Three-stage, three-category, three-dimensional characterization and evaluation of CO2 enhanced oil recovery and geological carbon storage

-

摘要:

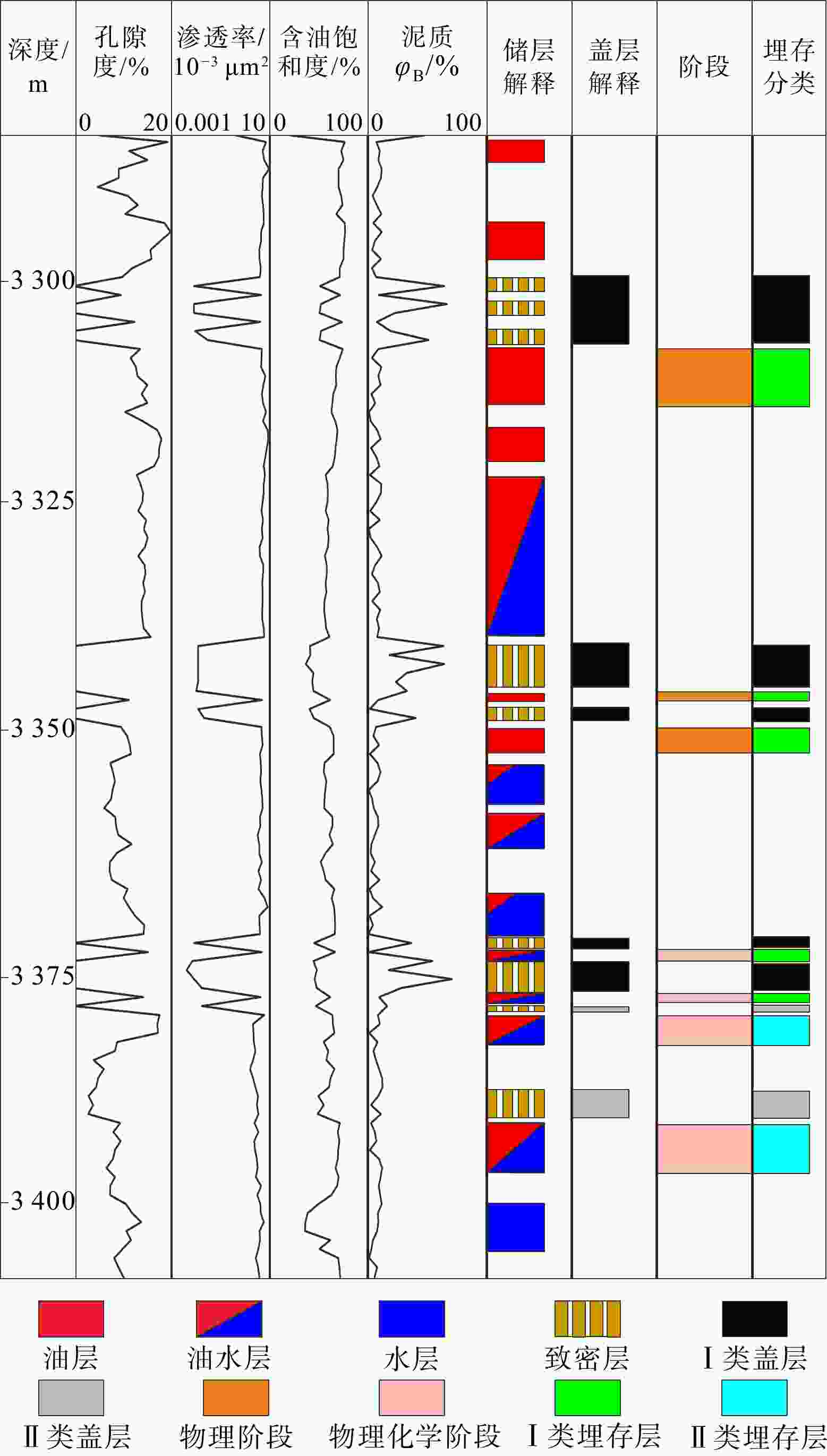

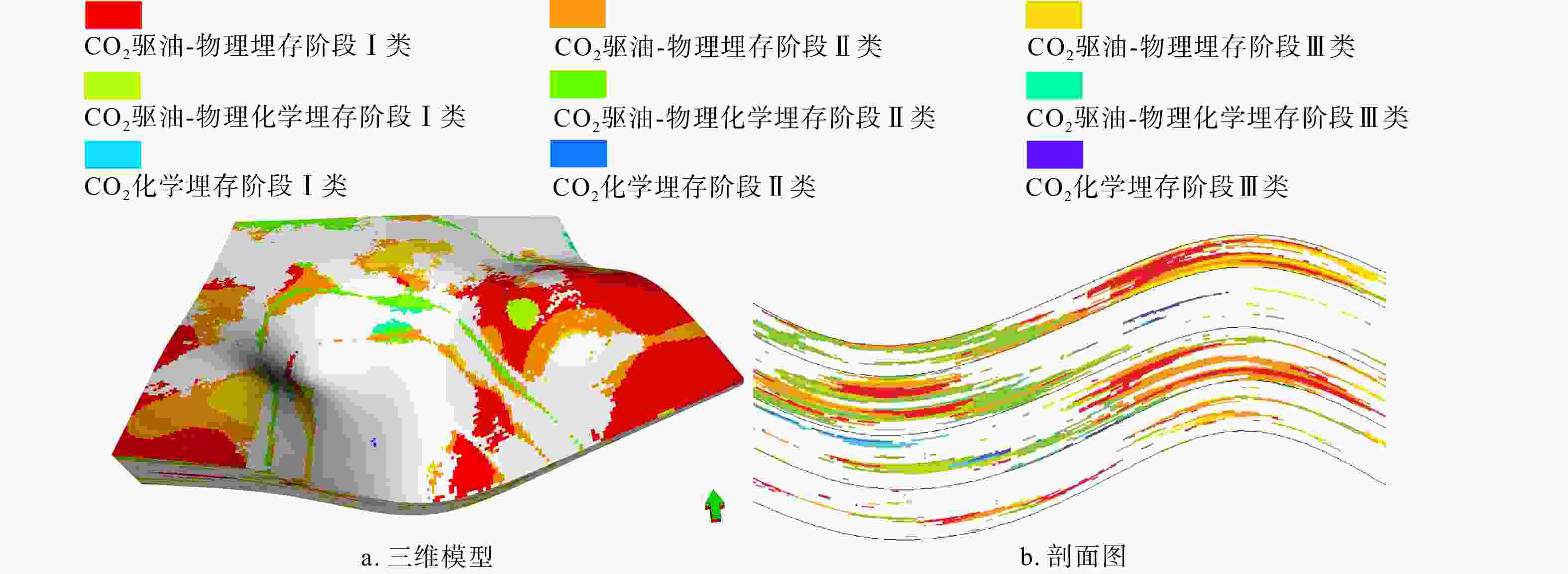

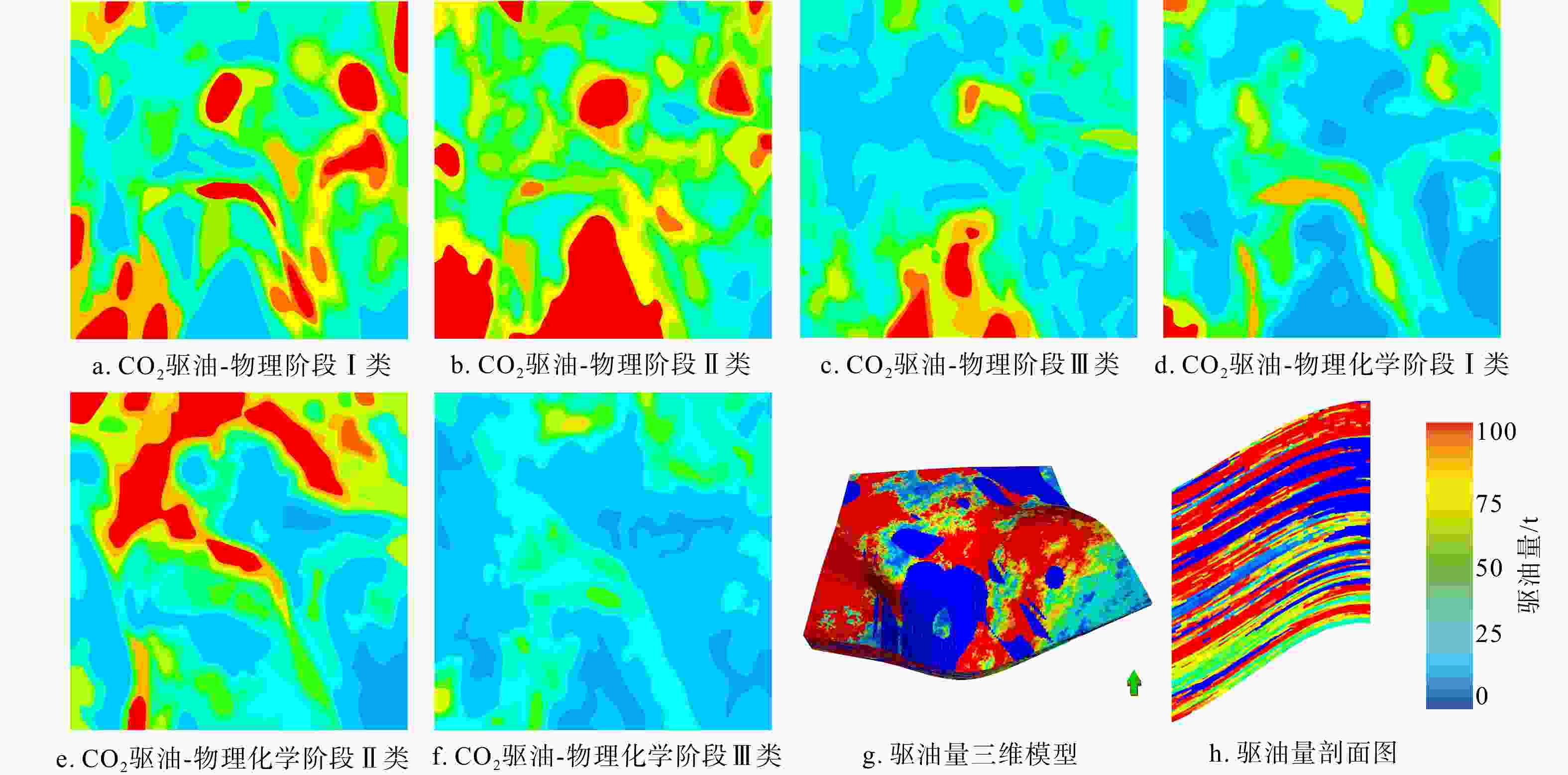

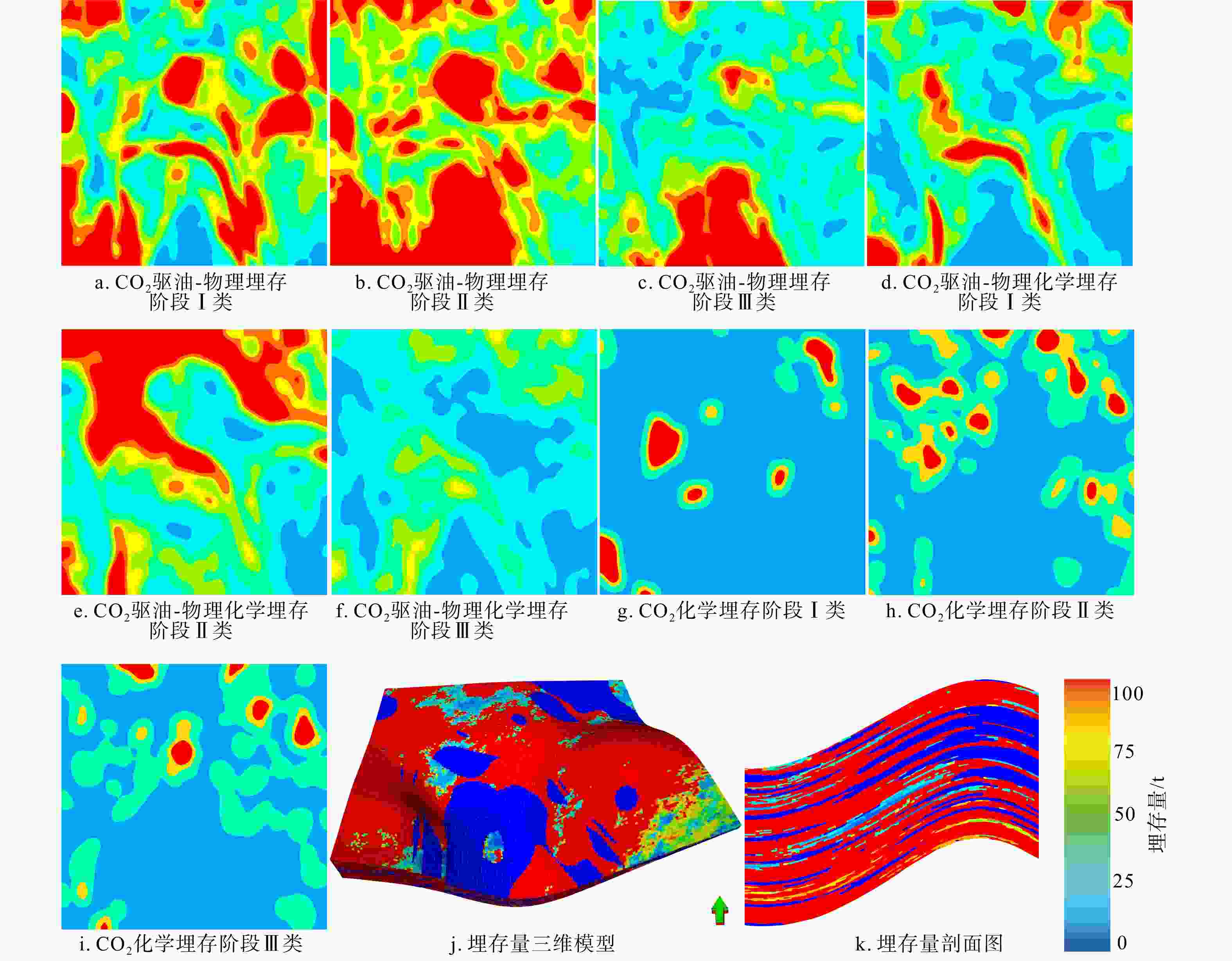

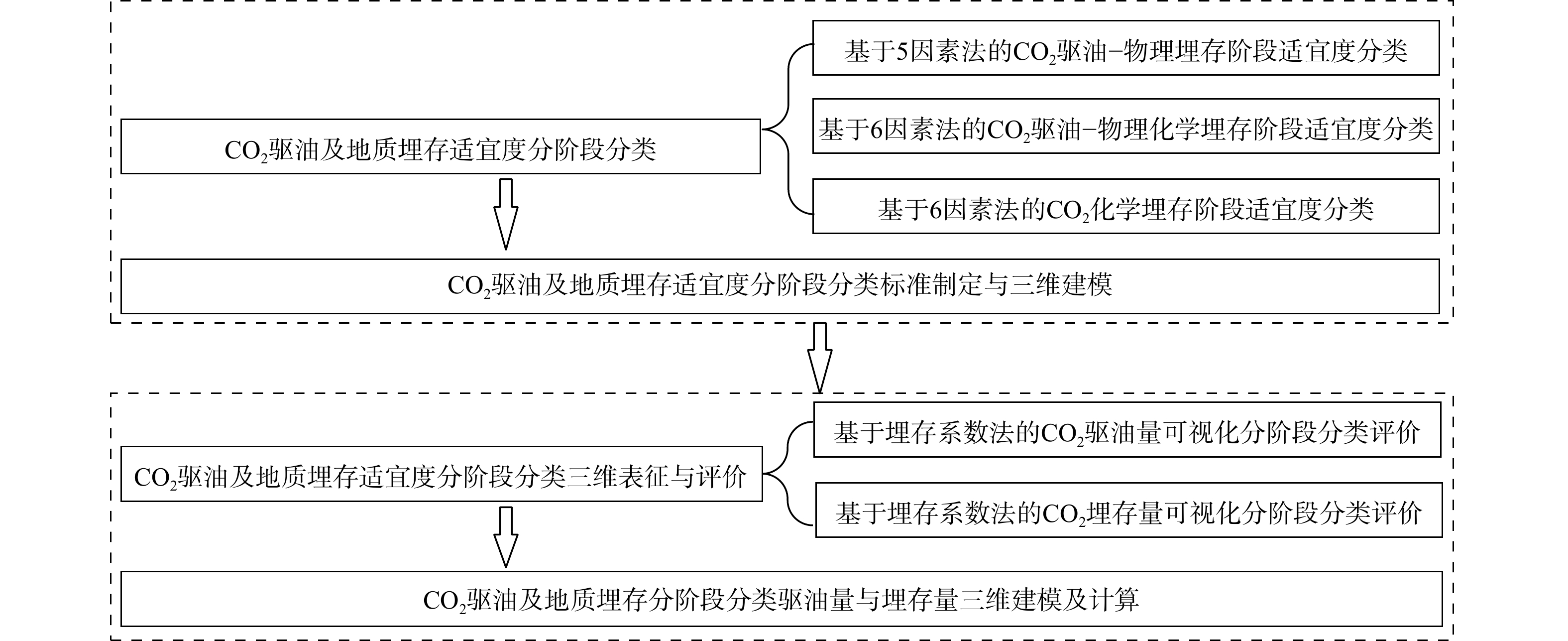

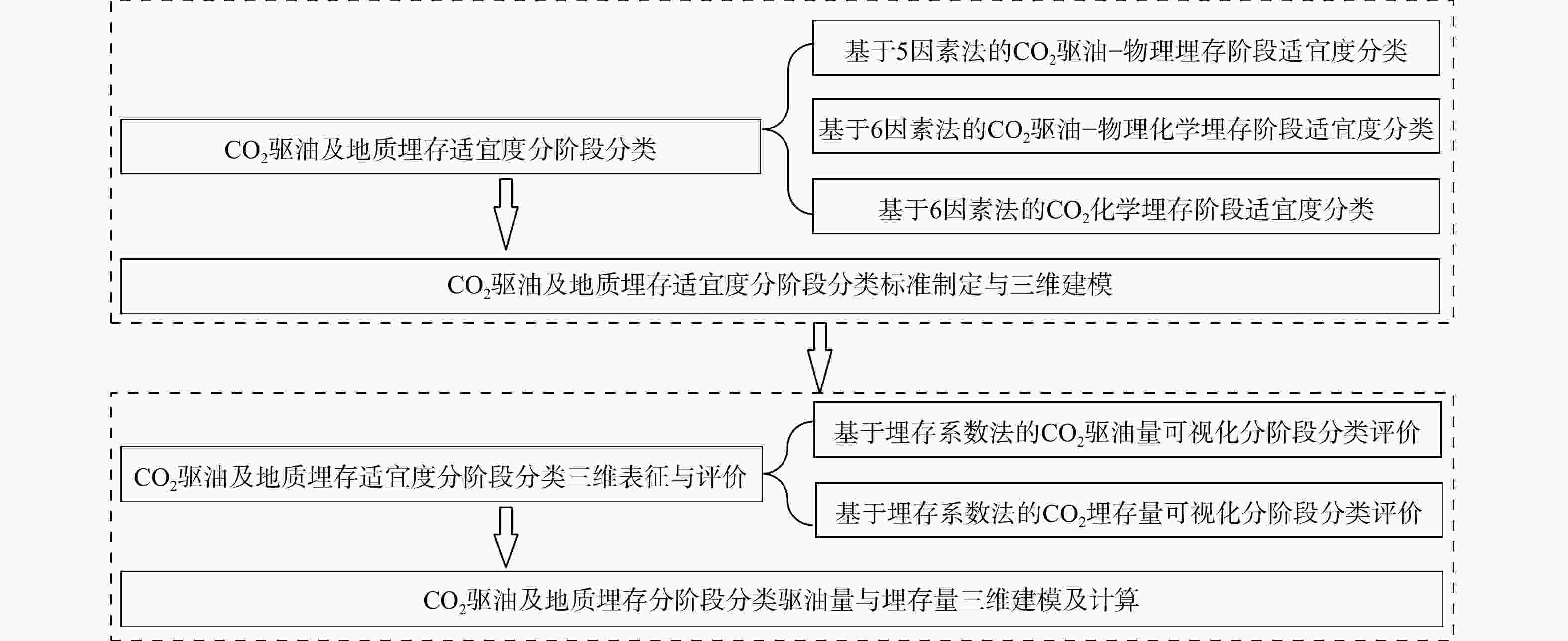

为实现CO2驱油及地质埋存适宜度、驱油量及埋存量表征与评价,在开发中后期油藏中充分考虑CO2驱油及地质埋存机制的阶段性差异,提出了CO2驱油及地质埋存适宜度的三阶段三类三维表征与评价方法。首先,开展CO2驱油及地质埋存适宜度分阶段分类研究,包括基于5因素法的CO2驱油-物理埋存阶段适宜度分类、基于6因素法的CO2驱油-物理化学埋存阶段适宜度分类、基于6因素法的CO2化学埋存阶段适宜度分类。然后,实施CO2驱油及地质埋存适宜度三阶段三类三维表征与评价,包括基于埋存系数法的CO2驱油量可视化分级分类评价、基于埋存系数法的CO2埋存量可视化分级分类评价。将提出的三阶段三类三维表征与评价方法应用于中国东部某典型低孔、特低渗油藏,先后建立了适宜度三阶段三类标准、适宜度三阶段三类三维模型、每个阶段各类储集体的驱油量与埋存量三维模型,计算出实例区三阶段各类储集体CO2驱油量648.24 t、埋存量

2956.84 t,表征了各阶段各类储集体CO2驱油及地质埋存的空间分布特征,为下一步CO2捕获、利用和存储(CO2 capture,utilization and storage,简称CCUS)项目精细化作业提供了技术支撑。-

关键词:

- CO2驱油及地质埋存 /

- 分阶段分类评价 /

- 三维表征 /

- 驱油量 /

- 埋存量

Abstract:Objective This study aims to propose a novel three-stage, three-category, three-dimensional characterization and evaluation method for CO2-enhanced oil recovery (EOR) and geological carbon storage (GCS).

Methods This method assesses the suitability, oil recovery, and storage capacity of these projects while addressing the distinct phase differences in the mechanisms of CO2 EOR and GCS during the later stages of reservoir development. This method involves the classification of CO2 EOR and GCS suitability into three stages: 1) physical storage suitability classification based on the five-factor method; 2) physicochemical storage suitability classification based on the six-factor method; and 3) chemical storage suitability classification based on the six-factor method. Additionally, this method provides a three-dimensional characterization and evaluation of CO2 EOR and GCS. It includes a visualization-based classification and assessment of the CO2 oil recovery amount and storage capacity using the storage coefficient method. The proposed evaluation framework has been applied to a representative low-porosity and ultralow-permeability reservoir in eastern China.

Results The calculated CO2 oil recovery and storage capacity for the sample area are 648.24 tons and

2956.84 tons, respectively. These results highlight the spatial distribution characteristics of CO2 EOR and GCS at each stage and type. Ultimately, this three-stage, three-category, three-dimensional characterization and evaluation method offers vital technical support for refining CCUS projects and provides meaningful insights for subsequent operations.Conclusion The findings contribute to the scientific and rational planning and implementation of CO2 EOR and GCS projects, facilitating the sustainable development of oil and gas fields and enhancing resource utilization efficiency.

-

图 4 实例区CO2驱油及地质埋存适宜度各阶段各类储集体驱油量三维建模结果(图例同图3)

Figure 4. Oil recovery quantities 3D model results of buried stock during different stages of CO2 EOR and GCS in the example area

图 5 实例区CO2驱油及地质埋存适宜度各阶段各类埋存量三维建模结果(图例同图3)

Figure 5. Storage capacity 3D model results of buried stock in different stages of CO2 EOR and GCS in the example area

表 1 CO2驱油及地质埋存适宜度评价指标体系

Table 1. Evaluation index system for CO2 EOR and GCS suitability

评价指标 权重 好 较好 中等 较差 差 油藏特征

(权重0.423)油藏温度/℃ 0.445 [60, 70) [70, 80) [80, 90) [90, 100] >100 [50, 60) [40, 50) [30, 40) <30 油藏压力/MPa 0.326 [8, 10) [10, 12) [12, 14) [14, 16] >16 [6, 8) [4, 6) [2, 4) <2 油藏深度/m 0.229 [900, 1500 )[ 1500 ,2000 )[ 2000 ,2500 )[ 2500 ,3000 ]> 3000 [800, 900) [700, 800) [600, 700) <600 储层特征

(权重0.354)渗透率/10−3 um2 0.371 ≥8 [1, 8) [0.1, 1) [0.01, 0.1) <0.01 孔隙度/% 0.371 ≥16 [12, 16) [8, 12) [2, 8) <2 储层厚度/m 0.258 [100, 10) [1, 7) [7, 4) [4, 1] <1或>100 流体特征

(权重0.223)原油饱和度/% 0.189 >60 [60, 40] <40 原油密度/(g·m−3) 0.351 <0.80 [0.80, 0.83) [0.83, 0.86) [0.86, 0.89] >0.89 原油黏度/(mPa·s) 0.351 <5 [5, 100) [100, 200) [200, 300] >300 地层水矿化度/(mg·L−1) 0.109 >150 [100, 150] [50, 100) [30, 50) <30 表 2 实例区单井解释油层、油水同层、水层统计

Table 2. Statistics of oil, oil-water and water layers of single well in the example area

储集体类型 油层 油水同层 水层 累计 平均厚度/m 57.26 36.82 12.90 35.66 占比/% 0.53 0.34 0.13 1.00 表 3 实例区CO2驱油及地质埋存适宜度三阶段分类标准

Table 3. Three-stage standard of CO2 EOR and GCS in the example area

阶段 物理埋存阶段 物理化学埋存阶段 化学埋存阶段 适宜度分类 Ⅰ类(好) Ⅱ类(中) Ⅲ类(差) Ⅰ类(好) Ⅱ类(中) Ⅲ类(差) Ⅰ类(好) Ⅱ类(中) Ⅲ类(差) 孔隙度/% ≥16 [12, 16) [8, 12) ≥16 [12, 16) [8, 12) ≥16 [12, 16) [8, 12) 渗透率/10−3 μm2 ≥8 [1, 8) [0.1, 1) ≥8 [1, 8) [0.1, 1) ≥8 [1, 8) [0.1, 1) 含油饱和度/% ≥90 [70, 90) [60, 70) [50, 60] [40, 50) [30, 40) ≥90 [70, 90) [60, 70) 盖层厚度/m Ⅰ类盖层≥1,Ⅱ类盖层≥2 埋存层厚度/m ≥2 ≥1 ≥0.5 ≥2 ≥1 ≥0.5 ≥2 ≥1 ≥0.5 原油密度/(t·m−3) ≤0.76 (0.76, 0.77) ≥0.77 ≤0.76 (0.76, 0.77) ≥0.77 地层水矿化度/(mg·L−1) [ 1000 ,1500 ][500, 1000 )[300, 500) [ 5000 ,10000 ][ 2000 ,5000 )[ 1500 ,2000 )温度/℃ 100~140 压力/MPa 28~44 油藏深度/m ≥ 3000 水型 CaCl2 表 4 各阶段各类储集体CO2驱油量可视化计算结果

Table 4. Calculation results of visual classification of CO2 displacement of different stages and different classifications

阶段 CO2驱油-物理埋存阶段 CO2驱油-物理化学埋存阶段 合计 适宜度分类 Ⅰ类 Ⅱ类 Ⅲ类 Ⅰ类 Ⅱ类 Ⅲ类 原油储量/t 1363.35 1435.10 486.34 550.12 802.60 191.35 4828.86 驱油量/t 272.67 215.27 48.63 44.01 56.18 11.48 648.24 表 5 CO2 的埋存量可视化分类计算结果

Table 5. Calculation results of visual classification of CO2 storage

阶段 CO2驱油-物理埋存阶段 CO2驱油-物理化学埋存阶段 CO2化学埋存阶段 合计 适宜度分类 Ⅰ类 Ⅱ类 Ⅲ类 Ⅰ类 Ⅱ类 Ⅲ类 Ⅰ类 Ⅱ类 Ⅲ类 物理埋存量/t 674.86 532.78 120.37 108.92 139.05 28.42 1604.39 化学埋存量/t 162.29 259.67 54.10 332.32 323.04 221.03 1352.45 合计/t 1328.01 752.45 876.39 2956.84 -

[1] 徐红. 实现智能化油气开采降低石油对外依存度[J]. 中国高新科技,2023,29(7):10-11.XU H. Realizing intelligent oil and gas exploitation to reduce oil dependence[J]. China High and New Technology,2023,29(7):10-11. (in Chinese with English abstract [2] 夏翠梅,王楠,刘景昱,等. “碳中和” 目标下海洋黑碳的源汇过程及其意义[J]. 地质科技通报,2024,43(2):318-329.XIA C M,WANG N,LIU J Y,et al. Source-sink processes of marine black carbon in the context of “carbon neutrality”[J]. Bulletin of Geological Science and Technology,2024,43(2):318-329. (in Chinese with English abstract [3] WANG Q,PFEIFFER H,AMAL R,et al. Introduction to CO2 capture,utilization and storage (CCUS)[J]. Reaction Chemistry & Engineering,2022,7(3):487-489. [4] DEZERN A E. Relevant metrics:How significant CCUS truly is?[J]. Blood,2021,138(11):918-919. [5] FØYEN T,ALCORN Z P,FERNØ M A,et al. CO2 mobility reduction using foam stabilized by CO2- and water-soluble surfactants[J]. Journal of Petroleum Science and Engineering,2021,196:107651. doi: 10.1016/j.petrol.2020.107651 [6] TAKHT RAVANCHI M,SAHEBDELFAR S. Catalytic conversions of CO2 to help mitigate climate change:Recent process developments[J]. Process Safety and Environmental Protection,2021,145:172-194. doi: 10.1016/j.psep.2020.08.003 [7] 牛皓,杜琼,许川东,等. 美国二氧化碳强化采油应用情况及对中国CCUS应用的启示[J]. 环境影响评价,2023,45(3):50-55.NIU H,DU Q,XU C D,et al. Application of carbon dioxide in enhanced oil recovery in USA and enlightenment of CCUS application to China[J]. Environmental Impact Assessment,2023,45(3):50-55. (in Chinese with English abstract [8] BAJPAI S,SHREYASH N,SINGH S,et al. Opportunities,challenges and the way ahead for carbon capture,utilization and sequestration (CCUS) by the hydrocarbon industry:Towards a sustainable future[J]. Energy Reports,2022,8:15595-15616. doi: 10.1016/j.egyr.2022.11.023 [9] ZHANG K,LAU H C,CHEN Z X. Extension of CO2 storage life in the Sleipner CCS project by reservoir pressure management[J]. Journal of Natural Gas Science and Engineering,2022,108:104814. [10] STORK A L,VERDON J P,KENDALL J M. The microseismic response at the in Salah carbon capture and storage (CCS) site[J]. International Journal of Greenhouse Gas Control,2015,32:159-171. doi: 10.1016/j.ijggc.2014.11.014 [11] 周银邦,王锐,赵淑霞,等. CO2封存过程中“适应性” 地质建模方法及案例[J]. 非常规油气,2022,9(6):1-8.ZHOU Y B,WANG R,ZHAO S X,et al. “Fit to purpose” geological modeling methods and cases in the process of CO2 storage[J]. Unconventional Oil & Gas,2022,9(6):1-8. (in Chinese with English abstract [12] HUMBUL S,RIZWAN N. CCUS:The Road to Net-Zero[J]. Energies,2023,16:4260. doi: 10.3390/en16114260 [13] HANS B,PIETER S. Offshore pipeline design for CCUS[J]. Pipeline & Gas Journal,2023,250(4):1-10. [14] FORS. Capturing the potential of CCUS[J]. World Oil,2022,243(3):47-49. [15] 郑长远,雷宏武,崔银祥,等. 西宁盆地南部天然CO2泄漏和浅部含水层响应[J]. 地质科技通报,2023,42(6):223-232.ZHEN C Y,LEI H W,CUI Y X,et al. Natural CO2 leakage and responses of shallow aquifers in the southern Xining Basin[J]. Bulletin of Geological Science and Technology,2023,42(6):223-232. (in Chinese with English abstract [16] EIDE L I,BATUM M,DIXON T,et al. Enabling large-scale carbon capture,utilisation,and storage (CCUS) using offshore carbon dioxide (CO2) infrastructure developments:A review[J]. Energies,2019,12(10):1945. doi: 10.3390/en12101945 [17] RECIOUI B,SETTOU N,KHALFI A,et al. Valorization of carbon dioxide by conversion into fuel using renewable energy in Algeria[J]. Transportation Research Part D(Transport and Environment),2016,43:145-157. [18] MALCOVATI L. IS09 - CCUS:Clinical perspective (high-risk CCUS)[J]. Leukemia Research,2023,128:107087. doi: 10.1016/j.leukres.2023.107087 [19] 杨国栋,李义连,马鑫,等. 超临界CO2增强热卤水开采模型研究[J]. 地质科技情报,2014,33(6):233-240.YANG G D,LI Y L,MA X,et al. Modeling study of enhanced thermal brine extraction using supercritical CO2[J]. Geological Science and Technology Information,2014,33(6):233-240. (in Chinese with English abstract [20] CAI M Y, LI X C, ZHANG K F, et al. Coupled hydro-mechanical-chemical simulation of CCUS-EOR with static and dynamic microscale effects in tight reservoirs[J]. Fuel, 2024, 357: 129888.CAI M Y,LI X C,ZHANG K F,et al. Coupled hydro-mechanical-chemical simulation of CCUS-EOR with static and dynamic microscale effects in tight reservoirs[J]. Fuel,2024,357:129888. [21] 张传宝,张东,李春光,等. CCUS驱油与封存的建模与优化研究[J]. 山东化工,2023,52(9):45-47.ZHANG C B,ZHANG D,LI C G,et al. Modeling and optimization of CCUS oil flooding and storage[J]. Shandong Chemical Industry,2023,52(9):45-47. (in Chinese with English abstract [22] 唐浩瑞. JS油田低效水平井注CO2吞吐适宜度及增油效果评价研究[D]. 成都:西南石油大学,2019.TANG H R. Evaluation of CO2 throughput suitability and oil increase effect of low-efficiency horizontal wells in JS oilfield [D]. Chengdu:Southwest Petroleum University,2019. (in Chinese with English abstract [23] 莫绍星,李瀛,龙星皎,等. 咸水层CO2矿物封存数值模拟研究进展[J]. 地质科技情报,2013,32(6):150-158.MO S X,LI Y,LONG X J,et al. Development of numerical simulation for CO2 mineral sequestration[J]. Geological Science and Technology Information,2013,32(6):150-158. (in Chinese with English abstract [24] 孟新. 中国CCUS-EOR项目经济效果及其提升手段研究[J]. 油气地质与采收率,2023,30(2):181-186.MENG X. Research on economic effect of China’s CCUS-EOR projects and its improvement methods[J]. Petroleum Geology and Recovery Efficiency,2023,30(2):181-186. (in Chinese with English abstract [25] 武守亚,杨建平,赵东亚,等. 基于侵入水影响的二氧化碳埋存量计算方法[J]. 石油工程建设,2016,42(4):18-22.WU S Y,YANG J P,ZHAO D Y,et al. Calculation method of carbon dioxide sequestration amount in consideration of aquifer influx[J]. Petroleum Engineering Construction,2016,42(4):18-22. (in Chinese with English abstract [26] 沈平平,廖新维,刘庆杰. 二氧化碳在油藏中埋存量计算方法[J]. 石油勘探与开发,2009,36(2):216-220. doi: 10.3321/j.issn:1000-0747.2009.02.012SHEN P P,LIAO X W,LIU Q J. Methodology for estimation of CO2 storage capacity in reservoirs[J]. Petroleum Exploration and Development,2009,36(2):216-220. (in Chinese with English abstract doi: 10.3321/j.issn:1000-0747.2009.02.012 [27] 中国石油天然气总公司. 中华人民共和国石油天然气行业标准油气储层评价方法[S]. 北京:中国石油天然气总公司,1997.China National Petroleum Corporation. People's Republic of China Oil and Gas Industry standard oil and gas reservoir evaluation method [S]. Beijing:PetroChina,1997. (in Chinese) -

下载:

下载: