Optimization of direct-hole cutting blasting technology for deep-buried layered surrounding rock diversion tunnels

-

摘要:

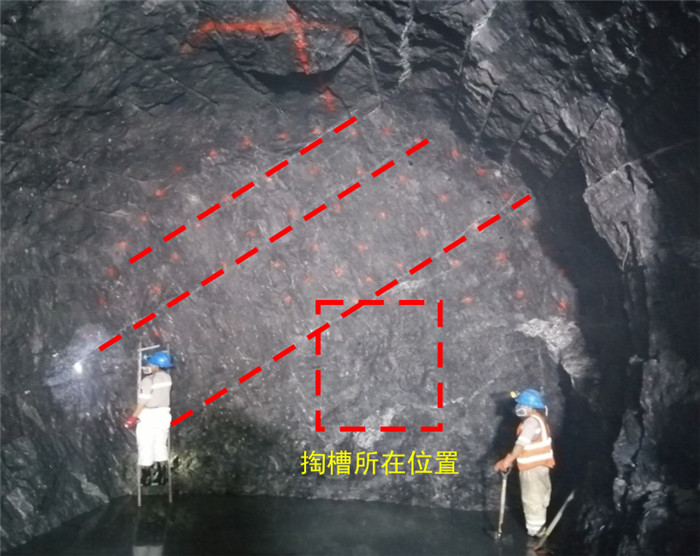

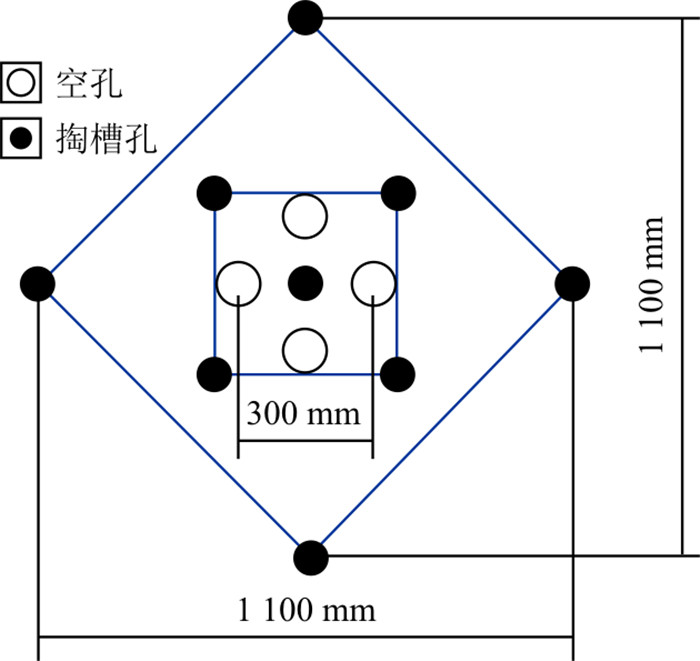

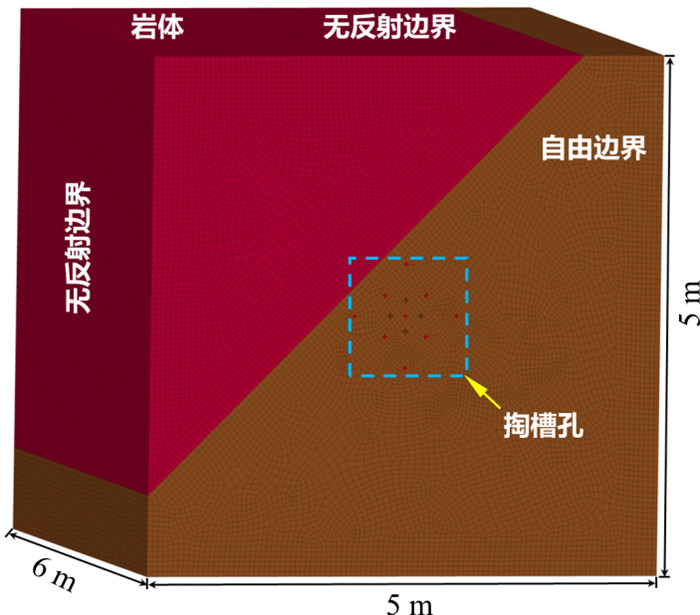

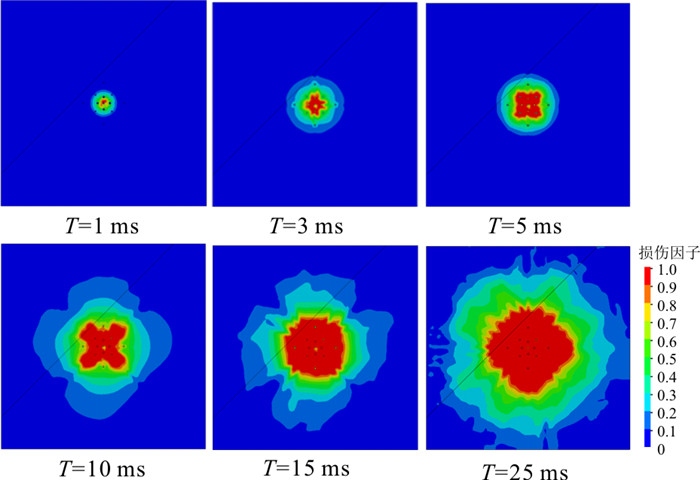

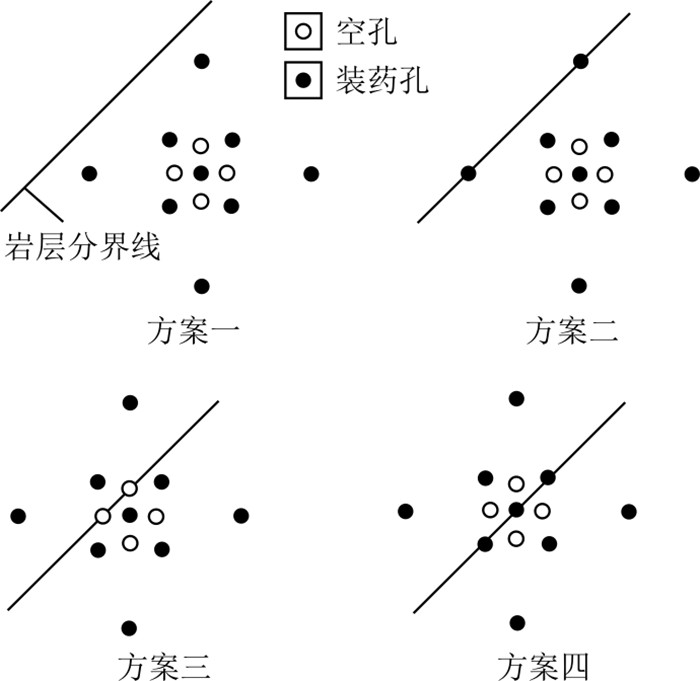

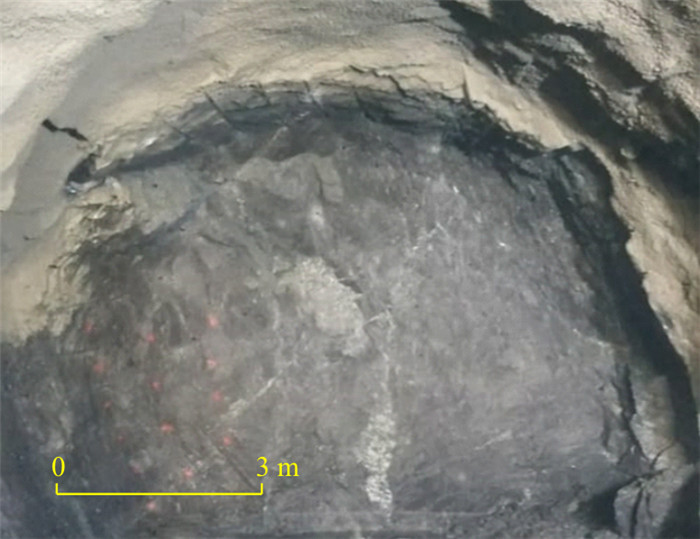

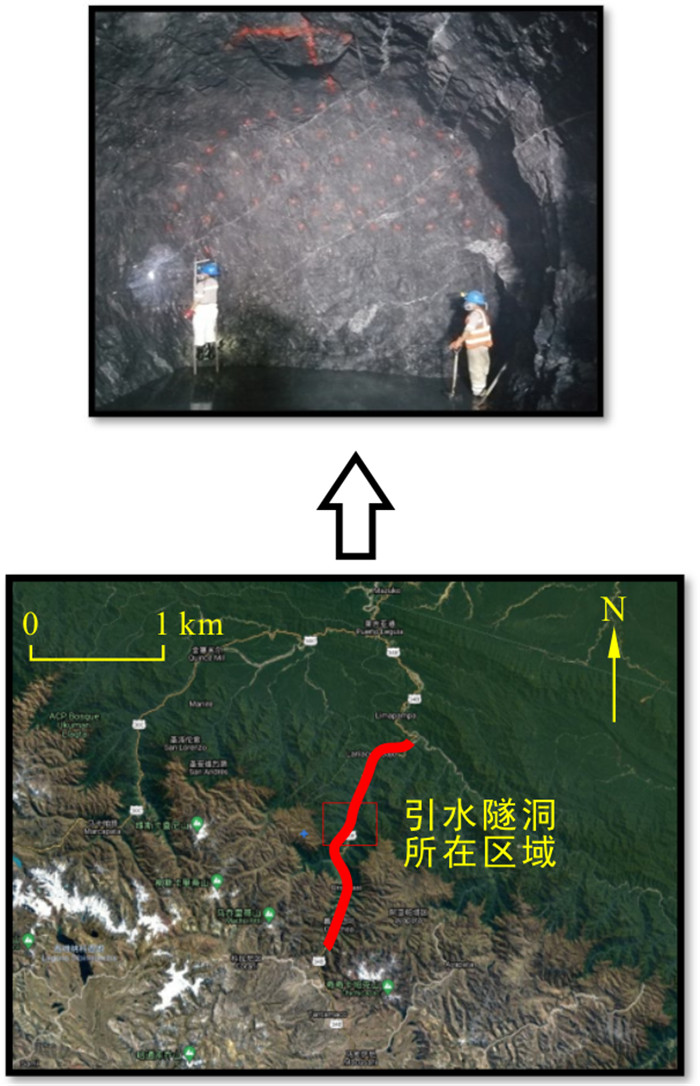

近些年, 隧道爆破施工向纵深延伸的趋势日渐显著, 而深埋引水隧洞中的层状岩体在爆破施工中对掏槽质量的影响是爆破施工的关键。为研究深埋层状围岩中爆破所在位置对掏槽爆破效果的影响, 以秘鲁圣加旺(San Gabán)水电站引水隧洞爆破开挖工程为依托, 利用ANSYS/LS-DYNA建立了三维有限元数值计算模型, 分析了掏槽爆破产生的损伤区域, 提出了优化方案并进行了现场试验。研究结果表明: 层状围岩分界区域对掏槽爆破产生的岩石损伤范围存在一定影响, 离层状围岩分界区域越近岩石损伤的范围越小; 为增加掏槽爆破的损伤区域, 爆破所在位置要与层状围岩的分界区域保持一定的距离; 对优化后的爆破方案进行了现场试验, 取得了较好的爆破效果。利用数值模拟根据岩石损伤演化规律对掏槽孔位置进行优化, 可提高隧道施工的经济性与安全性。

Abstract:Objective In recent years, the trend of tunnel blasting construction extending to depth is becoming more and more significant, and the influence of layered rock mass in deep buried diversion tunnel on cutting quality in blasting construction is the key to blasting construction.

Methods In order to study the influence of the location of blasting in deep layered surrounding rock on the cut blasting, a three-dimensional finite element numerical calculation model was established by using ANSYS/LS-DYNA, based on the blasting excavation project of the diversion tunnel of San Gabán hydropower station in Peru. The damage area caused by cut blasting was analyzed, and the optimization scheme was put forward for field test.

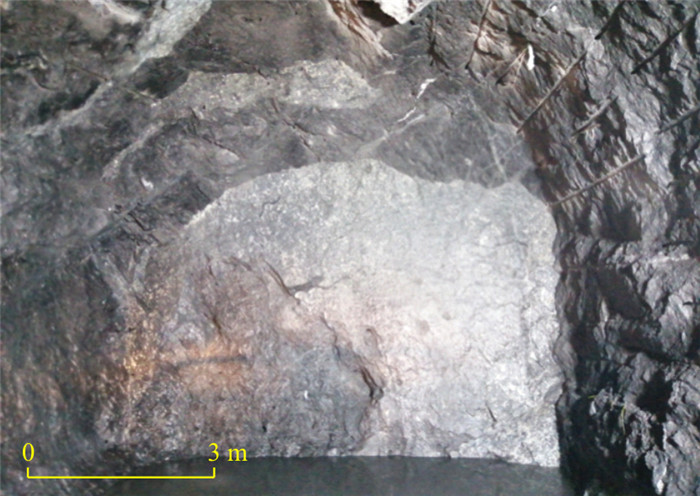

Results The results show that the boundary area of layered surrounding rock has a certain influence on the range of rock damage caused by cutting blasting. The closer to the boundary area of layered surrounding rock, the smaller the range of rock damage. In order to increase the damage area of cut blasting, the location of blasting should keep a certain distance from the boundary area of layered surrounding rock.

Conclusion The optimized blasting scheme was tested on site and good blasting effect was achieved. In this study, numerical simulation was used to optimize the position of the cutting hole accroding to the law of rock damage evolution, which can improve the economy and safety of tunnel construction.

-

Key words:

- blasting damage /

- diversion tunnel /

- cutting blasting /

- numerical simulation /

- layed surrounding rock

-

(所有作者声明不存在利益冲突)

-

表 1 现场地应力实测值

Table 1. In-situ measured stress values

地应力/MPa 水平应力σx 垂直应力σy 实测值 13.73 12.22 表 2 炸药材料参数

Table 2. Explosive material parameters

ρe/(g·cm-3) ve/(m·s-1) A/GPa B/GPa R1 R2 E0/MPa ω 1.15 4 000 214 0.182 4.15 0.95 4.19 0.15 注:ρe为炸药密度;ve为炸药爆速;其余物理量含义见正文 表 3 炮泥材料参数

Table 3. Mud material parameters

ρm/(g·cm-3) E/GPa μ Etan/MPa fy/MPa β 0.85 11 0.35 2 6 0.1 注:ρm为炮泥密度;E为弹性模量;μ为泊松比; Etan为剪切模量;fy为抗拉强度;β为硬化系数 表 4 空气材料参数

Table 4. Air material parameters

绝热指数γ 参考密度ρ/(kg·m-3) 参考温度/K 恒定体积的比热/(J·kg-1·K-1) 1.4 1.225 288.2 717.3 表 5 岩体材料参数

Table 5. Parameters of the rock mass material

ρr/(g·cm-3) G/GPa T/MPa Pc/MPa Pl/MPa μl μc fc/MPa 2.84 11.57 8 48.8 1.2 0.001 2 0.002 5 146.5 A′ B′ C′ N Smax D1 D2 EFmin 0.3 2.5 0.009 7 0.79 15 0.04 1 0.01 注:各物理量的含义见正文 表 6 爆破效果对比

Table 6. Comparison of blasting effect

方案 炮孔深度/m 循环进尺/m 炸药单耗/(kg·m-3) 原方案 3.2 2.60 3.0 方案一 3.2 2.80 2.7 -

[1] Li X, Zhu Z, Wang M, et al. Influence of blasting load directions on tunnel stability in fractured rock mass[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2022, 14(2): 346-365. doi: 10.1016/j.jrmge.2021.06.010 [2] 王雁冰. 爆炸的动静作用破岩与动态裂纹扩展机理研究[D]. 北京: 中国矿业大学(北京), 2016.Wang Y B. Dynamic and static rock breaking and dynamic crack propagation mechanism of explosion[D]. Beijing: China University of Mining and Technology (Beijing), 2016(in Chinese with English abstract). [3] Hashemi A S, Katsabanis P. Tunnel face preconditioning using destress blasting in deep underground excavations[J]. Tunnelling and Underground Space Technology, 2021, 117: 104126. doi: 10.1016/j.tust.2021.104126 [4] Mei W, Xia Y, Pan P Z, et al. Transient responses of deep-buried unlined tunnels subjected to blasting P wave[J]. Computers and Geotechnics, 2022, 146: 104729. doi: 10.1016/j.compgeo.2022.104729 [5] Yang L Y, Ding C X. Fracture mechanism due to blast-imposed loading under high static stress conditions[J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 107: 150-158. doi: 10.1016/j.ijrmms.2018.04.039 [6] 张宇菲. 高地应力岩巷掏槽爆破围压效应模型试验研究[D]. 北京: 中国矿业大学(北京), 2018.Zhang Y F. Model test study on confining pressure effect of cut blasting in high geo-stress rock lane[D]. Beijing: China University of Mining and Technology (Beijing), 2018(in Chinese with English abstract). [7] 穆朝民, 潘飞. 煤体在爆炸荷载和地应力耦合作用下裂纹扩展的数值模拟[J]. 高压物理学报, 2013, 27(3): 403-410. https://www.cnki.com.cn/Article/CJFDTOTAL-GYWL201303015.htmMu C M, Pan F. Numerical simulation of crack propagation in coal under the coupling of explosion load and ground stress[J]. Journal of High Pressure Physics, 2013, 27(3): 403-410(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-GYWL201303015.htm [8] Jayasinghe L B, Shang J, Zhao Z, et al. Numerical investigation into the blasting-induced damage characteristics of rocks considering the role of in-situ stresses and discontinuity persistence[J]. Computers and Geotechnics, 2019, 116: 103207. doi: 10.1016/j.compgeo.2019.103207 [9] Han H, Fukuda D, Liu H, et al. Combined finite-discrete element modelling of rock fracture and fragmentation induced by contour blasting during tunnelling with high horizontal in-situ stress[J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 127: 104214. doi: 10.1016/j.ijrmms.2020.104214 [10] 黄佑鹏, 王志亮, 毕程程. 岩石爆破损伤范围及损伤分布特征模拟分析[J]. 水利水运工程学报, 2018(5): 95-102. https://www.cnki.com.cn/Article/CJFDTOTAL-SLSY201805014.htmHuang Y P, Wang Z L, Bi C C. Simulation analysis of blast-induced damage scope and its distribution characteristics of rocks[J]. Journal of Water Conservancy and Hydraulic Engineering, 2018(5): 95-102(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SLSY201805014.htm [11] 李新平, 宋凯文, 罗忆, 等. 高地应力对掏槽爆破及爆破应力波影响规律的研究[J]. 爆破, 2019, 36(2): 13-18, 53. https://www.cnki.com.cn/Article/CJFDTOTAL-BOPO201902005.htmLi X P, Song K W, Luo Y, et al. Study on influence of high in-situ stress on cut blasting and blast waves[J]. Blasting, 2019, 36(2): 13-18, 53(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-BOPO201902005.htm [12] Miao Y, Li X, Kong L, et al. Study on the symmetric bilinear initiating technique of deep-hole boulder blasting in the TBM tunnel excavation[J]. Tunnelling and Underground Space Technology, 2021, 111: 103871. doi: 10.1016/j.tust.2021.103871 [13] Luo X, Zhou S, Huang B, et al. Effect of freeze-thaw temperature and number of cycles on the physical and mechanical properties of marble[J]. Geotechnical and Geological Engineering, 2021, 39: 567-582. doi: 10.1007/s10706-020-01513-0 [14] Zhu B, Jiang N, Zhou C, et al. Dynamic failure behavior of buried cast iron gas pipeline with local external corrosion subjected to blasting vibration[J]. Journal of Natural Gas Science and Engineering, 2021, 88: 103803. doi: 10.1016/j.jngse.2021.103803 [15] Zhu B, Jiang N, Zhou C, et al. Dynamic failure behavior of buried cast iron gas pipeline with local external corrosion subjected to blasting vibration[J]. Journal of Natural Gas Science and Engineering, 2021, 88: 103803. doi: 10.1016/j.jngse.2021.103803 [16] Xia Y, Jiang N, Zhou C, et al. Theoretical solution of the vibration response of the buried flexible HDPE pipe under impact load induced by rock blasting[J]. Soil Dynamics and Earthquake Engineering, 2021, 146: 106743. doi: 10.1016/j.soildyn.2021.106743 [17] Grady D E, Kipp M E. Continuum modeling of explosive fracture in oil shale[J]. International Journal of Rock and Mining Science, 1980, 17(3): 147-157. [18] 钟权, 彭峥, 刘放. 玉瓦水电站引水隧洞爆破开挖损伤特性研究[J]. 人民长江, 2016, 47(23): 102-106, 125. https://www.cnki.com.cn/Article/CJFDTOTAL-RIVE201623022.htmZhong Q, Peng Z, Liu F. Study on blasting excavation damage characteristics of diversion tunnel of Yuwa Hydropower Station[J]. Renmin Yangtze River, 2016, 47(23): 102-106, 125(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-RIVE201623022.htm [19] 张理维, 王卫华, 戴怡文. 基于岩石爆破损伤的炮孔布置优化研究[J]. 爆破, 2020, 37(1): 32-39. https://www.cnki.com.cn/Article/CJFDTOTAL-BOPO202001007.htmZhang L W, Wang W H, Dai Y W. Optimization of blast hole layout based on rock blasting damage[J]. Blasting, 2020, 37(1): 32-39 (in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-BOPO202001007.htm [20] 徐超, 窦斌, 田红, 等. 二氧化碳爆破致裂建造增强型地热系统热储层工艺探讨[J]. 地质科技情报, 2019, 38(5): 247-252. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201905027.htmXu C, Dou B, Tian H, et al. Process of carbon dioxide blasting to build EGS thermal reservoir[J]. Geological Science and Technology Information, 2019, 38(5): 247-252(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201905027.htm [21] 陈鸿, 欧阳宇峰, 余海忠. 抛石爆破挤淤过程的有限元数值模拟[J]. 地质科技情报, 2012, 31(4): 98-105. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201204018.htmChen H, Ouyang Y F, Yu H Z. Finite element simulation to the process of explosion replacement[J]. Geological Science and Technology Information, 2012, 31(4): 98-105 (in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201204018.htm -

下载:

下载: