Experimental study of recirculating heat transfer in geothermal wells with nanofluids

-

摘要:

提升换热介质的换热性能是高效开采地热资源的有效手段之一。添加纳米级金属氧化物可有效提升流体的换热能力, 而纳米颗粒种类、质量分数、粒径、分散剂质量分数等物性参数以及流速对纳米流体换热性能具有重要影响。采用球形纳米CuO和Al2O3(粒径20~50 nm)作为换热介质, 十二烷基苯磺酸钠(SDBS)作为分散剂配制纳米流体, 利用自主搭建的纳米流体基础换热实验装置进行室内换热实验, 优选纳米流体参数。此外, 通过自主搭建循环流动换热实验装置, 以湖北英山某水热型地热井中地热水作为热源, 讨论了在现场实际热源边界条件下, 流速对纳米流体和去离子水的换热性能影响规律。结果表明: (1)CuO纳米流体换热性能优于Al2O3纳米流体; (2)纳米流体的换热性能与纳米颗粒质量分数呈负相关关系, CuO质量分数为1%时纳米流体升温效率最高, 在150 s内温度可由25 ℃上升到79.2 ℃, 同时间内比去离子水高4.1 ℃, 同时, 随着纳米颗粒质量分数的增加, 纳米流体与热源界面的润湿性减小; (3)纳米流体换热性能随着纳米颗粒粒径增加呈现先增加后减小的趋势, 在纳米颗粒粒径为40 nm时纳米流体换热性能最佳; (4)纳米流体的换热性能与分散剂质量分数呈负相关关系, 当分散剂质量分数为1%时换热性能最佳; (5)层流状态下纳米流体的换热性能与流速呈负相关关系; 在湍流状态下纳米颗粒运动状态逐渐剧烈, 有利于纳米流体传热。研究成果可为纳米流体应用于地热换热从而提升地热系统的换热效率提供依据, 并为纳米流体参数以及流速参数的选择提供理论依据。

Abstract:Objective Enhancing the heat transfer performance of heat transfer media is an effective means of efficiently exploiting geothermal resources. Numerous studies have shown that the addition of nanoscale metals or metal oxides to fluids can effectively improve the heat transfer capacity of the fluid. The physical parameters that can impact the heat transfer performance of nanofluids are type, mass fraction, size of the nanoparticle, dispersant mass fraction. Additionally, the flow rate can have an important effect on the heat transfer performance of nanofluids.

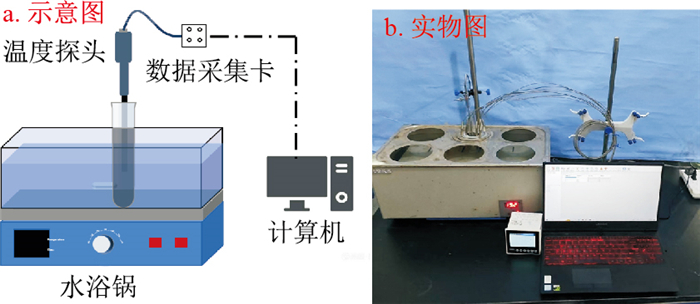

Methods In this study, spherical nano-CuO and spherical nano-Al2O3 were used as nanomaterials for configuring nanofluids. The particle size of nanomaterials ranges from 20 nm to 50 nm. Sodium dodecylbenzene sulfonate was selected as the dispersant for configuring the nanofluids. Basic heat transfer experiments are performed on nanofluids by utilizing a self-constructed basic heat transfer experimental setup. The physical parameters of the nanofluids were also optimized. In addition, a self-designed experimental setup for recirculating heat exchange was established. This experimental system uses geothermal water from hydrothermal geothermal wells as the heat source. The experimental system was also utilized for field testing in a hydrothermal-type geothermal well in Yingshan County, Hubei Province. The preferred nanofluid and deionized water from the basic heat transfer experiments were subjected to on-site circulating heat transfer experiments. Comparison of the circulating heat transfer performance of nanofluids and water under actual heat source conditions in the field. The effect of the flow rate on the heat transfer performance of nanofluids and water under real heat source boundary conditions in the field is also discussed.

Results The results show that (1) the heat transfer performance of CuO nanofluids is better than that of Al2O3 nanofluids. (2) There is a negative correlation between the heat transfer performance of nanofluids and the nanoparticle mass fraction. (3) The nanofluid warming efficiency was highest at a 1% mass fraction of CuO nanoparticles. The nanofluid temperature increased from 25 ℃ to 79.2 ℃ in 150 s. The nanofluid temperature increased by 4.1 ℃ more than that of deionized water in the same amount of time. Moreover, the wettability of the nanofluid-heat source interface decreases with increasing nanoparticle mass fraction. The heat transfer performance of nanofluids increases and then decreases with increasing particle size. The best heat transfer performance of the nanofluid was achieved when the nanoparticle size was 40 nm. (4) The heat transfer performance of nanofluids is negatively correlated with the dispersant mass fraction. The best heat transfer performance of the nanofluid was achieved when the dispersant mass fraction was 1%. (5) The heat transfer performance of the nanofluid is negatively correlated with the flow rate when the fluid is in laminar flow. The motion of nanoparticles is progressively more intense when the fluid is in a turbulent state. This phenomenon can effectively enhance the heat transfer performance of nanofluids.

Conclusion The research results can provide a basis for the application of nanofluids in geothermal heat transfer to improve the heat transfer efficiency of geothermal systems. It also provides theoretical references for the selection of nanofluid parameters as well as fluid flow rate parameters applied to geothermal heat transfer.

-

Key words:

- geothermal /

- nanofluid /

- recirculating heat transfer /

- nanoparticle /

- dispersant /

- heat transfer media /

- nano-CuO /

- nano-Al2O3

-

图 10 不同纳米颗粒(CuO)质量分数的纳米流体在不同温度下的接触角(θ)

a~e分别为w(CuO)=1%的纳米流体在30,40,50,60,70 ℃下的接触角;f~j分别为w(CuO)=2%的纳米流体在30,40,50,60,70 ℃下的接触角;k~o分别为w(CuO)=3%的纳米流体在30,40,50,60,70 ℃下的接触角;p~n分别为w(CuO)=4%的纳米流体在30,40,50,60,70 ℃下的接触角。w(SDBS)均为1%;CuO粒径均为40 nm

Figure 10. Contact angles of nanofluids with different nanoparticle mass fractions at different temperatures

-

[1] 王贵玲, 陆川. 碳中和目标驱动下地热资源开采利用技术进展[J]. 地质与资源, 2022, 31(3): 412-425. https://www.cnki.com.cn/Article/CJFDTOTAL-GJSD202203011.htmWANG G L, LU C. Progress of geothermal resources exploitation and utilization technology driven by carbon neutralization target[J]. Geology and Resources, 2022, 31(3): 412-425. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-GJSD202203011.htm [2] 解经宇, 王丹, 李宁, 等. 干热岩压裂建造人工热储发展现状及建议[J]. 地质科技通报, 2022, 41(3): 321-329. doi: 10.19509/j.cnki.dzkq.2022.0082XIE J Y, WANG D, LI N, et al. Development status and suggestions of hot dry rock hydraulic fracturing for building geothermal reservoirs[J]. Bulletin of Geological Science and Technology, 2022, 41(3): 321-329. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2022.0082 [3] 许天福, 姜振蛟, 袁益龙. 中深部地热资源开发利用研究现状与展望[J]. 中国基础科学, 2023, 25(3): 11-22. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJB202303002.htmXU T F, JIANG Z J, YUAN Y L. Research status and prospects of middle and deep geothermal resources exploitation and utilization[J]. China Basic Science, 2023, 25(3): 11-22. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJB202303002.htm [4] 刘德民, 张昌生, 孙明行, 等. 干热岩勘查评价指标与形成条件[J]. 地质科技通报, 2021, 40(3): 1-11. doi: 10.19509/j.cnki.dzkq.2021.0316LIU D M, ZHANG C S, SUN M H, et al. Evaluation indexes and formation conditions of hot dry rock exploration[J]. Bulletin of Geological Science and Technology, 2021, 40(3): 1-11. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2021.0316 [5] 汪集暘, 庞忠和, 程远志, 等. 全球地热能的开发利用现状与展望[J]. 科技导报, 2023, 41(12): 5-11. https://www.cnki.com.cn/Article/CJFDTOTAL-KJDB202312001.htmWANG J Y, PANG Z H, CHENG Y Z, et al. Current state, utilization and prospective of global geothermal energy[J]. Science & Technology Review, 2023, 41(12): 5-11. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-KJDB202312001.htm [6] 朱喜, 王贵玲, 马峰, 等. 雄安新区地热资源潜力评价[J]. 地球科学, 2023, 48(3): 1093-1106. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX202303018.htmZHU X, WANG G L, MA F, et al. Evaluation of geothermal resources of the Xiongan new area[J]. Earth Science, 2023, 48(3): 1093-1106. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX202303018.htm [7] 杜垚森, 封优生, 伍晓龙, 等. 深部地热能开发保温管技术研究现状及发展趋势[J]. 钻探工程, 2022, 49(6): 138-145. https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202206019.htmDU Y S, FENG Y S, WU X L, et al. Research status and consideration of thermal insulation pipe technology for deep geothermal energy development[J]. Drilling Engineering, 2022, 49(6): 138-145. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-TKGC202206019.htm [8] 王贵玲, 杨轩, 马凌, 等. 地热能供热技术的应用现状及发展趋势[J]. 华电技术, 2021, 43(11): 15-24. https://www.cnki.com.cn/Article/CJFDTOTAL-SLDL202111003.htmWANG G L, YANG X, MA L, et al. Status quo and prospects of geothermal energy in heat supply[J]. Huadian Technology, 2021, 43(11): 15-24. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-SLDL202111003.htm [9] 马峰, 蔺文静, 郎旭娟, 等. 我国干热岩资源潜力区深部热结构[J]. 地质科技情报, 2015, 34(6): 176-181. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201506025.htmMA F, LIN W J, LANG X J, et al. Deep geothermal structures of potential hot dry rock resources area in China[J]. Geological Science and Technology Information, 2015, 34(6): 176-181. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201506025.htm [10] 宋先知, 许富强, 宋国锋. 废弃井地热能开发技术现状与发展建议[J]. 石油钻探技术, 2020, 48(6): 1-7. https://www.cnki.com.cn/Article/CJFDTOTAL-SYZT202006001.htmSONG X Z, XU F Q, SONG G F. Technical status and development suggestions in exploiting geothermal energy from abandoned wells[J]. Petroleum Drilling Techniques, 2020, 48(6): 1-7(in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-SYZT202006001.htm [11] SOLTANI M, MORADI KASHKOOLI F, ALIAN FINI M, et al. A review of nanotechnology fluid applications in geothermal energy systems[J]. Renewable and Sustainable Energy Reviews, 2022, 167: 112729. doi: 10.1016/j.rser.2022.112729 [12] CHAPPIDI S, KUMAR A, SINGH J. Geothermal energy extraction from abandoned oil and gas wells using mono and hybrid nanofluids[J]. Geothermics, 2023, 114: 102794. doi: 10.1016/j.geothermics.2023.102794 [13] 宣益民. 纳米流体能量传递理论与应用[J]. 中国科学(技术科学), 2014, 44(3): 269-279. https://www.cnki.com.cn/Article/CJFDTOTAL-JEXK201403006.htmXUAN Y M. An overview on nanofluids and applications[J]. Scientia Sinica (Technologica), 2014, 44(3): 269-279. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-JEXK201403006.htm [14] 李强, 宣益民. 纳米流体对流换热的实验研究[J]. 工程热物理学报, 2002, 23(6): 721-723. https://www.cnki.com.cn/Article/CJFDTOTAL-GCRB200206017.htmLI Q, XUAN Y M. Experimental investigation on convective heat transfer of nanofluids[J]. Journal of Engineering Thermophysics, 2002, 23(6): 721-723. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-GCRB200206017.htm [15] CHOI U S, EASTMAN J A. Enhancing thermal conductivity of fluids with nanoparticles[J]. Asme. Fed., 1995, 231(1): 99-105. [16] WONGCHAREE K, EIAMSA-ARD S. Enhancement of heat transfer using CuO/water nanofluid and twisted tape with alternate axis[J]. International Communications in Heat and Mass Transfer, 2011, 38(6): 742-748. doi: 10.1016/j.icheatmasstransfer.2011.03.011 [17] 贾东, 蔡淑红, 李献强, 等. 纳米流体导热介质研究进展[J]. 材料导报, 2021, 35(增刊2): 540-549. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2021S2103.htmJIA D, CAI S H, LI X Q, et al. Research progress of nanofluid heat-conducting media[J]. Materials Reports, 2021, 35(S2): 540-549. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2021S2103.htm [18] 朱大海, 于伟, 朱桂华, 等. 氧化铜形貌对纳米流体强化传热性能的影响[J]. 科学通报, 2020, 65(增刊1): 222-228. https://www.cnki.com.cn/Article/CJFDTOTAL-KXTB2020Z1015.htmZHU D H, YU W, ZHU G H, et al. Influence of copper oxide with different morphologies on heat transfer performance of nanofluids[J]. Chinese Science Bulletin, 2020, 65(S1): 222-228. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-KXTB2020Z1015.htm [19] 翟昊, 李娟, 朱章钰. 纳米流体在微通道换热中的研究进展[J]. 热能动力工程, 2019, 34(12): 1-8. https://www.cnki.com.cn/Article/CJFDTOTAL-RNWS201912001.htmZHAI H, LI J, ZHU Z Y. Research progress of nanofluids heat transfer in microchannel[J]. Journal of Engineering for Thermal Energy and Power, 2019, 34(12): 1-8. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-RNWS201912001.htm [20] KAPICIOĜLU A, ESEN H. Experimental investigation on using Al2O3/ethylene glycol-water nano-fluid in different types of horizontal ground heat exchangers[J]. Applied Thermal Engineering, 2020, 165: 114559. doi: 10.1016/j.applthermaleng.2019.114559 [21] MURSHED S M S, LEONG K C, YANG C. Enhanced thermal conductivity of TiO2-water based nanofluids[J]. International Journal of Thermal Sciences, 2005, 44(4): 367-373. doi: 10.1016/j.ijthermalsci.2004.12.005 [22] ABBASIAN ARANI A A, AMANI J. Experimental investigation of diameter effect on heat transfer performance and pressure drop of TiO2-water nanofluid[J]. Experimental Thermal and Fluid Science, 2013, 44: 520-533. doi: 10.1016/j.expthermflusci.2012.08.014 [23] DIGLIO G, ROSELLI C, SASSO M, et al. Borehole heat exchanger with nanofluids as heat carrier[J]. Geothermics, 2018, 72: 112-123. doi: 10.1016/j.geothermics.2017.11.005 [24] TIWARI A K, GHOSH P, SARKAR J. Performance comparison of the plate heat exchanger using different nanofluids[J]. Experimental Thermal and Fluid Science, 2013, 49: 141-151. doi: 10.1016/j.expthermflusci.2013.04.012 [25] MAGHRABIE H M, ATTALLA M, A-A MOHSEN A. Performance assessment of a shell and helically coiled tube heat exchanger with variable orientations utilizing different nanofluids[J]. Applied Thermal Engineering, 2021, 182: 116013. doi: 10.1016/j.applthermaleng.2020.116013 [26] MAHIAN O, KIANIFAR A, SAHIN A Z, et al. Performance analysis of a minichannel-based solar collector using different nanofluids[J]. Energy Conversion and Management, 2014, 88: 129-138. doi: 10.1016/j.enconman.2014.08.021 [27] SAJID M U, ALI H M. Recent advances in application of nanofluids in heat transfer devices: A critical review[J]. Renewable and Sustainable Energy Reviews, 2019, 103: 556-592. doi: 10.1016/j.rser.2018.12.057 [28] DHARMAKKAN N, SRINIVASAN P M, MUTHUSAMY S, et al. A case study on analyzing the performance of microplate heat exchanger using nanofluids at different flow rates and temperatures[J]. Case Studies in Thermal Engineering, 2023, 44: 102805. doi: 10.1016/j.csite.2023.102805 [29] SUBRAMANI J, NAGARAJAN P K, MAHIAN O, et al. Efficiency and heat transfer improvements in a parabolic trough solar collector using TiO2 nanofluids under turbulent flow regime[J]. Renewable Energy, 2018, 119: 19-31. doi: 10.1016/j.renene.2017.11.079 [30] SUN X H, YAN H B, MASSOUDI M, et al. Numerical simulation of nanofluid suspensions in a geothermal heat exchanger[J]. Energies, 2018, 11(4): 919. doi: 10.3390/en11040919 [31] 李金玺, 孙东, 李智武, 等. 四川盆地水热型地热资源构造成因模式[J]. 地质科学, 2023, 58(2): 438-460. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKX202302006.htmLI J X, SUN D, LI Z W, et al. Structural genetic model of geothermal resources in Sichuan Basin[J]. Chinese Journal of Geology (Scientia Geologica Sinica), 2023, 58(2): 438-460. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-DZKX202302006.htm [32] 原若溪, 马峰, 张薇, 等. 地热储层改造技术研究进展[J]. 科技导报, 2022, 40(20): 52-64. https://www.cnki.com.cn/Article/CJFDTOTAL-KJDB202220007.htmYUAN R X, MA F, ZHANG W, et al. Application of geothermal reservoir modification technologies and prospective[J]. Science & Technology Review, 2022, 40(20): 52-64. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-KJDB202220007.htm [33] MONZO P, MOGENSEN P, ACUNA J, et al. A novel numerical approach for imposing a temperature boundary condition at the borehole wall in borehole fields[J]. Geothermics, 2015, 56: 35-44. [34] 毛绪美, 叶建桥, 董亚群, 等. 地热驱动力: 广东阳江新洲地热田驱动地热水运移的一种额外非重力作用的分析方法[J]. 地质科技通报, 2022, 41(1): 137-145. doi: 10.19509/j.cnki.dzkq.2022.0014MAO X M, YE J Q, DONG Y Q, et al. Geothermal driving force: A new additional non-gravity action driving the migration of geothermal water in the Xinzhou geothermal field of Yangjiang, Guangdong[J]. Bulletin of Geological Science and Technology, 2022, 41(1): 137-145. (in Chinese with English abstract) doi: 10.19509/j.cnki.dzkq.2022.0014 [35] SHEREMET M A, POP I, MAHIAN O. Natural convection in an inclined cavity with time-periodic temperature boundary conditions using nanofluids: Application in solar collectors[J]. International Journal of Heat and Mass Transfer, 2018, 116: 751-761. [36] WANG R J, CHEN T C, QI J L, et al. Investigation on the heat transfer enhancement by nanofluid under electric field considering electrophorestic and thermophoretic effect[J]. Case Studies in Thermal Engineering, 2021, 28: 101498. [37] FULE P J, BHANVASE B A, SONAWANE S H. Experimental investigation of heat transfer enhancement in helical coil heat exchangers using water based CuO nanofluid[J]. Advanced Powder Technology, 2017, 28(9): 2288-2294. [38] KUMAR N, SONAWANE S S, SONAWANE S H. Experimental study of thermal conductivity, heat transfer and friction factor of Al2O3 based nanofluid[J]. International Communications in Heat and Mass Transfer, 2018, 90: 1-10. [39] JANG S P, CHOI S U S. Role of Brownian motion in the enhanced thermal conductivity of nanofluids[J]. Applied Physics Letters, 2004, 84(21): 4316-4318. [40] ADAMCZYK Z, WEROŃSKI P. Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids)[J]. International Journal of Heat and Mass Transfer, 2002, 45(4): 855-863. [41] ADAMCZYK Z, WEROŃSKI P. Application of the DLVO theory for particle deposition problems[J]. Advances in Colloid and Interface Science, 1999, 83(1/3): 137-226. [42] COURSEY J S, KIM J. Nanofluid boiling: The effect of surface wettability[J]. International Journal of Heat and Fluid Flow, 2008, 29(6): 1577-1585. [43] 李泽梁, 李俊明, 胡海滔, 等. CuO纳米颗粒悬浮液中各组分对悬浮液稳定性及黏度的影响[J]. 热科学与技术, 2005, 4(2): 157-163. https://www.cnki.com.cn/Article/CJFDTOTAL-RKXS200502012.htmLI Z L, LI J M, HU H T, et al. Influence of ingredients of copper oxide nano-suspension on stability and viscosity of suspension[J]. Journal of Thermal Science and Technology, 2005, 4(2): 157-163. (in Chinese with English abstract) https://www.cnki.com.cn/Article/CJFDTOTAL-RKXS200502012.htm -

下载:

下载: