上海市住房和城乡建设管理委员会. DG/TJ08-2049-2016: 顶管工程施工规程[S]. 上海: 同济大学出版社, 2016.Shanghai Municipal Housing and Urban-Rural Construction Management Committee. DG/TJ08-2049-2016: Construction regulations for pipe jacking project[S]. Shanghai: Tongji University Press, 2016(in Chinese). [12] Japan Micro Tunneling Association. Pipe-jacking application[M]. Tokyo: Japan Micro Tunneling Association, 2013(in Japanese). [13] Yan J X. Numerical simulation for estimation of the jacking force of pipe jacking[D]. [S. l. ]: Department of Civil Engineering, Chung Hsing University, 2015, 2(4): 1-100. [14] Pellet-Beaucour A L, Kastner R. Experimental and analytical study of friction forces during microtunneling operations[J]. Tunnelling and Underground Space Technology, 2002, 17(1): 83-97. doi: 10.1016/S0886-7798(01)00044-X -

下载:

下载: