Mechanical model and pipe diameter optimization of a pipe jacking roof in river crossings according to the Pasternak elastic foundation beam

-

摘要:

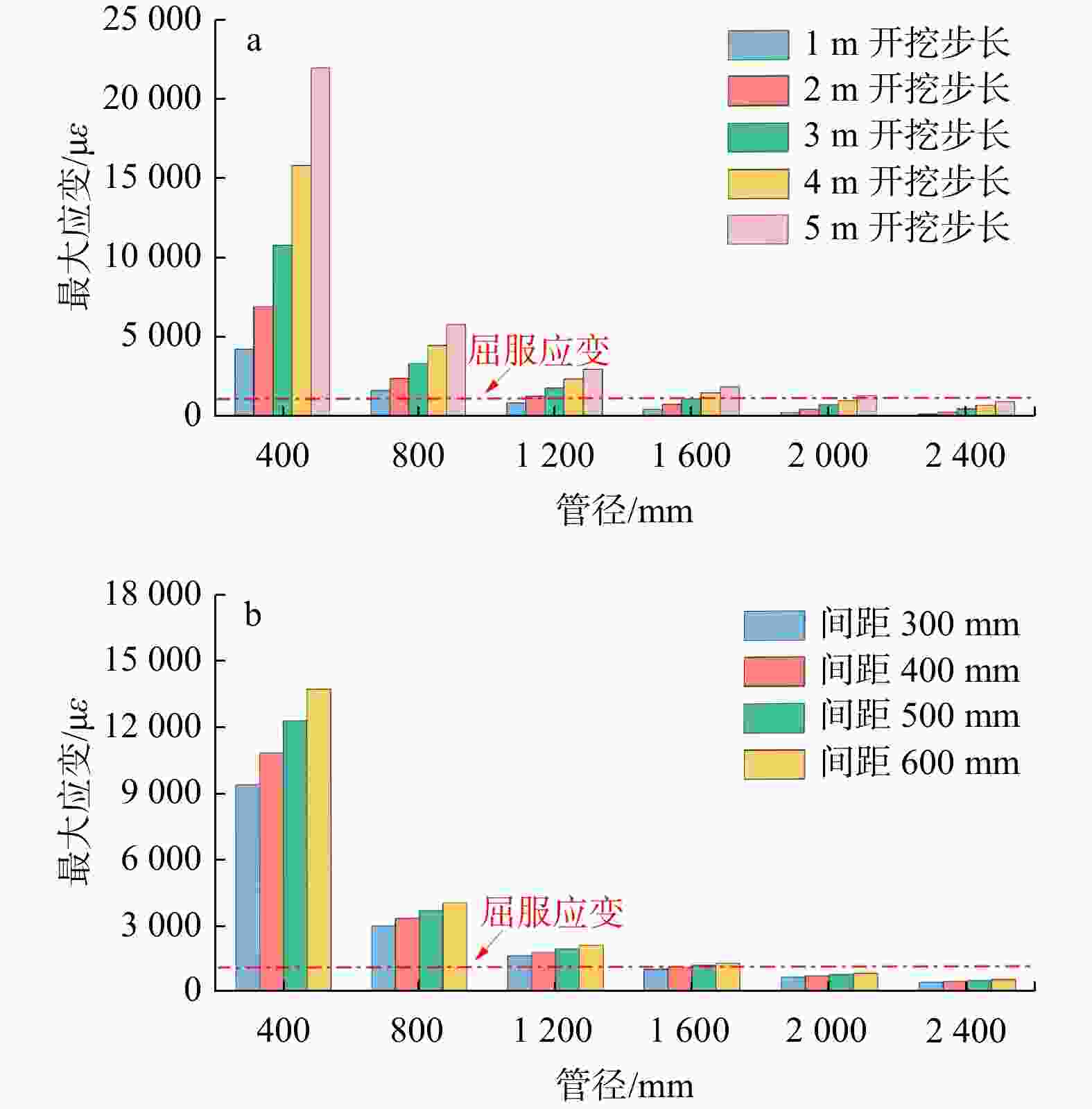

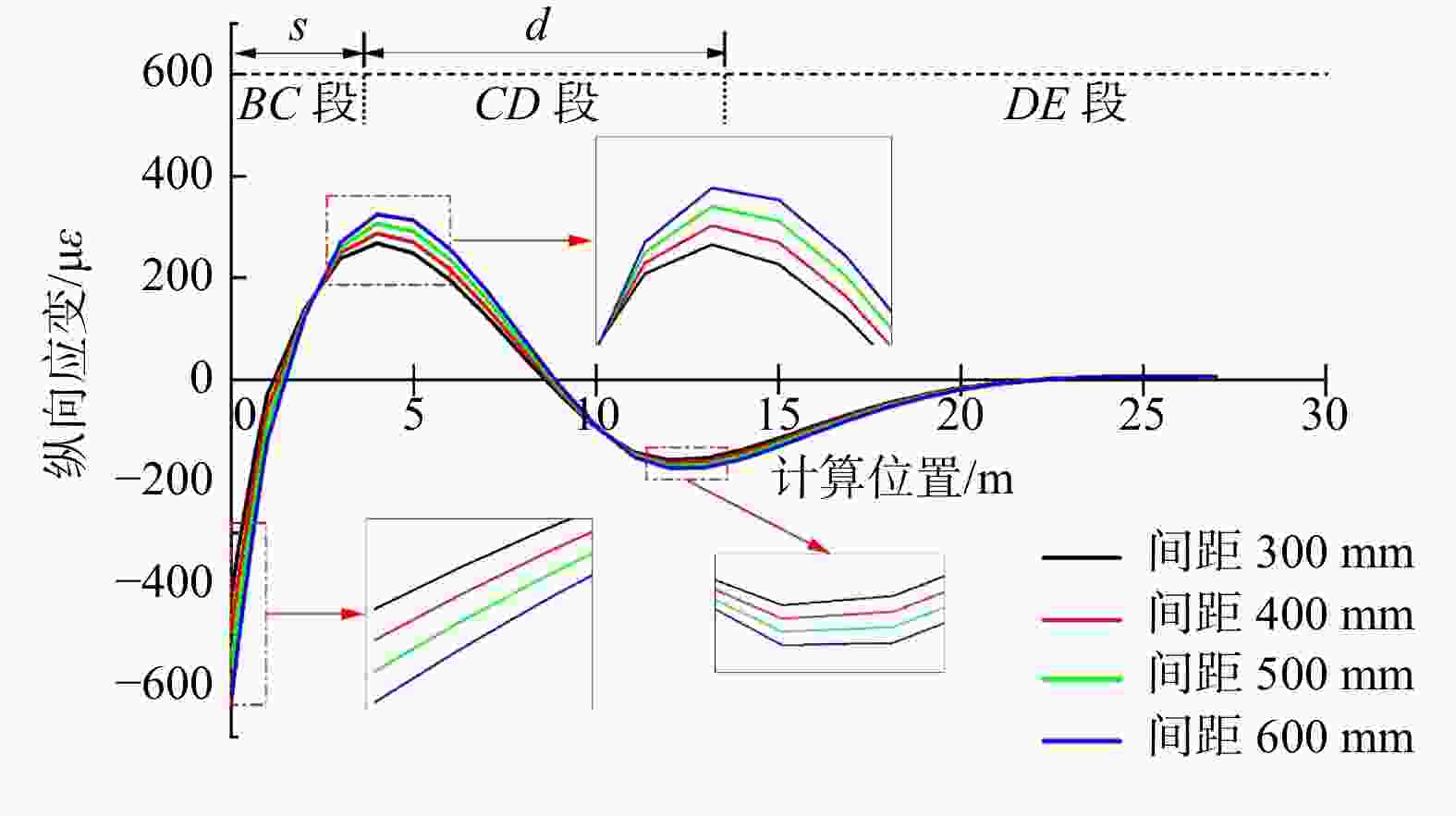

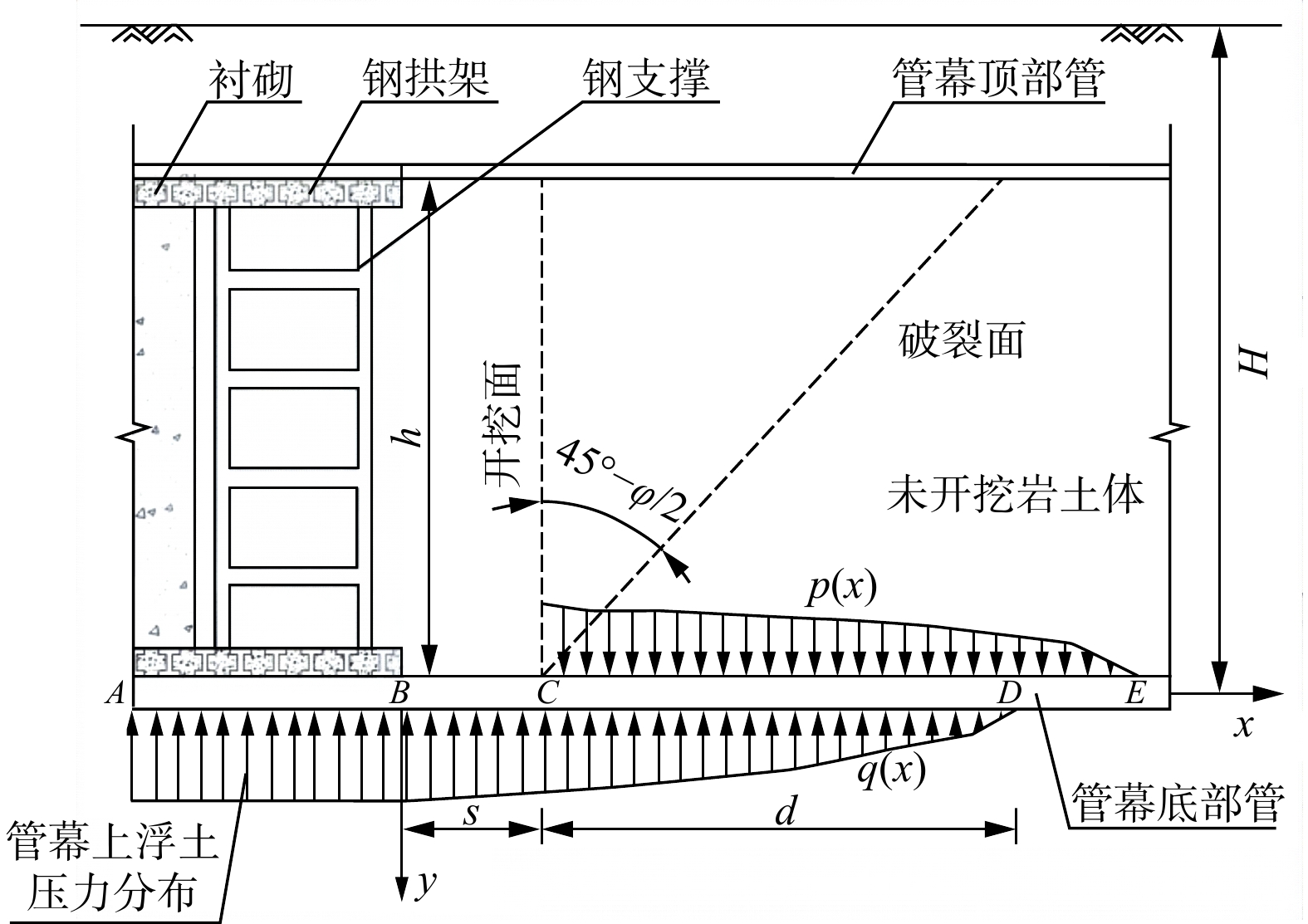

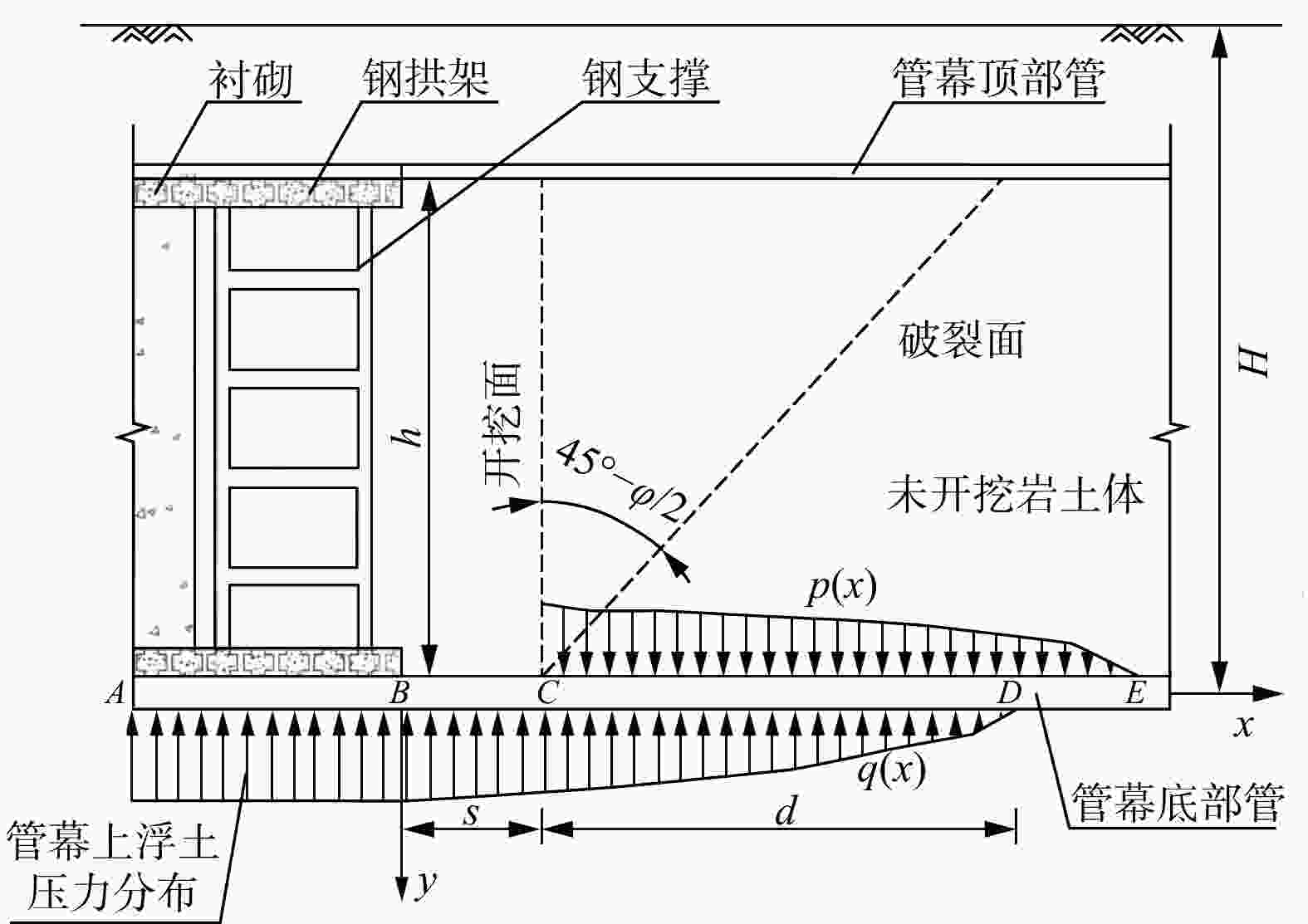

支护管的受力特性分析是顶管管幕结构设计的基础,其保证了隧道开挖的安全。为了分析隧道开挖过程中顶管管幕力学特性,基于Pasternak模型构建管幕底部支护管力学解析模型,充分利用位移、转角、弯矩和剪力连续性条件,推导出支护管位移及内力方程,且计算结果更接近于工程实测应变,证明模型具有适用性。同时以秦淮新河段顶管管幕为例,通过分析支护管最大应变变化规律优选出合理的管幕直径。研究表明:初期管径对管幕底部支护管支护性能影响较大,后期随管径增大影响逐渐减小至平稳;开挖步长和管间间距对支护管支护性能呈正相关影响,小管径时对支护管最大应变影响更明显;管间距对支护管纵向应变影响较小,管幕卸载杠杆作用可有效将开挖区卸载值传递至非开挖区,从而保证管幕开挖面稳定性。

-

关键词:

- 穿河隧道 /

- 顶管管幕 /

- Pasternak弹性地基梁 /

- 受力特性 /

- 管径优化

Abstract:The analysis of the force characteristics of the support pipe is the basis for the structural design of the pipe jacking roof, which ensures the safety of tunnel excavation.

Objective In order to analyze the mechanical behavior of the pipe roof during tunnel excavation,

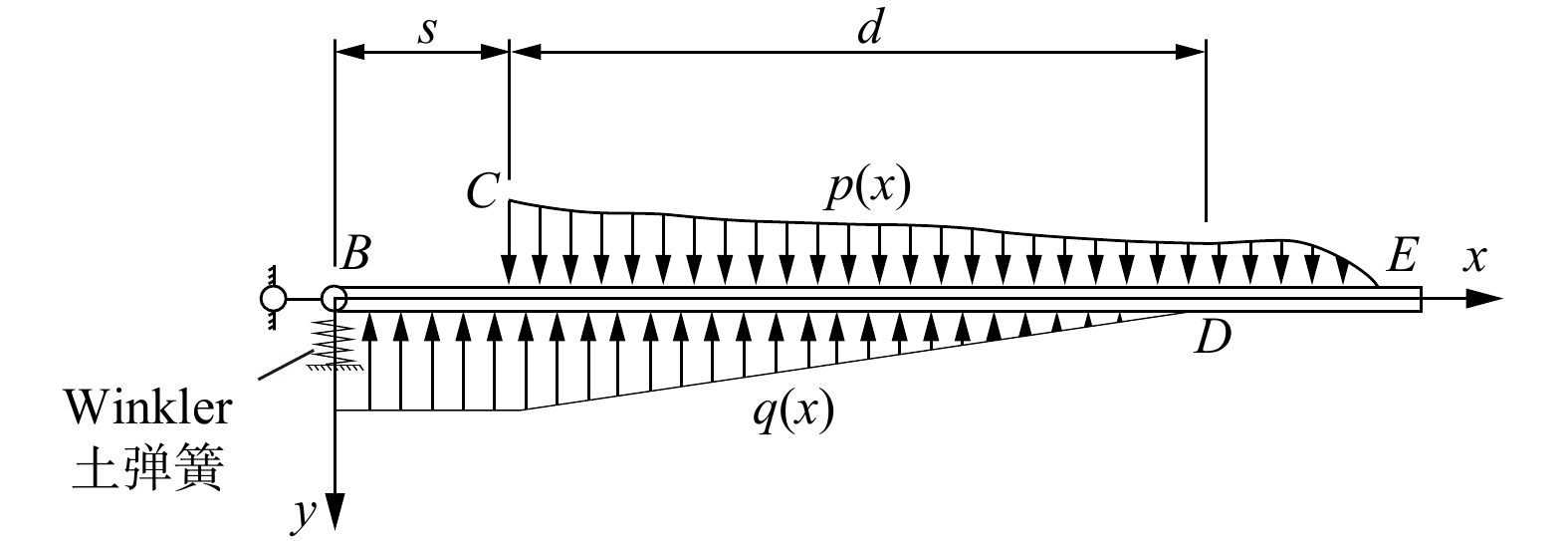

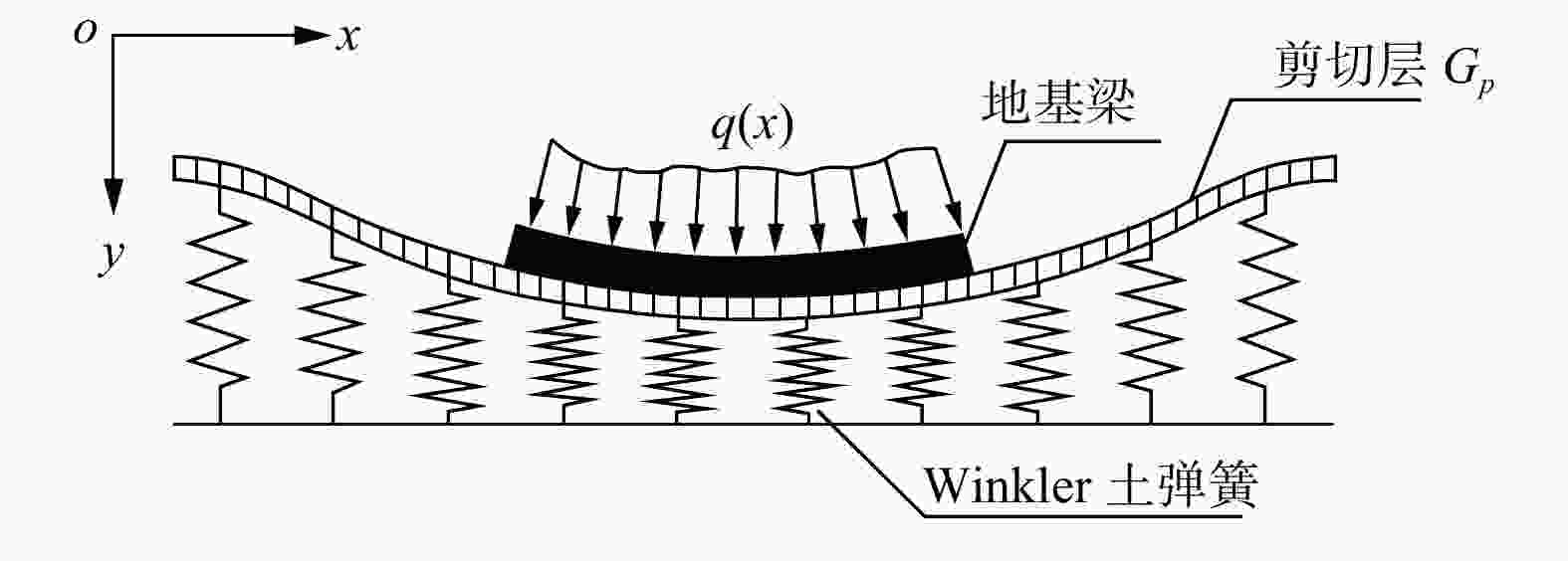

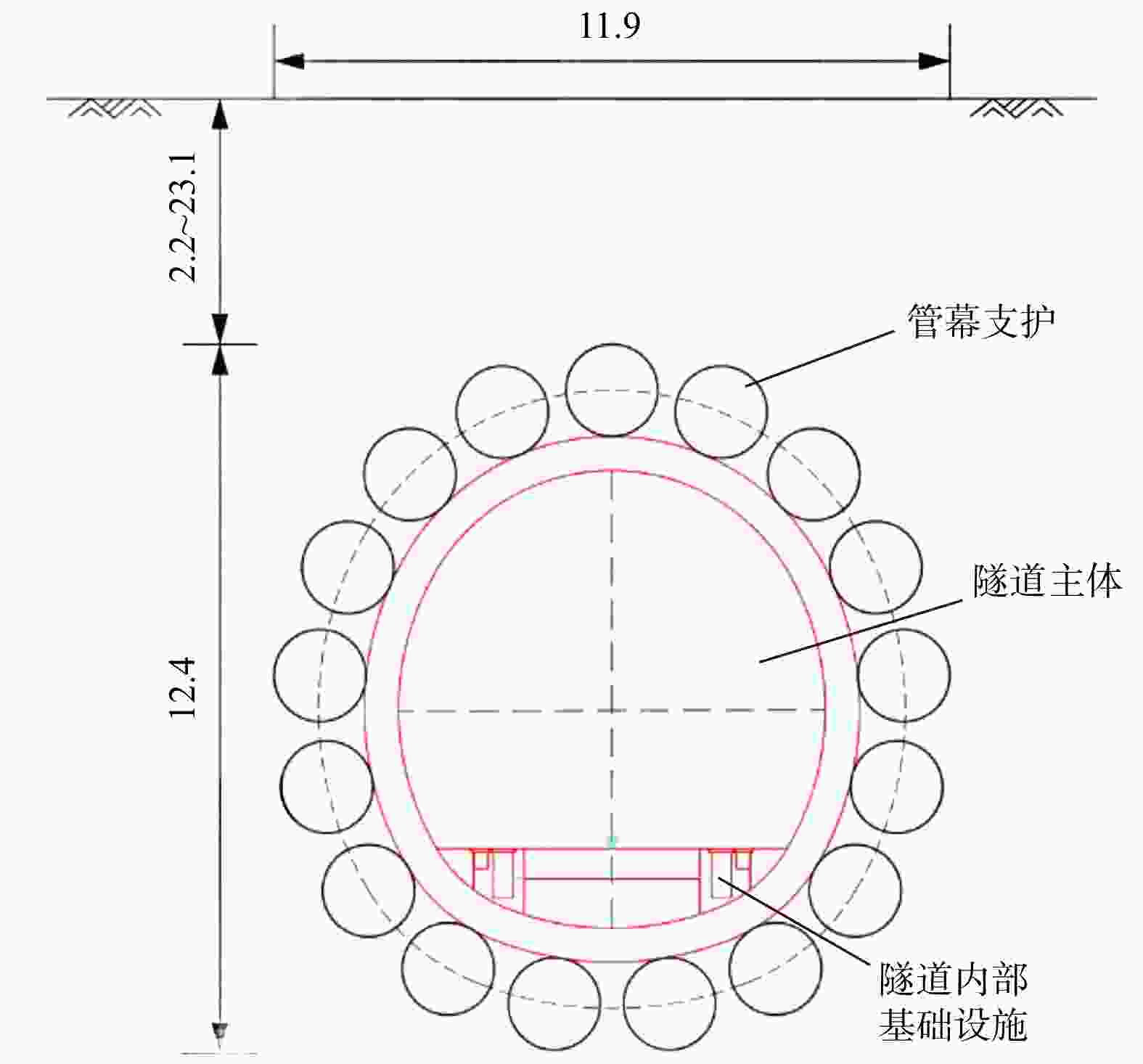

Methods an analytical model of the support pipe at the bottom of the pipe jacking roof is constructed based on the Pasternak elastic foundation beam theory, making full use of the displacement, rotation, bending moment, and shear continuity conditions to derive the displacement and internal force equations of the support pipe.

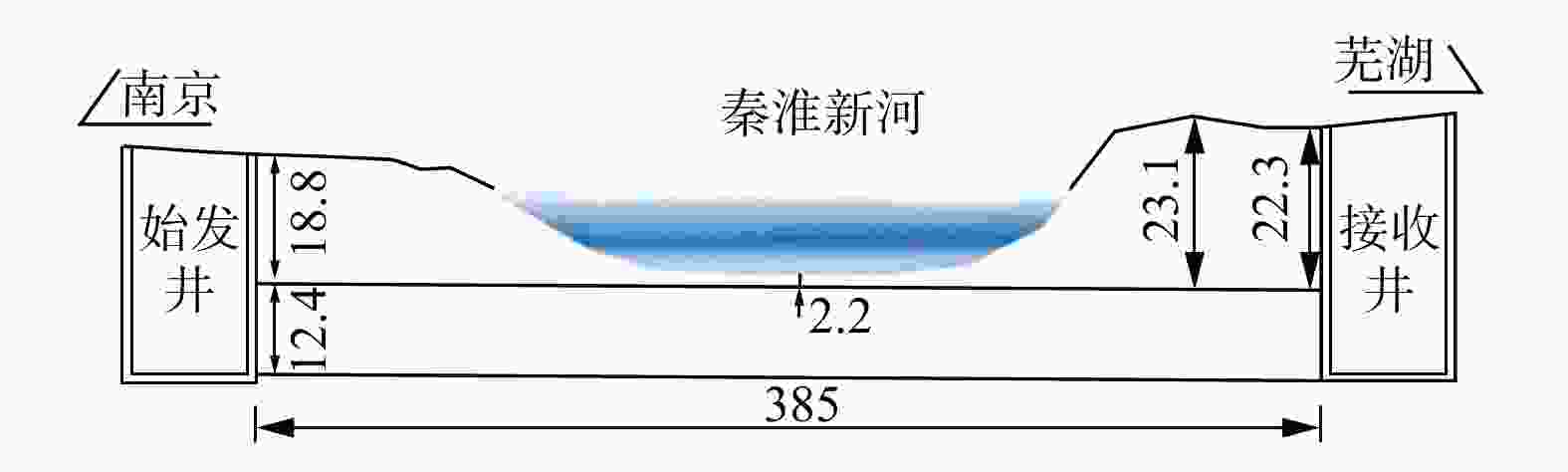

Results The calculation results are in close agreement with the measured strain from the project, proving the applicability of the model. Moreover, by analyzing the maximum strain change law of the support pipe, the reasonable pipe roof diameter was selected, using the pipe jacking roof of the Qinhuai New River section as an example.

Conclusion The research shows that the initial pipe diameter significantly influences the support performance of the bottom support pipe, with this influence gradually decreasing as the pipe diameter increases. The excavation step length and pipe spacing positively impact the support performance, with a more pronounced effect on the maximum strain of the support pipe when the pipe diameter is small. Pipe spacing has minimal effect on the longitudinal strain of the support pipe. The unloading lever of the pipe jacking roof can effectively transfer the unloading value from the excavation area to the unexcavated area, thus ensuring the stability of the excavation surface of the pipe jacking roof.

-

表 1 不同计算模型支护管应变对比表

Table 1. Comparison of the supporting pipe strains for different calculation models

计算模型 1.2 m测点应变/με 8.2 m测点应变/με 现场实测值 −174 15.84 −260 −31.68 实测平均值 −217 −7.92 文献[7]模型 −290 18.00 本研究模型 −236 −0.50 表 2 地层参数

Table 2. Formation parameters

地层 厚度/

m黏聚力/

kPa内摩擦角/

(°)压缩模量/

MPa密度/

(g·cm−3)1杂填土 1.4 — — — 1.75 2粉质黏土 5.6 39.96 11.18 6.01 1.95 1粉质黏土 0.5 30.15 9.72 4.75 1.93 2粉质黏土 7.8 44.56 12.50 7.26 1.98 5-2强风化长石

石英砂岩1.3 — — — 2.55 5-3弱风化长石

石英砂岩— 3.60 54.70 — 2.41 -

[1] 周雨恒,周浩,袁明,等. 考虑管土接触状态的圆曲线顶管顶进力计算方法[J]. 地质科技通报,2023,42(3):63-71.ZHOU Y H,ZHOU H,YUAN M,et al. Jacking force calculation method of circular curved pipe jacking with consideration of pipe-soil contact characteristics[J]. Bulletin of Geological Science and Technology,2023,42(3):63-71. (in Chinese with English abstract [2] 徐天硕,王乐,刘锴鑫,等. 基于滚刀破岩特性的岩石顶管迎面阻力计算模型[J]. 地质科技通报,2022,41(4):259-265.XU T S,WANG L,LIU K X,et al. A calculation model for the head-on resistance of rock pipe jacking based on the rock breaking characteristics of the disc cutter[J]. Bulletin of Geological Science and Technology,2022,41(4):259-265. (in Chinese with English abstract [3] 兰彬,张鹏,张云龙,等. 矩形顶管管周差异摩阻力对地层纵向水平位移的影响[J]. 地质科技通报,2022,41(3):215-221.LAN B,ZHANG P,ZHANG Y L,et al. Influence of differential frictional resistance around rectangular pipe jacking on longitudinal horizontal displacement of strata[J]. Bulletin of Geological Science and Technology,2022,41(3):215-221. (in Chinese with English abstract [4] 袁心,马保松,赵阳森,等. 矩形顶管施工中管周压力的实测与分析[J]. 地下空间与工程学报,2021,17(4):1225-1233.YUAN X,MA B S,ZHAO Y S,et al. Field measurement and analysis of pipe pressure during box jacking construction[J]. Chinese Journal of Underground Space and Engineering,2021,17(4):1225-1233. (in Chinese with English abstract [5] 牛国伦,马保松,张鹏,等. 大直径顶管施工管土相互作用实测分析——以佛山市电力隧道顶管工程为例[J]. 隧道建设(中英文),2021,41(8):1353-1360.NIU G L,MA B,ZHANG P,et al. Measurement analysis of pipe-soil interaction in large-diameter pipe jacking project of a power tunnel in Foshan,China[J]. Tunnel Construction,2021,41(8):1353-1360. (in Chinese with English abstract [6] ZHANG P,BEHBAHANI S S,MA B S,et al. A jacking force study of curved steel pipe roof in Gongbei tunnel:Calculation review and monitoring data analysis[J]. Tunnelling and Underground Space Technology,2018,72:305-322. doi: 10.1016/j.tust.2017.12.016 [7] ZHANG P,MA B S,ZENG C,et al. Key techniques for the largest curved pipe jacking roof to date:A case study of Gongbei tunnel[J]. Tunnelling and Underground Space Technology,2016,59:134-145. doi: 10.1016/j.tust.2016.07.001 [8] ZHANG P,FENG X,ZENG C,et al. Field performance of steel pipes during curve jacking in Gongbei tunnel[J]. Tunnelling and Underground Space Technology incorporating Trenchless Technology Research,2022,128:104585. [9] HAO Z,ZHANG H,ZHANG G,et al. The prediction of ground settlement of a box culvert jacked under the action of an ultra-shallow buried pipe curtain[J]. Arabian Journal for Science and Engineering,2022,47(10):12423-12438. doi: 10.1007/s13369-021-06417-6 [10] LIU X,ZHANG R,HHANG J,et al. Deformation mechanism and limit support pressure of cutting steel plate during connection between pipes in large spacing using pipe curtain structure method[J]. Underground Space,2024,18:83-96. doi: 10.1016/j.undsp.2023.12.003 [11] 吉小明,龙兵,杨雪强. 管幕预加固中近接顶管施工的三维模拟分析[J]. 地下空间与工程学报,2016,12(增刊):267-274.JI X M,LONG B,YANG X Q. Three-dimensional simulation analysis of adjacent pipe jacking construction in pipe curtain pre-reinforcement[J]. Chinese Journal of Underground Space and Engineering,2016,12(S1):267-274. (in Chinese) [12] 沈桂平,曹文宏,杨俊龙,等. 管幕法综述[J]. 岩土工程界,2006(2):27-29.SHEN G P,CAO W H,YANG J L,et al. Summary of tube curtain method[J]. Geotechnical Engineering,2006(2):27-29. (in Chinese) [13] 朱合华,闫治国,李向阳,等. 饱和软土地层中管幕法隧道施工风险分析[J]. 岩石力学与工程学报,2005,24(增刊2):5549-5554.ZHU H H,YAN Z G,LI X Y,et al. Risk analysis of pipe-curtain tunnel construction in saturated soft soil stratum[J]. Journal of Rock Mechanics and Engineering,2005,24(S2):5549-5554. (in Chinese) [14] 刘学增,朱合华,官林星,等. 管幕法隧道施工方案研究[C]//佚名中国土木工程学会第十一届、隧道及地下工程分会第十三届年会论文集. 北京:[出版社不详],2004:5.LIU X Z,ZHU H H,GUAN L X,et al. Research on tunnel construction scheme of tube curtain method[C]//Anon. Proceedings of the 11th Annual Conference of the Chinese Society of Civil Engineers and the 13th Annual Conference of the Branch of Tunneling and Underground Engineering. Beijing:[s. n. ],2004:5. (in Chinese) [15] 常艄东. 管棚法超前预支护作用机理的研究[D]. 成都:西南交通大学,1999:36-43.CHANG S D. Study on the mechanism of advanced pre-support by pipe shed method[D]. Chengdu:Southwest Jiaotong University,1999:36-43. (in Chinese with English abstract [16] 王家乐,夏桂云. Winkler地基上修正Timoshenko梁振动分析[J]. 振动与冲击,2020,39(3):30-37.WANG J L,XIA G Y. Vibration analysis for a modified Timoshenko beam on Winkler elastic foundation[J]. Journal of Vibration and Shock,2020,39(3):30-37. (in Chinese with English abstract [17] 丁敏,李静,罗双,等. 基于直接刚度法的弹性地基深梁单元[J]. 铁道学报,2020,42(5):136-142. doi: 10.3969/j.issn.1001-8360.2020.05.018DING M,LI J,LUO S,et al. Deep beam element on elastic foundation based on direct stiffness method[J]. Journal of The China Railway Society,2020,42(5):136-142. (in Chinese with English abstract doi: 10.3969/j.issn.1001-8360.2020.05.018 [18] 马建军,秦紫果,刘丰军,等. 考虑有限深度土体运动的Winkler地基梁自由振动分析[J]. 振动与冲击,2019,38(6):62-66+99.MA J J,QIN Z G,LIU F J,et al. Free vibration of beams on winkler foundation with the consideration of finite-depth soil motion[J]. Journal of Vibration and Shock,2019,38(6):62-66+99. (in Chinese with English abstract [19] 代云云,周晶. 改进的Winkler弹性地基模型在触地段动力分析中的应用[J]. 哈尔滨工程大学学报,2018,39(9):1451-1457.DAI Y Y,ZHOU J. Application of an improved Winkler elastic foundation-based model to the dynamic analysis of damaged pipelines in the touchdown zone[J]. Journal of Harbin Engineering University,2018,39(9):1451-1457. (in Chinese with English abstract [20] 苟德明,阳军生,张 戈. 浅埋暗挖隧道管棚变形监测及受力机制分析[J]. 岩石力学与工程学报,2007,26(6):1258-1264. doi: 10.3321/j.issn:1000-6915.2007.06.023GOU D M,YANG J S,ZHANG G. Deformation monitoring and mechanical behaviors of pipe-roof in shallow tunnels[J]. Chinese Journal of Rock Mechanics and Engineering,2007,26(6):1258-1264. (in Chinese with English abstract doi: 10.3321/j.issn:1000-6915.2007.06.023 [21] 张俊儒,严丛文,叶伦,等. 箱涵顶进对下方管幕的力学作用分析[J]. 隧道建设(中英文),2019,39(增刊1):73-79.ZHANG J R,YAN C W,YE L,et al. Mechanical analysis of box culvert jacking on the lower pipe curtain[J]. Tunnel Construction,2019,39(S1):73-79. (in Chinese) [22] 肖旻,王正中,吴浪,等. 基于双参数弹性地基梁理论的梯形渠道冻胀力学模型[J]. 农业工程学报,2022,38(14):71-78. doi: 10.11975/j.issn.1002-6819.2022.14.009XIAO M,WANG Z Z,WU L,et al. Frost-heaving mechanical model of concrete lining trapezoidal canal based on two-parameter elastic foundation beam theory[J]. Transactions of the Chinese Society of Agricultural Engineering,2022,38(14):71-78. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2022.14.009 [23] 张金轮,张阿祥,葛仁余,等. 三参数Pasternak黏弹性地基中锥形桩的横向自由振动特性研究[J]. 振动与冲击,2022,41(6):183-196.ZHANG J L,ZHANG A X,GE R Y,et al. Transverse free vibration characteristics of a tapered pile in the three-parameter Pasternak viscoelastic foundation[J]. Journal of Vibration and Shock,2022,41(6):183-196. (in Chinese with English abstract [24] 滕兆春,王伟斌,郑文达. 温度影响下Winkler-Pasternak弹性地基上多孔FGM矩形板的自由振动分析[J]. 工程力学,2022,39(4):246-256. doi: 10.6052/j.issn.1000-4750.2021.02.0152TENG Z C,WANG W B,ZHENG W D. Free vibration analyses of porous fgm rectangular plates on a winkler-Pasternak elastic foundation considering the temperature effect[J]. Engineering Mechanics,2022,39(4):246-256. (in Chinese with English abstract doi: 10.6052/j.issn.1000-4750.2021.02.0152 [25] 欧阳煜,夏登科. Pasternak双参数地基上Euler-Bernoulli裂纹梁弯曲的解析解[J]. 力学季刊,2021,42(4):685-695.OUYANG Y,XIA D K. Analytical solution of bending deformation of the Euler-bernoulli cracked beam on Pasternak two-parameter foundation[J]. Chinese Quarterly of Mechanics,2021,42(4):685-695. (in Chinese with English abstract [26] 王满,马建军,韩书娟. 考虑有限深度土体运动的Winkler地基梁1/2次谐波共振响应分析[J]. 振动与冲击,2020,39(11):165-170.WANG M,MA J J,HAN S J. 1/2 sub-harmonic resonance of beams on Winkler foundation with consideration of finite-depth soil motion[J]. Journal of Vibration and Shock,2020,39(11):165-170. (in Chinese with English abstract [27] 蒲育,滕兆春. Winkler-Pasternak弹性地基梁自由振动的二维弹性分析[J]. 计算力学学报,2016,33(2):182-187. doi: 10.7511/jslx201602007PU Y,TENG Z C. Two-dimensional elastic analysis for free vibration of beams set on winkler-Pasternak elastic foundations[J]. Chinese Journal of Computational Mechanics,2016,33(2):182-187. (in Chinese with English abstract doi: 10.7511/jslx201602007 [28] 肖世国,夏才初,朱合华,等. 管幕内箱涵顶进中顶部管幕竖向变形预测[J]. 岩石力学与工程学报,2006,25(9):1887-1892. doi: 10.3321/j.issn:1000-6915.2006.09.023XIAO S G,XIA C C,ZHU H H,et al. Vertical deformation prediction on upper pipe-roof during a box culvert being pushed within a pipe-roof[J]. Chinese Journal of Rock Mechanics and Engineering,2006,25(9):1887-1892. (in Chinese with English abstract doi: 10.3321/j.issn:1000-6915.2006.09.023 [29] 夏才初,阙程柯,刘 胜. 顶进箱涵全断面置换管幕工法中钢管幕内力研究及实例分析[J]. 岩土力学,2011,32(12):3555-3560. doi: 10.3969/j.issn.1000-7598.2011.12.004XIA C C,QUE C K,LIU S. Study of internal forces and case study of pipe-roof for box culvert jacking and replacement full face pipe- roof method[J]. Rock and Soil Mechanics,2011,32(12):3555-3560. (in Chinese with English abstract doi: 10.3969/j.issn.1000-7598.2011.12.004 [30] ZHANG Z Q,LI H Y,LIU H Y,et al. Load transferring mechanism of pipe umbrella support in shallow-buried tunnels[J]. Tunnelling and Underground Space Technology,2014,43:213-221. doi: 10.1016/j.tust.2014.05.018 [31] JUNEJA A,HEGDE A,LEE,F H,et al. Centrifuge modelling of tunnel face reinforcement using forepoling[J]. Tunnelling and Underground Space Technology,2010,25(4):377-381. doi: 10.1016/j.tust.2010.01.013 [32] 黄华,巩江峰,邸成,等. 铁路隧道超前管棚变形规律及参数研究[J]. 铁道工程学报,2019,36(12):65-70.HUANG H,GONG J F,DI C,et al. Research on the deformation law and parameters of advanced pipe shed for railway tunnel[J]. Journal of Railway Engineering Society,2019,36(12):65-70. (in Chinese with English abstract [33] 董新平,彭中和. 浅埋地下工程管棚法施工中合理管棚直径分析[J]. 岩土工程学报,2007,29(9):1355-1360. doi: 10.3321/j.issn:1000-4548.2007.09.012DONG X P,PENG H Z. Optimum diameter analysis of pipe roofs applied in underground engineering with shallow overburden[J]. Chinese Journal of Geotechnical Engineering,2007,29(9):1355-1360. (in Chinese with English abstract doi: 10.3321/j.issn:1000-4548.2007.09.012 [34] 黄炫茜. 青岛地铁上软下硬地层浅埋暗挖施工稳定性分析[D]. 辽宁大连:大连海事大学,2023.HUANG X Q. Stability analysis of shallow excavation in soft and hard stratum of Qingdao subway[D]. Dalian Liaoning: Dalian Maritime University,2023. (in Chinese with English abstract [35] 李勋. 超浅埋暗挖车站洞桩法施工横向管幕承载机理及地表沉降预测方法研究[D]. 济南:山东建筑大学,2023.LI X. Study on the bearing mechanism of transverse pipe curtain and the prediction method of surface settlement in the construction of ultra-shallow buried underground excavation station hole pile method[D]. Jinan: Shandong Jianzhu University,2023. (in Chinese with English abstract [36] 朱雁飞,毕湘利,郭彦,等. 富水饱和软土地层轨道交通地下车站暗挖工法研究综述[J]. 隧道与轨道交通,2021(增刊1):1-7.ZHU Y F,BI X L,GUO Y,et al. Summary of research on underground excavation method of rail transit underground station in water-rich saturated soft soil stratum[J]. Tunnel and Rail Transit,2021(S1):1-7. (in Chinese) [37] 袁贝,陈卫忠. 城市市区地下空间暗挖工法适应性研究[J]. 地下空间与工程学报,2020,16(4):1172-1182.YUAN B,CHEN W Z. Study on adaptability of underground excavation method in urban area[J]. Chinese Journal of Underground Space and Engineering,2020,16(4):1172-1182. (in Chinese with English abstract [38] 黄慷,吴小建,王红卫. 软土大型地下空间管幕-冻结-注浆暗挖工艺研究[J]. 地下空间与工程学报,2019,15(增刊2):729-742.HUANG K,WU X J,WANG H W. Study on pipe curtain-freezing-grouting underground excavation technology for large underground space in soft soil[J]. Chinese Journal of Underground Space and Engineering,2019,15(S2):729-742. (in Chinese) [39] 孙金,周凯. 下穿铁路路基双重置换管幕法地表沉降分析[J]. 地下空间与工程学报,2015,11(5):1271-1275,1288.SUN J,ZHOU K. Analysis on ground settlements of pipe-roof by dual replacement under railway roadbed[J]. Chinese Journal of Underground Space and Engineering,2015,11(5):1271-1275+1288. (in Chinese with English abstract [40] 胡玉银,吴欣之,袁勇,等. 地下立体交通工程中的箱涵顶进双重置换施工工法研究[J]. 建筑施工,2010,32(2):85-87.HU Y Y,WU X Z,YUAN Y,et al. Research on double replacement construction method of box culvert jacking in underground three-dimensional traffic engineering [J]. Building construction,2010,32(2):85-87. (in Chinese with English abstract [41] 赵洪岩,张勇,陈峰军,等. 箱涵顶进置换管幕工法土体变形分布式光纤监测研究[J]. 岩土工程学报,2012,34(7):1355-1361.ZHAO H Y,ZHANG Y,CHEN F J,et al. Distributed optic fiber sensors for soil deformation monitoring for construction method of box culverts being pushed to replace pipe roofs[J]. Chinese Journal of Geotechnical Engineering,2012,34(7):1355-1361. (in Chinese with English abstract -

下载:

下载: