A prediction model of the joint roughness coefficient based on Gaussian process regression

-

摘要:

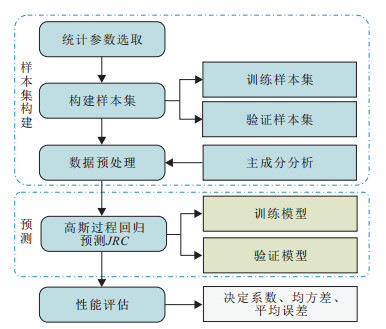

岩体结构面粗糙度系数(

JRC )的估算是岩体力学性质评价的重要环节, 由于单一统计参数法难以全面表征岩体结构面的复杂粗糙形貌, 单一统计参数法建立的JRC 计算模型精度较低。选取表征结构面粗糙形态的8种统计参数, 结合主成分分析法(PCA)和高斯过程回归(GPR)算法, 构建基于多参数融合的JRC 预测模型。以公开的112条岩体结构面剖面线数据集(其中95条作为训练样本, 17条为验证样本)为例进行分析研究, 最后将预测所得JRC 与实测值对比并分析预测效果。结果表明: 由高斯过程回归构建的JRC 预测模型决定系数(R 2)高达0.972, 均方根误差(MSE )为0.517, 反映出高斯过程回归方法在小样本条件下构建多统计参数与JRC 值隐式关系的适用性, 为今后人工智能在JRC 指标预测方面实现合理预测提供了思路。Abstract:Objective Estimating the joint roughness coefficient (JRC) is essential for evaluating the mechanical properties of a rock mass. Due to the limitation of a single statistical parameter for characterizing morphology, JRC values estimation by a single statistical parameter may produce a sufficiently unreliable result.

Methods To address the existing challenges in determining JRC values, a model based on Gaussian process regression (GPR) combined with principal component analysis (PCA) was proposed for the quantitative evaluation of JRC. Notably, eight parameters were selected as indicators for the comprehensive expression of the rock joint roughness. To analyse the model's performance, a publicly available dataset of 112 rock joint profiles was used as an example, of which 95 were chosen as training samples and 17 were chosen as validation samples. The reliability of the model was verified by comparing the predicted results with the measured JRC values.

Results The results show that the derived GPR model demonstrates promising performance (

R 2=0.972,MSE =0.517) for estimation of JRC values, indicating the high applicability of the model in constructing implicit relationships between multiple statistical parameters and JRC values even under small sample conditions.Conclusion In general, the GPR model may provide a new way of estimating JRC values with artificial intelligence.

-

Key words:

- rock joints /

- roughness /

- Gaussian process regression /

- statistical parameter /

- prediction

-

表 1 形貌指标的统计学特征

Table 1. Statistical features of these morphological indicators

参数 均值 最大值 最小值 标准差 Rave 0.006 9 0.036 0 0.001 1 0.005 8 SDh/mm 0.453 0 2.585 5 0.076 4 0.405 5 iave/(°) 10.306 4 27.861 0 3.104 2 4.223 0 SDi/(°) 16.867 3 40.323 1 5.159 1 6.166 0 Rmax 0.033 9 0.165 3 0.006 6 0.027 0 Rp 1.032 6 1.181 3 1.002 8 0.029 6 SF/mm2 0.011 4 0.072 6 0.000 9 0.011 7 Z2 0.248 0 0.675 0 0.074 6 0.101 0 Rave, Rmax.分别为平均和最大相对起伏高度;SDh.起伏高度标准差;iave.平均起伏角;SDi.起伏角标准差;Rp.剖面线粗糙系数;SF.结构函数;Z2.坡度均方根参数;下同 -

[1] 唐辉明. 工程地质学基础[M]. 北京: 化学工业出版社, 2008.TANG H M. Fundamentals of engineering geology[M]. Beijing: Chemical Industry Press, 2008. (in Chinese with English abstract) [2] ZHANG X B, JIANG Q H, CHEN N, et al. Laboratory investigation on shear behavior of rock joints and a new peak shear strength criterion[J]. Rock Mechanics and Rock Engineering, 2016, 49(9): 3495-3512. doi: 10.1007/s00603-016-1012-2 [3] 唐雅婷, 谭杰, 李长冬, 等. 基于模型试验的动水驱动型顺层岩质滑坡启滑机制初探[J]. 地质科技通报, 2022, 41(6): 137-148. doi: 10.19509/j.cnki.dzkq.2022.0202TANG Y T, TAN J, LI C D, et al. Preliminary study on the initiation mechanism of hydrodynamic-driven bedding rock landslides based on physical model tests[J]. Bulletin of Geological Science and Technology, 2022, 41(6): 137-148. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2022.0202 [4] 谢妮, 王丁浩, 吕阳, 等. 酸腐蚀作用下川渝红层砂岩蠕变特性试验研究[J]. 地质科技通报, 2022, 41(5): 141-149. doi: 10.19509/j.cnki.dzkq.2022.0142XIE N, WANG D H, LÜ Y, et al. Experimental study on creep behaviors of red sandstone in Sichuan and Chongqing under acid corrosion[J]. Bulletin of Geological Science and Technology, 2022, 41(5): 141-149. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2022.0142 [5] LIU Q S, TIAN Y C, LIU D F, et al. Updates to JRC-JCS model for estimating the peak shear strength of rock joints based on quantified surface description[J]. Engineering Geology, 2017, 228: 282-300. doi: 10.1016/j.enggeo.2017.08.020 [6] SINGH H K, BASU A. Evaluation of existing criteria in estimating shear strength of natural rock discontinuities[J]. Engineering Geology, 2018, 232: 171-181. doi: 10.1016/j.enggeo.2017.11.023 [7] 宋磊博, 亢倩倩, 杜时贵, 等. 基于表面微凸体磨损特征演化规律的节理剪切强度各向异性机制研究[J]. 岩土力学, 2021, 42(9): 2331-2343. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202109002.htmSONG L B, KANG Q Q, DU S G, et al. Anisotropy mechanism of shear strength based on wear and shear failure evolution of asperities of joint surface[J]. Rock and Soil Mechanics, 2021, 42(9): 2331-2343. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202109002.htm [8] 杨超, 蒋淏南, 岳六一, 等. 法向卸荷条件下非贯通节理岩体剪切力学特性试验研究[J]. 岩土工程学报, 2022, 44(9): 1741-1750. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202209020.htmYANG C, JIANG H N, YUE L Y, et al. Shear mechanical properties of rock mass with discontinuous joints under unloading normal stress[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(9): 1741-1750. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202209020.htm [9] BARTON N, CHOUBEY V. The shear strength of rock joints in theory and practice[J]. Rock Mechanics, 1977, 10(1): 1-54. [10] BARTON N. Review of a new shear-strength criterion for rock joints[J]. Engineering Geology, 1973, 7(4): 287-332. doi: 10.1016/0013-7952(73)90013-6 [11] 肖维民, 刘伟超, 朱占元. 基于正反向直剪试验的岩石节理JRC值计算研究[J]. 岩石力学与工程学报, 2021, 40(增刊2): 3098-3106. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2021S2010.htmXIAO W M, LIU W C, ZHU Z Y. Study on calculation of rock joint JRC value based on forward and reverse direct shear tests[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(S2): 3098-3106. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2021S2010.htm [12] LEE S D, LEE C I, PARK Y. Characterization of joint profiles and their roughness parameters[J]. International Journal of Rock Mechanics and Mining Sciences, 1997, 34(3/4): 174.e1-174.e5. [13] TANG Z C, JIAO Y Y, WONG L N Y, et al. Choosing appropriate parameters for developing empirical shear strength criterion of rock joint: Review and new insights[J]. Rock Mechanics and Rock Engineering, 2016, 49(11): 4479-4490. doi: 10.1007/s00603-016-1014-0 [14] GE Y F, KULATILAKE P H S W, TANG H M, et al. Investigation of natural rock joint roughness[J]. Computers and Geotechnics, 2014, 55: 290-305. doi: 10.1016/j.compgeo.2013.09.015 [15] 杜时贵, 黄曼, 罗战友, 等. 岩石结构面力学原型试验相似材料研究[J]. 岩石力学与工程学报, 2010, 29(11): 2263-2270. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201011014.htmDU S G, HUANG M, LUO Z Y, et al. Similar material study of mechanical prototype test of rock structural plane[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(11): 2263-2270. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201011014.htm [16] 范斌强. 基于精细雕刻的岩体结构面峰值抗剪强度模型及工程应用研究[D]. 武汉: 中国地质大学(武汉), 2021.FAN B Q. Research on the peak shear strength model of rock joint based on fine carving and its engineering application[D]. Wuhan: China University of Geosciences (Wuhan), 2021. (in Chinese with English abstract) [17] TSE R, CRUDEN D M. Estimating joint roughness coefficients[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1979, 16(5): 303-307. [18] YANG Z Y, LO S C, DI C C. Reassessing the joint roughness coefficient (JRC) estimation using Z2[J]. Rock Mechanics and Rock Engineering, 2001, 34(3): 243-251. doi: 10.1007/s006030170012 [19] SAYLES R S, THOMAS T R. The spatial representation of surface roughness by means of the structure function: A practical alternative to correlation[J]. Wear, 1977, 42(2): 263-276. doi: 10.1016/0043-1648(77)90057-6 [20] ZHANG G C, KARAKUS M, TANG H M, et al. A new method estimating the 2D joint roughness coefficient for discontinuity surfaces in rock masses[J]. International Journal of Rock Mechanics and Mining Sciences, 2014, 72: 191-198. doi: 10.1016/j.ijrmms.2014.09.009 [21] YU X B, VAYSSADE B. Joint profiles and their roughness parameters[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1991, 28(4): 333-336. [22] MAERZ N H, FRANKLIN J A, BENNETT C P. Joint roughness measurement using shadow profilometry[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1990, 27(5): 329-343. [23] 陈世江, 赵自豪, 王超. 基于修正线粗糙度法的岩石节理粗糙度估值[J]. 金属矿山, 2012(6): 22-25. doi: 10.3969/j.issn.1001-1250.2012.06.007CHEN S J, ZHAO Z H, WANG C. Estimation of rock joint roughness based on modified line-roughness[J]. Metal Mine, 2012(6): 22-25. (in Chinese with English abstract) doi: 10.3969/j.issn.1001-1250.2012.06.007 [24] 李化, 黄润秋. 岩石结构面粗糙度系数JRC定量确定方法研究[J]. 岩石力学与工程学报, 2014, 33(增刊2): 3489-3497. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2014S2013.htmLI H, HUANG R Q. Method of quantitative determination of joint roughness coefficient[J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(S2): 3489-3497. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2014S2013.htm [25] 蔡毅, 唐辉明, 葛云峰, 等. 岩体结构面三维粗糙度评价的新方法[J]. 岩石力学与工程学报, 2017, 36(5): 1101-1110. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201705006.htmCAI Y, TANG H M, GE Y F, et al. A new method for evaluating the roughness of three-dimensional discontinuity surface of rock[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(5): 1101-1110. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201705006.htm [26] HONG E S, LEE J S, LEE I M. Underestimation of roughness in rough rock joints[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2008, 32(11): 1385-1403. doi: 10.1002/nag.678 [27] 陈世江, 朱万成, 王创业, 等. 岩体结构面粗糙度系数定量表征研究进展[J]. 力学学报, 2017, 49(2): 239-256. https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB201702001.htmCHEN S J, ZHU W C, WANG C Y, et al. Review of research progresses of the quantifying joint roughness coefficient[J]. Chinese Journal of Theoretical and Applied Mechanics, 2017, 49(2): 239-256. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB201702001.htm [28] 马泽栋, 马雷, 李科, 等. 基于岩石图像深度学习的多尺度岩性识别[J]. 地质科技通报, 2022, 41(6): 316-322. doi: 10.19509/j.cnki.dzkq.2022.0140MA Z D, MA L, LI K, et al. Multi-scale lithology recognition based on deep learning of rock images[J]. Bulletin of Geological Science and Technology, 2022, 41(6): 316-322. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2022.0140 [29] 宋琨, 孙驰, 安冬, 等. 数字钻孔全景影像中结构面特征智能识别方法[J]. 地质科技通报, 2020, 39(5): 17-22. doi: 10.19509/j.cnki.dzkq.2020.0503SONG K, SUN C, AN D, et al. Intelligent identification method for rock discontinuities properties by digital borehole panoramic images[J]. Bulletin of Geological Science and Technology, 2020, 39(5): 17-22. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2020.0503 [30] 宋康明, 姜阳厚, 谭志祥, 等. 基于随机森林方法的岩石节理粗糙度系数研究[J]. 地质科技情报, 2018, 37(3): 263-267. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201803035.htmSONG K M, JIANG Y H, TAN Z X, et al. Method to calculate the joint roughness coefficient based on random forest[J]. Geological Science and Technology Information, 2018, 37(3): 263-267. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201803035.htm [31] WANG L Q, WANG C S, KHOSHNEVISAN S, et al. Determination of two-dimensional joint roughness coefficient using support vector regression and factor analysis[J]. Engineering Geology, 2017, 231: 238-251. doi: 10.1016/j.enggeo.2017.09.010 [32] 苗发盛, 吴益平, 李麟玮, 等. 基于Boosting-决策树C5.0的岩体结构面粗糙度预测[J]. 浙江大学学报(工学版), 2021, 55(3): 483-490. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC202103008.htmMIAO F S, WU Y P, LI L W, et al. Prediction of joint roughness coefficient of rock mass based on boosting-decision tree C5.0[J]. Journal of Zhejiang University (Engineering Science Edition), 2021, 55(3): 483-490(in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC202103008.htm [33] 尹宏, 王述红, 董卓然, 等. 引入因子分析的结构面粗糙度RBF复合参数模型[J]. 岩土工程学报, 2022, 44(4): 721-730. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202204015.htmYIN H, WANG S H, DONG Z R, et al. RBF composite parameter model for structural surface roughness with factor analysis[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(4): 721-730. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202204015.htm [34] RASMUSSEN C E, WILLIAMS C K I. Gaussian processes for machine learning[M]. Cambridge, Mass. : MIT Press, 2006. [35] 赵腾远, 宋超, 何欢. 小样本条件下江苏软土路基回弹模量的贝叶斯估计: 基于静力触探数据与高斯过程回归的建模分析[J]. 岩土工程学报, 2021, 43(增刊2): 137-141. doi: 10.11779/CJGE2021S2033ZHAO T Y, SONG C, HE H. Bayesian estimation of resilient modulus of Jiangsu soft soils from sparse dat: Gaussian process regression and cone penetration test data-based modelling and analysis[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(S2): 137-141. (in Chinese with English abstract) doi: 10.11779/CJGE2021S2033 [36] 宋超, 赵腾远, 许领. 基于贝叶斯高斯过程回归与模型选择的岩石单轴抗压强度估计方法[J]. 岩土工程学报, 2023, 45(8): 1664-1673. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202308013.htmSONG C, ZHAO T Y, XU L. Estimation of uniaxial compressive strength based on fully Bayesian Gaussian process regression and model class selection[J]. Chinese Journal of Geotechnical Engineering, 2023, 45(8): 1664-1673. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202308013.htm [37] GRASSELLI G. Shear strength of rock joints based on quantified surface description[C]//OHNISHI Y, AOKI K. ISRM International Symposium/3rd Asian Rock Mechanics Symposium (ARMS). Rotterdam, Netherlands: Millpress Science Publisherspo Box, 2001. [38] BANDIS S C, LUMSDEN A C, BARTON N R. Fundamentals of rock joint deformation[J]. International Journal of Rock Mechanics and Mining Sciences, 1983, 20(6): 249-268. doi: 10.1016/0148-9062(83)90595-8 [39] STAVROS B. Experimental studies of scale effects on shear strength, and deformation of rock joints[D]. Leeds, Yorkshire and the Humber, UK: University of Leeds, 1980. [40] YANG Z Y, DI C C, YEN K C. The effect of asperity order on the roughness of rock joints[J]. International Journal of Rock Mechanics and Mining Sciences, 2001, 38(5): 745-752. doi: 10.1016/S1365-1609(01)00032-6 [41] GENTIER S, RISS J, ARCHAMBAULT G, et al. Influence of fracture geometry on shear behavior[J]. International Journal of Rock Mechanics and Mining Sciences, 2000, 37(12): 161-174. [42] 董福瑞, 王述红, 侯钦宽. 基于主成分分析的多参数岩体结构面优势分组方法研究[J]. 岩土力学, 2022, 43(9): 2457-2470. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202209012.htmDONG F R, WANG S H, HOU Q K. Multi-parameter dominant grouping method of rock mass discontinuity based on principal component analysis[J]. Rock and Soil Mechanics, 2022, 43(9): 2457-2470. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202209012.htm [43] HAN L, WANG L, DING X M, et al. Similarity quantification of soil parametric data and sites using confidence ellipses[J]. Geoscience Frontiers, 2022, 13(1): 101280. doi: 10.1016/j.gsf.2021.101280 [44] 陈朝亮, 彭树宏, 钱静, 等. 基于AHP-Logistic熵权模型的西南浅丘区地质灾害分布特征研究: 以内江市为例[J]. 长江科学院院报, 2020, 37(2): 55-61. https://www.cnki.com.cn/Article/CJFDTOTAL-CJKB202002012.htmCHEN C L, PENG S H, QIAN J, et al. Distribution characteristics of geological hazards in southwestern shallow hill based on AHP-Logistic entropy combined weight model: A case study of Neijiang city[J]. Journal of Yangtze River Scientific Research Institute, 2020, 37(2): 55-61. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-CJKB202002012.htm -

下载:

下载: