Drilling process simulation and dynamic characteristic analysis of soft-hard-staggered strata based on Abaqus

-

摘要:

随着钻探技术向深部地层发展, 研究钻进过程中钻头与深部复杂地层的动态特性及参数响应规律成为研究中的重难点。采用数值模拟和响应面分析相结合的方法, 研究了聚晶金刚石复合片(PDC)钻头与典型复合地层在钻进破坏过程中的动力学特性, 并对其进行了参数分析; 以带倾角的软硬交错地层作为典型复杂地层为研究对象, 基于Abaqus建立了全真尺寸的PDC钻头与软硬交错地层之间的动态破坏有限元仿真模型, 得出了钻头在钻进过程中受到地层反力的动态特性; 通过正交试验进行了数值仿真试验, 研究了在不同的地层参数及钻进参数下PDC钻头的动力学特性; 采用单一因素分析法和响应面分析法对钻进参数及地层参数与钻头受到地层反力之间的关系进行了建模与辨识, 得到了多参数下钻头受到的地层反力变化趋势及回归模型。研究结果表明: 软硬地层倾角越大, 钻头受到的地层反力平均值和冲击峰值亦越大。随着地层软硬程度比的增大, 钻头受到的平均反力和峰值反力大幅增长。在一定范围内, 增大转速会降低钻头受到的反力冲击。研究成果可以为深部复杂地层钻进时钻头反力的预测提供依据, 同时对深部复杂地层钻进轨迹控制起指导作用, 对地质深部钻进有重要意义。

Abstract:Objective With the development of drilling technology for deep strata, the study of the dynamic characteristics and parametric response law of drill bits and deep complex strata during drilling has become a key and difficult point in research.

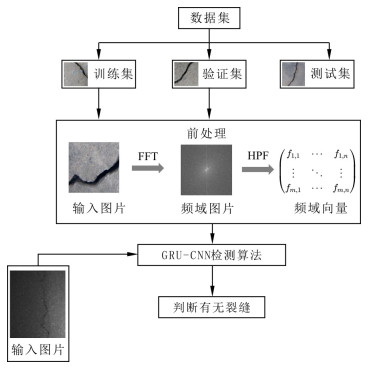

Methods In this paper, a combination of numerical simulation and response surface analysis was used to study the dynamic characteristics of PDC bits and typical complex strata in the drilling process, and parametric analysis was carried out. In this paper, soft-hard-staggered strata with dip angles as a typical complex formation were studied, the dynamic damage finite element simulation model between the PDC drill bit and the soft-hard-staggered strata with the full real size was established based on Abaqus, and the dynamic characteristics of the drill bit subjected to the reaction force of the strata during drilling were derived. Numerical simulation experiments were also conducted by orthogonal tests to investigate the dynamic characteristics of the PDC bit under different formation parameters and drilling parameters.

Results The single factor analysis and response surface analysis were used to model and identify the relationship between drilling parameters and stratigraphic parameters and the reaction force on the drill bit by the stratum and to obtain the changing trend and regression model of the reaction force on the drill bit by the stratum under multiple parameters. The results showed that the higher the inclination angle of soft-hard-staggered strata, the higher the average value and peak impact value of the bit subjected to the stratigraphic reaction force. The larger the ratio of softness to the hardness of the strata is, the larger the average and peak reaction forces on the drill bit. Within a certain range, increasing the rotational speed will reduce the impact of the reaction force on the drill bit.

Conclusion The research results provide a basis for predicting the bit reaction force during drilling in deep and complex formations and guide the control of the drilling trajectory in deep and complex formations, which is of great significance for deep geological drilling.

-

表 1 钻头与地层几何模型参数

Table 1. Geometry model parameters of bit and formation

模型尺寸 直径/mm 边长/mm 轴向尺寸/mm 切削齿尺寸/mm 刀翼数 PDC钻头 215.9 — 328 13 6 岩石 — 1 000 500 — — 表 2 显式动力学分析用材料物理参数

Table 2. Material physical parameters for explicit dynamic analysis

模型材料 密度/(t·mm-3) 杨氏模量/MPa 泊松比 钻头 7.82×10-9 206 000 0.29 软岩 2.1×10-9 5 300 0.35 硬岩 2.5×10-9 27 600 0.30 表 3 显式动力学分析用岩土力学参数

Table 3. Geotechnical mechanics parameters for explicit dynamic analysis

模型材料 摩擦角/(°) 流应力比 膨胀角/(°) Drucker-Prager屈服应力/MPa 剪切损伤的断裂应变 软岩 25 1.0 10 20.26 0.06 硬岩 53 0.8 28 60.78 0.15 表 4 正交试验表(3因素6水平)

Table 4. Orthogonal test table (3 factors and 6 levels)

编号 因素1 (地层倾角水平) 因素2 (软硬程度比水平) 因素3 (机械转速水平) 1 1 5 5 2 2 1 1 3 3 3 3 4 4 6 6 5 5 2 2 6 6 4 4 7 4 1 4 8 5 3 6 9 6 5 2 10 1 6 2 11 2 2 4 12 3 4 6 13 4 5 3 14 5 1 5 15 6 3 1 16 1 4 1 17 2 6 3 18 3 2 5 19 1 1 3 20 2 3 5 21 3 5 1 22 1 2 6 23 2 4 2 24 3 6 4 25 4 4 5 26 5 6 1 27 6 2 3 28 4 3 2 29 5 5 4 30 6 1 6 31 4 2 1 32 5 4 3 33 6 6 5 34 1 3 4 35 2 5 6 36 3 1 2 注:因素1水平1为0°,水平2为15°,水平3为30°,水平4为45°,水平5为60°,水平6为75°;因素2水平1为1,水平2为2,水平3为4,水平4为6,水平5为8,水平6为10;因素3水平1为1 r/s,水平2为2 r/s,水平3为3 r/s,水平4为4 r/s,水平5为5 r/s,水平6为6 r/s 表 5 径向力Fx均值二次多项式模型方差分析

Table 5. Radial force Fx mean quadratic polynomial model variance

方差来源 均方 自由度 平方和 P值 模型 1.70×1011 9 6.04×1012 < 0.000 1** 线性 1.37×1011 3 4.56×1010 < 0.000 1** θ 4.54×1010 1 4.54×1010 < 0.000 1** e 7.33×1010 1 7.33×1010 < 0.000 1** n 1.78×1010 1 1.78×1010 < 0.000 1** 平方 6.84×109 3 2.28×109 0.014* θ·θ 2.10×109 1 2.10×109 0.058 e·e 5.23×108 1 5.23×108 0.331 n·n 4.22×109 1 4.22×109 0.009* 双因子交互 3.59×1010 3 1.20×1010 < 0.000 1** θ·e 1.95×1010 1 1.95×1010 < 0.000 1** θ·n 4.84×109 1 4.84×109 0.006* e·n 1.26×1010 1 1.26×1010 < 0.000 1** 误差 1.39×1010 26 5.33×108 合计 1.84×1011 35 注:“**”(P < 0.000 1)表示此项交互影响极显著,“*”(P < 0.05)表示显著 -

[1] 魏俊浩, 李鹏, 李义邦, 等. 青海省锡铁山铅锌矿成矿元素物质场结构及深部找矿潜力[J]. 地质科技通报, 2021, 40(2): 1-12. doi: 10.19509/j.cnki.dzkq.2021.0203Wei J H, Li P, Li Y B, et al. Material fields structure of ore-forming elements and deep prospecting potential of Xitieshan lead-zinc deposit, Qinghai Province[J]. Bulletin of Geological Science and Technology, 2021, 40(2): 1-12(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2021.0203 [2] 杜学斌, 陆永潮, 曹强, 等. 东海盆地西湖凹陷深部储层"相-岩-温"三元分级评价原则与效果[J]. 地质科技通报, 2020, 39(3): 10-19. doi: 10.19509/j.cnki.dzkq.2020.0302Du X B, Lu Y C, Cao Q, et al. Grading evaluation of deep reservoir in Xihu Depression, East China Sea Basin[J]. Bulletin of Geological Science and Technology, 2020, 39(3): 10-19(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2020.0302 [3] 滕吉文. 强化第二深度空间金属矿产资源探查, 加速发展地球物理勘探新技术与仪器设备的研制及产业化[J]. 地球物理学进展, 2010, 25(3): 729-748. doi: 10.3969/j.issn.1004-2903.2010.03.001Teng J W. Strengthening exploration of metallic minerals in the second depth space of the crust, accelerating development and industrialization of new geophysical technology and instrumental equipment[J]. Progress in Geophysics, 2010, 25(3): 729-748(in Chinese with English abstract). doi: 10.3969/j.issn.1004-2903.2010.03.001 [4] 曹新志, 张旺生, 孙华山. 我国深部找矿研究进展综述[J]. 地质科技情报, 2009, 28(2): 104-109. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ200902018.htmCao X Z, Zhang W S, Sun H S. Progress in the study of deep exploration in China[J]. Geological Science and Technology Information, 2009, 28(2): 104-109 (in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ200902018.htm [5] 谢和平. 深部岩体力学与开采理论研究进展[J]. 煤炭学报, 2019, 44(5): 1283-1305. doi: 10.13225/j.cnki.jccs.2019.6038Xie H P. Research review of the state key research development program of China: Deep rock mechanics and mining theory[J]. Journal of China Coal Society, 2019, 44(5): 1283-1305 (in Chinese with English abstract). doi: 10.13225/j.cnki.jccs.2019.6038 [6] Sakmar S L. Shale gas developments in North America: An overview of the regulatory and environmental challenge facing the industry[C]//Anon. North American Unconventional Gas Conference and Exhibition. [S. l. ]: OnePetro, 2011. [7] 况雨春, 马德坤, 刘清友, 等. 钻柱-钻头-岩石系统动态行为仿真[J]. 石油学报, 2001, 22(3): 81-85. https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB200103021.htmKuang Y C, Ma D K, Liu Q Y, et al. Computer simulation on dynamic action of drillstring-bit-rock system[J]. Acta Petrolei Sinica, 2001, 22(3): 81-85(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SYXB200103021.htm [8] 彭旭, 胡文礼, 艾志久, 等. 软硬交接地层导向孔钻进轨迹预测[J]. 石油矿场机械, 2013, 42(7): 19-22. https://www.cnki.com.cn/Article/CJFDTOTAL-SKJX201307005.htmPeng X, Hu W L, Ai Z J, et al. Prediction of guide hole drilling trajectory of hard and soft staggered formation[J]. Oil Field Equipment, 2013, 42(7): 19-22(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SKJX201307005.htm [9] Kuang Y, Zhang M, Feng M, et al. Simulation and experimental research of PDC bit cutting rock[J]. Journal of Failure Analysis and Prevention, 2016, 16(6): 1101-1107. [10] Gan C, Cao W, Wu M, et al. Intelligent Nadaboost-ELM modeling method for formation drillability using well logging data[J]. Journal of Advanced Computational Intelligence and Intelligent Informatics, 2016, 20(7): 1103-1111. [11] 杨明军, 文国军, 王玉丹, 等. 基于离线编程的煤层智能定向钻进技术[J]. 煤田地质与勘探, 2017, 45(5): 167-172. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201705029.htmYang M J, Wen G J, Wang Y D, et al. Research on off-line programming-based intelligent directional drilling technology of coal seam[J]. Coal Geology & Exploration, 2017, 45(5): 167-172(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201705029.htm [12] Zhang Z, Zhao D, Zhao Y, et al. Simulation and experimental study on temperature and stress field offullsized PDC bits in rock breaking process[J]. Journal of Petroleum Science and Engineering, 2020, 186: 106679. [13] Yarali O, Soyer E. The effect of mechanical rock properties and brittleness on drill ability[J]. Scientific Research and Essays, 2011, 6(5): 1077-1088. [14] Marck J, Detournay E, Kuesters A, et al. Analysis of spiraled borehole data by use of a novel directional. drilling model[J]. SPE Drilling & Completion, 2014, 29(3): 267-278. [15] Ataei M, KaKaie R, Ghavidel M, et al. Drilling rate prediction of an open pit mine using the rock mass drillability index[J]. International Journal of Rock Mechanics and Mining Sciences, 2015, 73: 130-138. [16] Su O. Performance evaluation of button bits in coal measure rocks by using multiple regression analyses[J]. Rock Mechanics and Rock Engineering, 2016, 49(2): 541-553. [17] 谭明健, 周春梅, 孙东, 等. 软硬互层顺层岩质边坡破坏试验[J]. 地质科技通报, 2022, 41(2): 274-281, 324. doi: 10.19509/j.cnki.dzkq.2021.0096Tan M J, Zhou C M, Sun D, et al. Failure experiment of soft-hard interlayer bedding rock slope[J]. Bulletin of Geological Science and Technology, 2022, 41(2): 274-281, 324(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2021.0096 [18] 张文彪, 段太忠, 刘彦锋, 等. 定量地质建模技术应用现状与发展趋势[J]. 地质科技情报, 2019, 38(3): 264-275. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201903029.htmZhang W B, Duan T Z, Liu Y F, et al. Application status and development trend of quantitative geological modeling[J]. Geological Science and Technology Information, 2019, 38(3): 264-275(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201903029.htm [19] Song H, Shi H, Ji Z, et al. The percussive process and energy transfer efficiency of percussive drilling with consideration of rock damage[J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 119: 1-12. [20] Wu J, Zhang S, Ding X, et al. Abrasion rule of polycrystalline diamond compact bit cutter[J]. Journal of Failure Analysis and Prevention, 2019, 19(4): 1135-1143. [21] Yari N, Kapitaniak M, Vaziri V, et al. Calibrated FEM modelling of rock cutting with PDC cutter[C]//Anon. MATEC web of conferences. [S. l. ]: [s. n. ], 2018. [22] 陈正汉. 非饱和土与特殊土力学的基本理论研究[J]. 岩土工程学报, 2014, 36(2): 201-272. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201402002.htmChen Z H. On basic theories of unsaturated soils and special soils[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(2): 201-272(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201402002.htm [23] 姚仰平, 张丙印, 朱俊高. 土的基本特性、本构关系及数值模拟研究综述[J]. 土木工程学报, 2012, 45(3): 127-150. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201203020.htmYao Y P, Zhang B Y, Zhu J G. Behaviors constitutive models and numerical simulation of soils[J]. China Civil Engineering Journal, 2012, 45(3): 127-150 (in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201203020.htm [24] 谢豆. 深部硬地层PDC-牙轮复合钻头破岩机理研究[D]. 成都: 西南石油大学, 2016.Xie D. Research on rock breaking mechanism of PDC-roller cone bit in deep hard formation[D]. Chengdu: Southwest Petroleum University, 2016(in Chinese with English abstract). -

下载:

下载: