A method for detecting the dissemination size of metal minerals under the microscope based on deep learning

-

摘要:

目标矿物嵌布粒度是指目标矿物在矿石中的粒度大小和分布情况, 直接影响着选矿工艺的设计和效果。因此, 目标矿物嵌布粒度测量是工艺矿物学研究中的重要任务之一。在传统工艺矿物学研究中, 主要利用偏光显微镜对矿石样品进行观察分析的方法, 普遍存在处理时间长、结果易受人为主观影响、难以实现自动化和大规模应用等问题。为克服传统方法的局限性, 提出一种基于深度学习的金属矿物镜下嵌布粒度检测方法。以河北省唐山市水厂磁铁矿矿石标本为对象, 在偏光显微镜的反射光条件下进行拍摄, 制作数据集, 利用Deeplabv3+网络设计了矿物识别网络模型, 实现对目标金属矿物的自动化特征提取和智能识别, 并生成目的金属矿物的二值化图像, 从而实现对目的金属矿物的分割; 最后, 结合最大Feret直径完成目的金属矿物嵌布粒度分析测量工作。相较于传统的人工镜下测量方法, 基于深度学习的图像测量在矿物颗粒分析中的应用, 在测量相同矿物颗粒的情境下, 处理速度提高了约119.8倍, 同时测量精度提升了约169.5倍, 揭示了其在处理效率和测量精度上的显著优势。基于深度学习的金属矿物镜下嵌布粒度检测方法显著缩短了矿物镜下嵌布粒度的检测时间并提升了检测精度, 同时可消除人为主观因素的影响, 对于促进工艺矿物学智能化发展有重要意义。

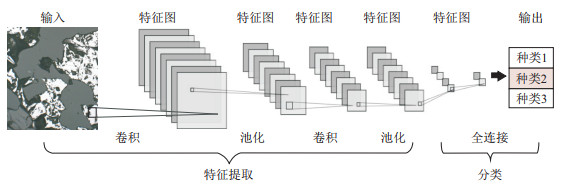

Abstract:Objective The embedded granularity of target minerals refers to their particle size and distribution in ore, which directly influences the design and effectiveness of ore beneficiation processes. Therefore, the measurement of embedded granularity of target minerals is a crucial task in process mineralogy research. In traditional process mineralogy research, the main method for observing and analysing ore samples is to use a polarized light microscopy. However, this approach generally suffers from problems such as long processing times, susceptible to subjective factors, and difficulties in achieving automation and large-scale applications. To overcome these limitations, this paper proposes a method for detecting the embedded granularity of metal minerals under the microscope based on based on deep learning.

Methods This method takes specimens from the Shuichang magnetic ore deposit in Tangshan City, Hebei Province as the object. We take photographs under the reflected light conditions using a polarized light microscope to create a dataset, and design a mineral recognition network model based on the Deeplabv3+ network. Thereby it enables automated feature extraction and intelligent recognition of the target metal minerals. This method achieves segmentation of the target minerals by generating binary images of the desired metal minerals. Finally, the analysis and measurement of the embedded granularity of the target metal minerals are completed by combining the maximum Feret diameter.

Results Compared with traditional manual microscopic measurement methods, the application of image measurement based on deep learning in mineral particle analysis has increased the processing speed by approximately 119.8 times and the measurement accuracy 169.5 times when measuring the same mineral particles, demonstrating its significant improvement in terms of processing efficiency and measurement accuracy.

Conclusion The deep learning-based method for detecting the embedded granularity of metal minerals under a microscope significantly reduces the detection time and enhances the detection accuracy for mineral embedded granularity. Moreover, it eliminates the influence of subjective factors, which is of great significance for promoting the intelligent development of process mineralogy.

-

表 1 矿物识别结果

Table 1. Results of the mineral recognition

矿物种类 MIoU/% MPA/% 磁铁矿 96.77 98.50 非磁铁矿 98.38 99.12 注:MIoU.平均交并比;MPA.平均像素准确率 表 2 图像识别结果测量数据

Table 2. Measurement data of the image recognition result

编号 粒径/μm 编号 粒径/μm 编号 粒径/μm 编号 粒径/μm 1 13.02 11 6.06 21 8.28 31 11.43 2 14.36 12 17.19 22 26.85 32 5.73 3 17.56 13 6.80 23 35.33 33 56.53 4 13.69 14 17.81 24 6.83 34 14.13 5 4.33 15 56.87 25 125.10 35 18.95 6 25.50 16 13.74 26 24.29 36 7.81 7 9.17 17 17.47 27 40.57 37 19.48 8 5.37 18 10.17 28 6.12 9 7.47 19 60.25 29 18.61 10 11.85 20 7.17 30 17.50 表 3 人工测量结果数据

Table 3. Manual measurement results

编号 粒径/mm 编号 粒径/mm 编号 粒径/mm 编号 粒径/mm 1 0.01 11 0.01 21 0.01 31 0.01 2 0.01 12 0.02 22 0.03 32 0.01 3 0.02 13 0.01 23 0.04 33 0.06 4 0.01 14 0.02 24 0.01 34 0.01 5 0.01 15 0.06 25 0.13 35 0.02 6 0.03 16 0.01 26 0.02 36 0.01 7 0.01 17 0.02 27 0.04 37 0.02 8 0.01 18 0.01 28 0.01 9 0.01 19 0.06 29 0.02 10 0.01 20 0.01 30 0.02 -

[1] CASALI A, GONZALEZ G, VALLEBUONA G, et al. Grindability soft-sensors based on lithological composition and on-line measurements[J]. Minerals Engineering, 2001, 14(7): 689-700. doi: 10.1016/S0892-6875(01)00065-6 [2] LOTTER N O, KORMOS L J, OLIVEIRA J, et al. Modern process mineralogy: Two case studies[J]. Minerals Engineering, 2011, 24(7): 638-650. doi: 10.1016/j.mineng.2011.02.017 [3] IVANNIKOV A, CHUMAKOV A, PRISCHEPOV V, et al. Express determination of the grain size of nickel-containing minerals in ore material[J]. Materials Today: Proceedings, 2021, 38: 2059-2062. doi: 10.1016/j.matpr.2020.10.141 [4] 罗朝熙, 和丽芳, 杨昌洲, 等. 基于K-means的金属矿物光片嵌布粒度测量[J]. 有色金属工程, 2022, 12(7): 125-131. https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS202207016.htmLUO C X, HE L F, YANG C Z, et al. Particle size measurement of metallic minerals polished section based on K-means[J]. Nonferrous Metals Engineering, 2022, 12(7): 125-131. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS202207016.htm [5] 陈华勇, 程佳敏, 张俊岭. 多维度矿床学研究: 现状与未来展望[J]. 地质科技通报, 2022, 41(5): 1-4. doi: 10.19509/j.cnki.dzkq.2022.0243CHEN H Y, CHENG J M, ZHANG J L. Multidimensional study of ore deposits: Current status and future prospects[J]. Bulletin of Geological Science and Technology, 2022, 41(5): 1-4. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2022.0243 [6] 聂轶苗, 高培程, 张晋霞, 等. 基于人工神经网络系统的选矿指导子模块的构建[J]. 中国矿业, 2015, 24(增刊1): 364-367. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA2015S1092.htmNIE Y M, GAO P C, ZHANG J X, etal. Establishment of ore separation sub-modules based on artificial neural network[J]. China Mining Magazine, 2015, 24(S1): 364-367. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA2015S1092.htm [7] 许潇, 张文阁, 池顺鑫. 基于圆形拟合识别算法的颗粒粒度粒形自动测量方法研究[J]. 计量科学与技术, 2021, 65(3): 15-18. https://www.cnki.com.cn/Article/CJFDTOTAL-JLJS202103003.htmXU X, ZHANG W G, CHI S X. Automatic particle measurement method based on circle fitting aided recognition algorithm[J]. Metrology Science and Technology, 2021, 65(3): 15-18. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JLJS202103003.htm [8] 方梦阳, 何建宁, 王万虎, 等. 一种基于MATLAB的碎屑岩粒度分析方法[J]. 岩石矿物学杂志, 2020, 39(4): 504-510. https://www.cnki.com.cn/Article/CJFDTOTAL-YSKW202004009.htmFANG M Y, HE J N, WANG W H, et al. A particle size analysis method for clastic rock based on MATLAB[J]. Acta Petrologica et Mineralogica, 2020, 39(4): 504-510. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YSKW202004009.htm [9] 汤化明, 王玲, 杨国华, 等. 人工智能在矿物加工技术中的应用与发展[J]. 金属矿山, 2022(2): 1-9. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202202001.htmTANG H M, WANG L, YANG G H, et al. Application and development of artificial intelligence in mineral processing technology[J]. Metal Mine, 2022(2): 1-9. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202202001.htm [10] 马泽栋, 马雷, 李科, 等. 基于岩石图像深度学习的多尺度岩性识别[J]. 地质科技通报, 2022, 41(6): 316-322. doi: 10.19509/j.cnki.dzkq.2022.0140MA Z D, MA L, LI K, et al. Multi-scale lithology recognition based on deep learning of rock images[J]. Bulletin of Geological Science and Technology, 2022, 41(6): 316-322. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2022.0140 [11] CHEN L C, ZHU Y K, PAPANDREOU G, et al. Encoder-decoder with atrous separable convolution for semantic image segmentation[C]//Anon. Proceedings of the European Conference on Computer Vision (ECCV). [S. l.]: [s. n.], 2018: 801-818. [12] LECUN Y, BENGIO Y, HINTON G. Deep learning[J]. Nature, 2015, 521: 436-444. doi: 10.1038/nature14539 [13] FU Y H, ALDRICH C. Froth image analysis by use of transfer learning and convolutional neural networks[J]. Minerals Engineering, 2018, 115: 68-78. doi: 10.1016/j.mineng.2017.10.005 [14] LORE K G, AKINTAYO A, SARKAR S. LLNet: A deep autoencoder approach to natural low-light image enhancement[J]. Pattern Recognition, 2017, 61: 650-662. doi: 10.1016/j.patcog.2016.06.008 [15] CAI J R, GU S H, ZHANG L. Learning a deep single image contrast enhancer from multi-exposure images[J]. IEEE Transactions on Image Processing, 2018, 27(4): 2049-2062. doi: 10.1109/TIP.2018.2794218 [16] KRIZHEVSKY A, SUTSKEVER I, HINTON G E. ImageNet classification with deep convolutional neural networks[J]. Communications of the ACM, 2017, 60(6): 84-90. doi: 10.1145/3065386 [17] 吕宪俊. 工艺矿物学[M]. 长沙: 中南大学出版社, 2011: 223-227.LÜ X J. Process mineralogy[M]. Changsha: Central South University Press, 2011: 223-227. (in Chinese) [18] EKE W I, ITUEN E, LIN Y H, et al. Laboratory evaluation of modified cashew nut shell liquid as oilfield wax inhibitors and flow improvers for waxy crude oils[J]. Upstream Oil and Gas Technology, 2022, 8: 100068. doi: 10.1016/j.upstre.2022.100068 [19] ZHENG Y W, ZHANG L X, CHEN S Z, et al. Robust decentralized stochastic gradient descent over unstable networks[J]. Computer Communications, 2023, 203: 163-179. doi: 10.1016/j.comcom.2023.02.025 -

下载:

下载: