-

摘要:

孕镶金刚石钻头广泛应用于各种硬岩钻进, 尤其是深部硬岩钻探钻井的工程实践活动中, 其碎岩机制表现为金属胎体包裹的金刚石出刃后压入、刻划和破碎岩石。金刚石钻头的磨损形式反映了孔底钻头-岩石的相互作用过程, 以及磨粒(包括岩屑、胎体碎屑和金刚石碎屑等)在孔底的存在状态, 它决定了金刚石钻头的钻进效率和使用寿命。目前关于孕镶金刚石钻头磨损理论、方法的研究大部分属于定性判断, 且常局限于区域特殊情况, 无法形成统一或可借鉴的实用指导体系。以地质钻探领域的孕镶金刚石钻头磨损相关研究文献为主, 讨论了孕镶金刚石钻头磨损的研究现状。首先结合地质钻探工业实践和行业规程归纳了钻头的非正常磨损类型, 然后从磨损图像、钻进信号2个方面介绍了钻头磨损评价方法, 从钻头整体、金刚石和金属胎体3个方面梳理了钻头钻进过程磨损机理与影响因素, 另外列举了主流的钻头磨损性能调控方法, 介绍了磨损分析方程的研究进展, 并探讨了机器学习方法如何辅助钻头磨损研究。孕镶金刚石钻头在深部硬岩钻探中有极大的潜力, 而其磨损性能是决定其最终使用效果的关键。为此, 对人工智能方法辅助数据分析、微观尺度计算模拟、增材制造和材料处理改性等研究方向进行了分析展望, 探索先进的金刚石钻头的磨损监测分析和调控方法, 以期满足地质深部钻探和地外星系钻探等远程监控钻进的需求。

Abstract:Significance Impregnated diamond bits (IDBs) have been widely used in various hard rock drilling activities, especially deep drilling. Drilling process with IDBs relies on diamond edge wrapped by metal matrices to break the rock formation, which means the wear pattern of the diamond bit reflects the interaction between bits and rock, as well as the existence form of broken particles, which directly determine the drilling efficiency and service life of the drilling tools. But up to now there have not been so much in-depth study on its wear mechanism and analysing method in geological drilling.

Progress and Analysis Therefore, this paper reviews the research literature on IDBs wear in the field of geological drilling, summarizes the abnormal bit wear problem according to engineering project experineces and industrial standards. Firstly, based on the experiences of geological drilling activities and industry standards, different types of abnormal bit wear of drill bits were summarized. Then, the evaluation methods of drill bit wear were introduced from the aspects of wear images and drilling signals. The wear mechanism and influencing factors of the drill bit in the drilling process were sorted out from three aspects: The overall drill bit, diamond, and metal matrix. In addition, mainstream methods of controlling drill bit wear performance were listed, and the research progress of wear analysis equations was introduced, besides, how machine learning methods can assist in the study of drill bit wear was discussed.

Conclusion and Prospect Thus, IDBs have great potentials in deep hard rock drilling, and their wear performance is the key influnencing the whole drilling activity. To this end, research directions such as artificial intelligence assisting data analysis, microscale computational simulation, additive manufacturing, and material processing modification were analyzed and discussed, aiming to explore advanced methods for monitoring, analyzing, and regulating the wear of diamond drill bits, so as to meet the needs of remote monitoring and controlling in drilling activities such as geological deep drilling and extraterrestrial drilling.

-

Key words:

- impregnated diamond bit /

- rock fracturing /

- bit wear /

- wear mechanism /

- wear evaluation /

- machine learning

-

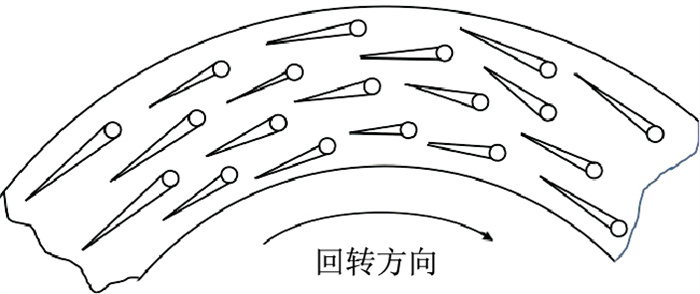

图 1 钻头唇面的正常磨损[7]

Figure 1. Normal wear of bit working surface

图 3 金刚石钻头唇面磨损的实验、评价和统计[19]

a. s=200 mm, m=50 min时的微观图像(二维数据); b. s=200 mm, m=50 min时的表面测量(三维数据); c. s=300 mm, m=75 min时的微观图像(二维数据); d. s=300 mm, m=75 min时的表面测量(三维数据); s.累计钻进深度; m.累计钻进时间

Figure 3. Experiment, evaluation and statistics of diamond bit working surface wear

图 5 深度学习卷积神经网络模型进行胎体磨损图像分割[27]

Figure 5. Wear image segmentation of matrices using a convolution neural network model based on deep learning

图 8 深度学习辅助孕镶金刚石钻头热损伤研究[89]

Figure 8. Deep learning enabled impregnated diamond bit thermal damage research

表 1 钻头磨损影响因素

Table 1. Influencing facters of bit wear

磨损影响因素 影响形式 钻头参数 金刚石参数 金刚石品级 金刚石出刃状态;钻头唇面-岩石间的间隙高度、接触面积; 钻头唇面的清洁、冷却状态; 钻头唇面宏观磨损形态 金刚石粒度 金刚石浓度 抗冲击韧性 胎体性能 胎体强度 胎体硬度 胎体耐磨性 胎体把持力 钻头结构 唇面形状 唇面尺寸 水口分布 水槽分布 地层性质 岩层参数 岩石类型 岩屑的颗粒级配、形貌等差异; 岩屑的组成矿物及研磨性 造岩矿物粒度 矿物胶结程度 岩石强度 岩石硬度 岩石研磨性 岩石裂隙度 岩层完整性 软硬夹层 地层环境 地层温度 钻头的工作温度、压力; 钻头的孔底清洁状态 地层压力 钻进参数 规程参数 钻压 钻头的孔底冷却状态 转速 泵量 介质参数 pH值 腐蚀磨损程度 电解质种类与浓度 -

[1] 吴燕平, 燕青芝. 金属结合剂金刚石工具研究进展[J]. 金刚石与磨料磨具工程, 2019, 39(2): 37-45. https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201902008.htmWU Y P, YAN Q Z. Research progress of metal bond diamond tools[J]. Diamond&Abrasives Engineering, 2019, 39(2): 37-45. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201902008.htm [2] 陶亚坤, 甘杰, 周燕, 等. 增材制造金刚石工具研究现状及展望[J]. 金刚石与磨料磨具工程, 2022, 42(5): 511-517. https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM202205001.htmTAO Y K, GAN J, ZHOU Y, et al. Research status and prospect of additive manufacturing diamond tools[J]. Diamond&Abrasives Engineering, 2022, 42(5): 511-517. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM202205001.htm [3] 徐西鹏, 黄辉, 胡中伟, 等. 磨粒工具的研究现状及发展趋势[J]. 机械工程学报, 2022, 58(15): 2-20. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202215002.htmXU X P, HUANG H, HU Z W, et al. Development of abrasive tools: State-of-the-art and prospectives[J]. Journal of Mechanical Engineering, 2022, 58(15): 2-20. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202215002.htm [4] 牛明远. 金刚石钻头钻进过程中摩擦磨损性能研究现状[J]. 河南建材, 2011(2): 40. https://www.cnki.com.cn/Article/CJFDTOTAL-HNJC201102028.htmNIU M Y. Research status of friction and wear properties of diamond bit during drilling activities[J]. Henan Building Materials, 2011(2): 40. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-HNJC201102028.htm [5] 杨文胜. 煤田地质勘探钻进中的金刚石钻头的磨损和钻具应用[J]. 技术与市场, 2019, 26(3): 148. https://www.cnki.com.cn/Article/CJFDTOTAL-JSYS201903076.htmYANG W S. Wear of diamond bit and application of drilling tool in coalfield geological exploration drilling[J]. Technology and Market, 2019, 26(3): 148. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JSYS201903076.htm [6] 杨新. 金刚石钻头性能优化中的一些热点研究问题[J]. 西部探矿工程, 2003, 15(12): 105-106. https://www.cnki.com.cn/Article/CJFDTOTAL-XBTK200312054.htmYANG X. Some hot research issues in diamond bit performance optimization[J]. West-China Exploration Engineering, 2003, 15(12): 105-106. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-XBTK200312054.htm [7] 王生福. 金刚石钻头非正常磨损和破坏形态的分析[J]. 探矿工程(岩土钻掘工程), 2007, 16(9): 95-96. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC200709029.htmWANG S F. Analysis of abnormal wear and failure patterns of diamond bit[J]. Drilling Engineering, 2007, 16(9): 95-96. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC200709029.htm [8] 赵强. 钻探施工中金刚石钻头的非正常磨损浅析[J]. 技术与市场, 2014, 21(11): 46. https://www.cnki.com.cn/Article/CJFDTOTAL-JSYS201411027.htmZHAO Q. Analysis of abnormal wear of diamond bit in drilling construction[J]. Technology and Market, 2014, 21(11): 46. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JSYS201411027.htm [9] 广东冶金地质勘探公司. 人造金刚石钻头磨损及变相[J]. 地质与勘探, 1977, 13(1): 76-77. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT197701020.htmMetallurgical Geological Exploration Company of Guangdong Province. Wear and phase change of synthetic diamond bit[J]. Geology and Exploration, 1977, 13(1): 76-77. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT197701020.htm [10] 冯国强. 金刚石钻头的非正常磨损与变形[J]. 勘探技术, 1978, 5(5): 8-13. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC197805002.htmFENG G Q. Abnormal wear and deformation of diamond bit[J]. Drilling Engineering, 1978, 5(5): 8-13. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC197805002.htm [11] 陕西省地质局探矿工程处. 岩心钻探金刚石钻头的非正常磨损[J]. 探矿工程, 1980, 7(1): 12-15. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC198001004.htmMining Engineering Office of Shaanxi Geological Bureau. Abnormal wear of diamond bit in core drilling[J]. Drilling Engineering, 1980, 7(1): 12-15. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC198001004.htm [12] 长江流域规划办公室三峡区勘测大队. 关于孕镶式金刚石钻头的磨损问题[J]. 水利水电技术, 1981, 12(5): 53-57. https://www.cnki.com.cn/Article/CJFDTOTAL-SJWJ198105012.htmThree Gorges Survey Brigade of the Yangtze River Basin Planning Office. Wear of impregnated diamond bit[J]. Water Resources and Hydropower Engineering, 1981, 12(5): 53-57. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-SJWJ198105012.htm [13] 时月超. 金刚石钻进的操作与钻头磨损形态分析[J]. 科技创业家, 2014, 5(1): 69. https://www.cnki.com.cn/Article/CJFDTOTAL-KEJI201401066.htmSHI Y C. Diamond drilling operation and bit wear pattern analysis[J]. Technological Pioneers, 2014, 5(1): 69. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-KEJI201401066.htm [14] 罗超, 李世忠, 李砚藻, 等. 人造金刚石孕镶钻头磨损特征的研究[J]. 地质与勘探, 1995, 31(2): 58-62. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT502.012.htmLUO C, LI S Z, LI Y Z, et al. Study on wear characteristics of synthetic diamond impregnated bit[J]. Geology and Exploration, 1995, 31(2): 58-62. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT502.012.htm [15] 鲁凡. 对孕镶金刚石钻头磨损规律的探讨: 钻头内径磨损常大于外径磨损的原因[J]. 中南工业大学学报, 1997, 28(6): 4-6. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD706.000.htmLU F. Discussion on the wear law of impregnated diamond bit: The reason why the wear of bit inner diameter is often greater than that of outer diameter[J]. Journal of Central South University Technology, 1997, 28(6): 4-6. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD706.000.htm [16] 刘银伟, 靖向党. 孕镶金刚石钻头工作层不均匀磨损原因的研究[J]. 探矿工程(岩土钻掘工程), 2005, 32(4): 56-58. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC20050400L.htmLIU Y W, JING X D. Research on the reason of uneven abrasion on the works layer of the impregnated diamond bit[J]. Drilling Engineering, 2005, 32(4): 56-58. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC20050400L.htm [17] ZHANG W. Development of new techniques for impregnated diamond coring bit wear measurement in conventional rotary drilling and vibration assisted rotary drilling[D]. St. John: Memorial University of Newfoundland, 2010. [18] 段隆臣, 汤凤林. 高转速钻进时金刚石钻头磨损的试验研究进展[J]. 地质科技情报, 2000, 20(1): 109-112. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ200001028.htmDUAN L C, TANG F L. Experimental research on the wear of diamond bit in high rpm drilling[J]. Geological Science and Technology Information, 2000, 20(1): 109-112. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ200001028.htm [19] PELLETIER S, DUFOER M. Characterization of wear and profile of diamond drill bit by optical profilometry[J]. Review of Scientific Instruments, 1994, 65(1): 208-211. doi: 10.1063/1.1144787 [20] MALEVICH N, MVLLER C, DREIER J, et al. Experimental and statistical analysis of the wear of diamond impregnated tools[J]. Wear, 2020, 468: 203574. [21] 石昆山. 孕镶人造金刚石钻头磨损机理的模拟试验研究[J]. 探矿工程, 1988, 15(5): 10-15. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC198805003.htmSHI K S. Simulation test study on wear mechanism of impregnated synthetic diamond bit[J]. Drilling Engineering, 1988, 15(5): 10-15. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC198805003.htm [22] WRIGHT D N, 史连君. 孕镶金刚石钻头唇面磨损的研究[J]. 国外地质勘探技术, 1991(8): 10-14. https://www.cnki.com.cn/Article/CJFDTOTAL-GWDK199108002.htmWRIGHT D N, SHI L J. Study on surface wear of impregnated diamond bit[J]. Foreign Geoexploration Technology, 1991(8): 10-14. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-GWDK199108002.htm [23] MILLER D, BALL A. The wear of diamonds in impregnated diamond bit drilling[J]. Wear, 1991, 141(2): 311-320. doi: 10.1016/0043-1648(91)90276-Z [24] 刘文川. 钎焊金刚石钻头的室内钻进与冲蚀磨损实验[D]. 北京: 中国地质大学(北京), 2016.LIU W C. The experimental study on drilling and erosion wear of the brazed diamond bit[D]. Beijing: China Unicersity of Geosciences (Beijing), 2016. (in Chinese with English abstract) [25] 张艺媛. 电镀金刚石钻头胎体性能及钻头钻进性能定量研究[D]. 武汉: 中国地质大学(武汉), 2018.ZHANG Y Y. Quantitative study on the matrix materials properties and drilling performances of electroplated diamond bit[D]. Wuhan: China University of Geosciences (Wuhan), 2018. (in Chinese with English abstract) [26] PENG L, PAN B, LIU Z, et al. Investigation on abrasion-corrosion properties of WC-based composite with fractal theory[J]. International Journal of Refractory Metals and Hard Materials, 2020, 87: 105142. doi: 10.1016/j.ijrmhm.2019.105142 [27] SUN W, GAO H, TAN S, et al. Wear detection of WC-Cu based impregnated diamond bit matrix based on SEM image and deep learning[J]. International Journal of Refractory Metals and Hard Materials, 2021, 98: 105530. doi: 10.1016/j.ijrmhm.2021.105530 [28] LAZAROVÁ E, KRULÁKOVÁ M, LABAŠ M, et al. Vibration signal for identification of concrete drilling process and drill bit wear[J]. Engineering Failure Analysis, 2020, 108: 104302. doi: 10.1016/j.engfailanal.2019.104302 [29] KRÚPA V, LAZAROVÁ E, IVANIĈOVÁ L, et al. Assessment of wear of diamond core drilling bits[C]//Anon. 2016 17th International Carpathian Control Conference (ICCC). [S. l. ]: [s. n. ], 2016: 396-400. [30] IVANIĈOVÁ L, LAZAROVÁ E, KRULÁKOVÁ M, et al. Indirect prediction of drill bit wear in andesite drilling[C]//Anon. 2018 19th International Carpathian Control Conference (ICCC). [S. l. ]: [s. n. ], 2018: 79-84. [31] KARAKUS M, MAY T, OLLERENSHAW D. Acoustic emission (AE) signatures of rock cutting response of an impregnated diamond drill bit[C]//Anon. World Congress on Engineering (WCE 2013). [S. l. ]: [s. n. ], 2013: 2068-2074. [32] KARAKUS M, PEREZ S. Acoustic emission analysis for rock-bit interactions in impregnated diamond core drilling[J]. International Journal of Rock Mechanics and Mining Sciences, 2014, 68: 36-43. doi: 10.1016/j.ijrmms.2014.02.009 [33] PEREZ S, KARKUS M, PELLET F. Development of a tool condition monitoring system for impregnated diamond bits in rock drilling applications[J]. Rock Mechanics and Rock Engineering, 2017, 50(5): 1289-1301. doi: 10.1007/s00603-016-1150-6 [34] 刘奕呈, 李玉梅, 张涛, 等. 基于CEEMDAN-CNN的钻头磨损状态监测研究[J]. 石油机械, 2022, 50(9): 59-65. https://www.cnki.com.cn/Article/CJFDTOTAL-SYJI202209008.htmLIU Y C, LI Y M, ZHANG T, et al. Monitoring of bit wear based on CEEMDAN-CNN[J]. China Petroleum Machinery, 2022, 50(9): 59-65. https://www.cnki.com.cn/Article/CJFDTOTAL-SYJI202209008.htm [35] 张祖培. 按金刚石钻头磨损机理对改进钻头设计的看法[J]. 探矿工程, 1982, 9(6): 7-9. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC198206002.htmZHANG Z P. Opinions on improving bit design according to wear mechanism of diamond bit[J]. Drilling Engineering, 1982, 9(6): 7-9. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC198206002.htm [36] TIAN X, TIAN S. The wear mechanisms of impregnated diamond bits[J]. Wear, 1994, 177(1): 81-91. doi: 10.1016/0043-1648(94)90120-1 [37] MONEIM M E A, ABDOU S. Comments on the wear mechanisms of impregnated diamond bits[J]. Wear, 1997, 205(1): 228-230. [38] GANT A J, KONYASHIN I, RIES B, et al. Wear mechanisms of diamond-containing hardmetals in comparison with diamond-based materials[J]. International Journal of Refractory Metals and Hard Materials, 2018, 71: 106-114. doi: 10.1016/j.ijrmhm.2017.10.013 [39] LIU W, GAO D L. Study on the anti-wear performance of diamond impregnated drill bits[J]. International Journal of Refractory Metals and Hard Materials, 2021, 99: 105577. doi: 10.1016/j.ijrmhm.2021.105577 [40] MOSTOFI M, RICHARD T, FRANCA L, et al. Wear response of impregnated diamond bits[J]. Wear, 2018, 410/411: 34-42. doi: 10.1016/j.wear.2018.04.010 [41] FRANCA L F P, MOSTOFI M, RICHARD T. Interface laws for impregnated diamond tools for a given state of wear[J]. International Journal of Rock Mechanics and Mining Sciences, 2015, 73: 184-193. doi: 10.1016/j.ijrmms.2014.09.010 [42] ХРИСТО М Х, 杨凯华. 金刚石钻头的磨损形式及其分类[J]. 地质科技情报, 1992, 11(3): 96-100. ХРИСТО М Х, https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ199203021.htmХРИСТО М Х, YANG K H. Wear forms and classification of diamond bits[J]. Geological Science and Technology Information, 1992, 11(3): 96-100. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ199203021.htm [43] RAO K, MISRA B. Wear of diamond grits of diamond core drills[J]. Indian Journal of Engineering and Materials Sciences, 1995, 2(1): 18-23. [44] 杨俊德. 金刚石钻头和金刚石锯片磨损机理、设计及性能测试研究[D]. 长沙: 中南大学, 2004.YANG J D. The study on wear regularity, design and performance test of diamond bit and diamond saw[D]. Changsha: Central South University, 2004. (in Chinese with English abstract) [45] 王殿江. 孕镶金刚石钻头胎体磨损的几何效应[J]. 地质与勘探, 1993, 29(8): 58-62. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT199308017.htmWANG D J. Geometric effect of matrix wear of impregnated diamond bit[J]. Geology and Exploration, 1993, 29(8): 58-62. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT199308017.htm [46] 杨俊德, 胡焕校. 金刚石钻头磨损机理分析[J]. 矿业研究与开发, 1997, 17(2): 37-39. https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK199702011.htmYANG J D, HU H X. Analysis of wearing mechanism of diamond bits[J]. Mining Research and Development, 1997, 17(2): 37-39. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK199702011.htm [47] 杨俊德, 杨洪武, 彭振斌. 钻进过程中金刚石钻头磨损规律试验研究[J]. 金刚石与磨料磨具工程, 2003, 23(5): 43-45. https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM200305010.htmYANG J D, YANG H W, PENG Z B. The experimental study on wear regularity of the impregnated bit of synthetic diamond[J]. Diamond&Abrasives Engineering, 2003, 23(5): 43-45. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM200305010.htm [48] 杨俊德, 彭振斌, 陈石林, 等. 金刚石钻头钻进过程中金刚石磨损规律试验研究[J]. 矿冶工程, 2003, 23(4): 64-66. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC200304020.htmYANG J D, PENG Z B, CHEN S L, et al. Experimental study on the wear regularity of diamond in impregnated bits in drilling[J]. Mining and Metallurgical Engineering, 2003, 23(4): 64-66. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC200304020.htm [49] LUO S Y. Investigation of the worn surfaces of diamond sawblades in sawing granite[J]. Journal of Materials Processing Technology, 1997, 70(1): 1-8. [50] 叶赟. 孕镶钎焊金刚石钻头的磨损试验及其切削过程的数值仿真[D]. 北京: 中国地质大学(北京), 2010.YE Y. The wear experiment and cutting simulation of impregnated brazed diamond bit[D]. Beijing: China University of Geosciences (Beijing), 2010. (in Chinese with English abstract) [51] 徐城凯. 孕镶金刚石钻头磨损规律及模型研究[D]. 山东青岛: 中国石油大学(华东), 2018.XU C K. Research on the wear regularity and model of impregnated diamond bits[D]. Qingdao Shangdong: China University of Petroleum (East China), 2018. (in Chinese with English abstract) [52] GÜYAGÜLER T, ERSAYIN S, BILGEN S, et al. A critical review of factors influencing the wear of thermally stable diamond (tsd) rock drilling bits[M]. Kızılay, Ankara: TMMOB Maden Mühendisleri Odası, 1997. [53] 曲飞龙, 张绍和, 王佳亮. 适用于栅格状孕镶金刚石钻头的胎体配方研究[J]. 煤田地质与勘探, 2018, 46(1): 170-175. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201801029.htmQU F L, ZHANG S H, WANG J L. Matrix formula for impregnated diamond bit with grids[J]. Coal Geology&Exploration, 2018, 46(1): 170-175. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201801029.htm [54] 雷威威. 硬质砂岩对孕镶钻头磨损实验研究[D]. 山东青岛: 中国石油大学(华东), 2016.LEI W W. Experimental study on impregnated bit wear by hard sandstone[D]. Qingdao Shangdong: China University of Petroleum (East China), 2016. (in Chinese with English abstract) [55] 程钟寿. 人造金刚石聚晶地质岩心钻头钻岩效果[J]. 矿产与地质, 1995, 9(增刊1): 426-430. https://www.cnki.com.cn/Article/CJFDTOTAL-KCYD5S1.043.htmCHENG Z S. Drilling effect of synthetic diamond polycrystalline geological core bit[J]. Mineral Resources and Geology, 1995, 9(S1): 426-430. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-KCYD5S1.043.htm [56] 汤凤林, ЧИХОТКИН В Ф, 段隆臣, 等. 机械钻速与金刚石底出刃、钻进规程参数关系的试验研究[J]. 探矿工程(岩土钻掘工程), 2019, 46(12): 73-79. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC201912014.htmTANG F L, CHIKHOTKIN V F, DUAN L C, et al. Experimental research on dependence of penetration rate on diamond exposure at bit face and drilling parameters[J]. Drilling Engineering, 2019, 46(12): 73-79. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC201912014.htm [57] 郑玉琢. 孕镶金刚石钻头胎体磨损因素[J]. 地质与勘探, 1988, 24(8): 60-63. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT198808013.htmZHENG Y Z. Wear factors of impregnated diamond bit matrix[J]. Geology and Exploration, 1988, 24(8): 60-63. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT198808013.htm [58] 陈岳承. 金刚石钻头在裂隙岩层中钻进的磨损特点和规律[J]. 西部探矿工程, 1994, 6(6): 67-68. https://www.cnki.com.cn/Article/CJFDTOTAL-XBTK406.025.htmCHEN Y C. Wear characteristics and rules of diamond bit drilling in fractured rock[J]. West-China Exploration Engineering, 1994, 6(6): 67-68. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-XBTK406.025.htm [59] 马瑶, 赵江南. 机器学习方法在矿产资源定量预测应用研究进展[J]. 地质科技通报, 2021, 40(1): 132-141. doi: 10.19509/j.cnki.dzkq.2021.0108MA Y, ZHAO J N. Advances in the application of machine learning methods in mineral prospectivity mapping[J]. Bulletin of Geological Science and Technology, 2021, 40(1): 132-141. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2021.0108 [60] 黄发明, 胡松雁, 闫学涯, 等. 基于机器学习的滑坡易发性预测建模及其主控因子识别[J]. 地质科技通报, 2022, 41(2): 79-90. doi: 10.19509/j.cnki.dzkq.2021.0087HUANG F M, HU S Y, YAN X Y, et al. Landslide susceptibility prediction and identification of its main environmental factors based on machine learning models[J]. Bulletin of Geological Science and Technology, 2022, 41(2): 79-90. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2021.0087 [61] 马泽栋, 马雷, 李科, 等. 基于岩石图像深度学习的多尺度岩性识别[J]. 地质科技通报, 2022, 41(6): 316-322. doi: 10.19509/j.cnki.dzkq.2022.0140MA Z D, MA L, LI K, et al. Multi-scale lithology recognition based on deep learning of rock images[J]. Bulletin of Geological Science and Technology, 2022, 41(6): 316-322. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2022.0140 [62] 谭刚. 高胎体孕镶金刚石钻头试验研究[D]. 北京: 中国地质大学(北京), 2010.TAN G. The experimental study on high-matrix impregnated diamond bit[D]. Beijing: China University of Geosciences (Beijing), 2010. (in Chinese with English abstract) [63] 徐良. 硬岩钻进用仿生耦合金刚石取心钻头研究[D]. 长春: 吉林大学, 2009.XU L. Research on bionic coupling diamond coring bits in drilling hard rock[D]. Changchun: Jilin University, 2009. (in Chinese with English abstract) [64] 向琦. 火成岩地层孕镶金刚石钻头磨损机理[D]. 黑龙江大庆: 东北石油大学, 2014.XIANG Q. The wear mechanism of impregnated diamond bit in igneous rock formation[D]. Daqing Heilongjiang: Northeast Petroleum University, 2014. (in Chinese with English abstract) [65] LI S B, XIANG Q, ZHANG L G. The wear mechanisms of diamond impregnated bit matrix[C]//LI J. Machinery Electronics and Control Engineering Ⅲ. Switzerland: Trans Tech Publications LTD, 2014, 441: 15-18. [66] TAN S, LI C, FANG X, et al. Investigation of filling phase percentages on the performance of WC-Cu based hot-pressing diamond bit matrices[J]. Metals, 2019, 9(12): 1305. doi: 10.3390/met9121305 [67] ABTAHI A. Bit wear analysis and optimization for vibration assisted rotary drilling (VARD) using impregnated diamond bits[D]. St. John: Memorial University of Newfoundland, 2011. [68] 孙祺斌. 特高胎体多层水口孕镶金刚石钻头设计与仿真研究[D]. 北京: 中国地质大学(北京), 2021.SUN Q B. Design and numerical simulation of multi-layer bit with extra-high matrix[D]. Beijing: China University of Geosciences (Beijing), 2021. (in Chinese with English abstract) [69] 黄子伦. 岩土钻掘用高胎体仿生钻头的试验研究[D]. 长春: 吉林大学, 2019.HUANG Z L. Experiment of high matrix bionics bit for rock and soil drilling[D]. Changchun: Jilin University, 2019. (in Chinese with English abstract) [70] 王光祖, 崔仲鸣. 化学气相沉积金刚石膜的工程应用[J]. 超硬材料工程, 2020, 32(1): 37-41. https://www.cnki.com.cn/Article/CJFDTOTAL-ZBKJ202001013.htmWANG G Z, CUI Z M. Functional application of diamond film[J]. Superhard Material Engineering, 2020, 32(1): 37-41. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-ZBKJ202001013.htm [71] ZAITSEV A A, SIDORENKO D A, LEVASHOV E A, et al. Diamond tools in metal bonds dispersion-strengthened with nanosized particles for cutting highly reinforced concrete[J]. Journal of Superhard Materials, 2010, 32(6): 423-431. doi: 10.3103/S1063457610060080 [72] 常思. 金刚石钻头胎体材料力学性能的多元纳米强化研究[D]. 长春: 吉林大学, 2022.CHANG S. Investigation of hybrid nano-strengthening on mechanical properties of diamond drill bit matrix[D]. Changchun: Jilin University, 2022. (in Chinese with English abstract) [73] 李梦. 无硬质相胎体仿生异型齿孕镶金刚石钻头研究[D]. 长春: 吉林大学, 2017.LI M. Research on no-hardphase-matrix impregnated diamond bit with bionic abnormal shape[D]. Changchun: Jilin University, 2017. (in Chinese with English abstract) [74] 吕仲林, 申登举. Cu-Al2O3作金刚石钻头胎体的应用研究[J]. 粉末冶金工业, 2018, 28(1): 50-55. https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201801016.htmLÜ Z L, SHEN D J. Study on the application of Cu-Al2O3 as matrix of diamond bit[J]. Powder Metallurgy Industry, 2018, 28(1): 50-55. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201801016.htm [75] 王佳亮, 韦文杰, 张绍和, 等. 硬脆性辅料对孕镶金刚石钻头钻进性能的影响机制[J]. 煤田地质与勘探, 2019, 47(1): 200-205. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201901031.htmWANG J L, WEI W J, ZHANG S H, et al. Influence mechanism of hard brittle abrasive on the drilling performance of impregnated diamond bit[J]. Coal Geology&Exploration, 2019, 47(1): 200-205. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201901031.htm [76] 陈西. 打滑地层孕镶金刚石钻头胎体研制[D]. 北京: 中国地质大学(北京), 2021.CHEN X. Development of the matrix of impregnated diamond bit in slippery formation[D]. Beijing: China University of Geosciences (Beijing), 2021. (in Chinese with English abstract) [77] 高玉彬, 陈洋. 钻进坚硬致密岩层的金刚石钻头试验研究[J]. 超硬材料工程, 2021, 33(3): 1-6. https://www.cnki.com.cn/Article/CJFDTOTAL-ZBKJ202103001.htmGAO Y B, CHEN Y. Experimental study of diamond bit for drilling hard and compact rock[J]. Superhard Material Engineering, 2021, 33(3): 1-6. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-ZBKJ202103001.htm [78] 罗爱云, 王伟雄, 段隆臣. 强、弱混镶新型金刚石钻头的研究[J]. 金刚石与磨料磨具工程, 2003, 23(2): 48-50. https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM200302015.htmLUO A Y, WANG W X, DUAN L C. Development of a new type of diamond bit by mix-holding technique[J]. Diamond&Abrasives Engineering, 2003, 23(2): 48-50. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM200302015.htm [79] 高科, 陈杭凯, 许晓慧, 等. 双孕镶金刚石钻头的自平衡逆向回转破岩性能[J]. 吉林大学学报(工学版), 2021, 51(3): 866-874. https://www.cnki.com.cn/Article/CJFDTOTAL-JLGY202103010.htmGAO K, CHEN H K, XU X H, et al. Rock fragmentation characteristics of double impregnated diamond bits with self-balancing reverse rotation[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(3): 866-874. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JLGY202103010.htm [80] 王照智. 仿生耦合孕镶金刚石钻头耐磨增效机理研究[D]. 长春: 吉林大学, 2017.WANG Z Z. Study on the mechanism of wear resistance and efficiency increase of bionic coupling impregnated diamond bit[D]. Changchun: Jilin University, 2017. (in Chinese with English abstract) [81] 孙友宏, 高科. 仿生耦合理论及爪趾型仿生金刚石钻头的应用[C]//佚名. 第十八届全国探矿工程(岩土钻掘工程)技术学术交流年会论文集. 哈尔滨: 中国地质学会探矿工程专业委员会, 2015: 696-700.SUN Y H, GAO K. Bionic coupling theory and application of claw-toe bionic diamond bit[C]//Anon. Proceedings of the 18th Annual Conference of National Exploration Engineering (Geotechnical Drilling Engineering) Technical Academic Exchange. Harbin: Prospecting Engineering Professional Committee of the Chinese Geological Society, 2015: 696-700. (in Chinese with English abstract) [82] 潘秉锁, 方小红, 杨凯华. 自润滑孕镶金刚石钻头胎体材料初步研究[J]. 探矿工程(岩土钻掘工程), 2009, 36(1): 76-78. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC200901031.htmPAN B S, FANG X H, YANG K H. Elementary study on self-lubricating matrix material for impregnated diamond bit[J]. Drilling Engineering, 2009, 36(1): 76-78. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC200901031.htm [83] TAN S, ZHANG W, DUAN L, et al. Effects of MoS2 and WS2 on the matrix performance of WC based impregnated diamond bit[J]. Tribology International, 2019, 131: 174-183. doi: 10.1016/j.triboint.2018.10.038 [84] 史晓亮. 金刚石-硬质合金复合齿及其钻头的研究[D]. 武汉: 中国地质大学(武汉), 2003.SHI X L. Research on diamond enhanced tungsten carbide composite button and its bits[D]. Wuhan: China University of Geosciences (Wuhan), 2003. (in Chinese with English abstract) [85] WU Y, YAN Q, ZHANG X. Wear characteristics of Fe-based diamond composites with cerium oxide (CeO2) reinforcements[J]. International Journal of Refractory Metals and Hard Materials, 2020, 86: 105093. doi: 10.1016/j.ijrmhm.2019.105093 [86] 汤凤林, А. И. 拉姆宾. 关于金刚石钻头绝对磨损和相对磨损的试验研究[J]. 地球科学(武汉地质学院学报), 1987, 12(1): 93-101. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX198701014.htmTANG F L, LAMBIN А И. The experimental research on absolute and relative wear of impregnated diamond bit[J]. Earth Science (Journal of Wuhan College of Geology), 1987, 12(1): 93-101. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX198701014.htm [87] SLNOR A, WARREN T M. Drag bit wear model[J]. SPE Drilling Engineering, 1989, 4(2): 128-136. doi: 10.2118/16699-PA [88] NAGANAWA S. Feasibility study on roller-cone bit wear detection from axial bit vibration[J]. Journal of Petroleum Science and Engineering, 2012, 82: 140-150. [89] BOTTI L, MORA C, ANTONUCCI A, et al. Carbide-tipped bit wear patterns and productivity with concrete drilling[J]. Wear, 2017, 386: 58-62. [90] 张野, 陈金桥, 李炎隆. 基于多深度模型的钻孔结构面智能识别与量化分析[J]. 地质科技通报, 2023, 42(6): 31-41. doi: 10.19509/j.cnki.dzkq.tb20220091ZHANG Y, CHEN J Q, LI Y L. Intelligence recognition and quantitative analysis of borehole hydraulic geological images utilizing multiple deep learning models[J]. Bulletin of Geological Science and Technology, 2023, 42(6): 31-41. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.tb20220091 [91] 张驰, 潘懋, 胡水清, 等. 融合储层纵向信息的机器学习岩性识别方法[J]. 地质科技通报, 2023, 42(3): 289-299. doi: 10.19509/j.cnki.dzkq.tb20220289ZHANG C, PAN M, HU S Q, et al. A machine learning lithologic identification method combined with vertical reservoir information[J]. Bulletin of Geological Science and Technology, 2023, 42(3): 289-299. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.tb20220289 [92] WANG L Q, SHAO M J, ZHANG W, et al. Prediction and analysis of PDC bit wear in conglomerate layer with machine learning and finite-element method[J]. Geofluids, 2022, 2022: 4324202. [93] RAFEZI H, HASSANI F. Drill bit wear monitoring and failure prediction for mining automation[J]. International Journal of Mining Science and Technology, 2023, 33(3): 289-296. doi: 10.1016/j.ijmst.2022.10.006 [94] SUN W C, GAO H, CHEN Y X, et al. Thermal failure of diamond tools indicated by diamond degradation: Damage evaluation and property prediction on small image datasets[J]. Engineering Applications of Artificial Intelligence, 2023, 119: 105800. doi: 10.1016/j.engappai.2022.105800 -

下载:

下载: